Polishing device for computer keyboard

A computer and keyboard technology, applied in the field of computer keyboard grinding devices, can solve the problems affecting the grinding effect of the grinding wheel and the poor dust suction effect, and achieve the effects of facilitating regular and effective cleaning, reducing the shaking frequency and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

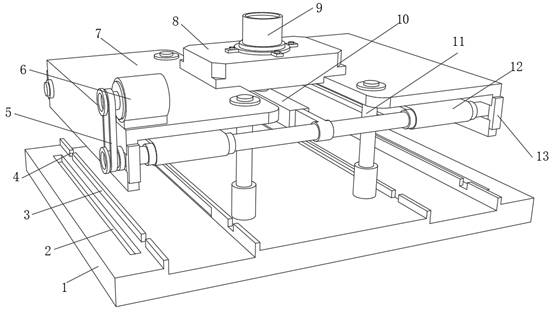

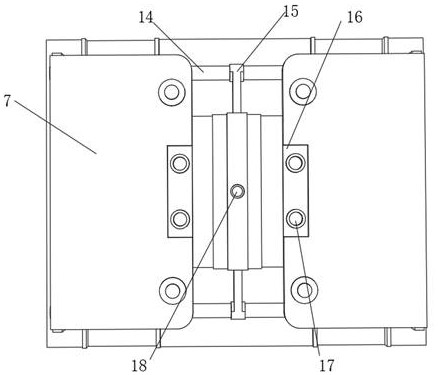

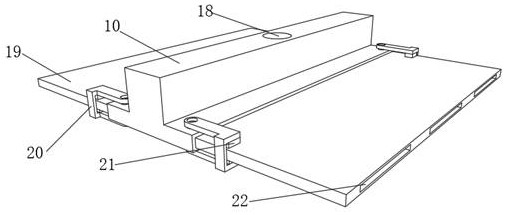

[0033] A grinding device for computer keyboards, such as Figure 1-5As shown, including a base 1, the outer walls on both sides of the top of the base 1 are respectively provided with card slots 2, and the top outer wall of the base 1 near the two card slots 2 is provided with a material storage tank, and the two material storage tanks Limiting plates 3 are welded to the top outer walls on both sides, and limiting holes 4 are opened on the outer walls on both sides of each limiting plate 3, and the outer walls of two relatively nearest limiting plates 3 are provided with inclined holes. 1. Four hydraulic cylinders 11 are respectively threaded on the middle outer wall of the top, and the piston rod ends of every two hydraulic cylinders 11 are fixed with the same L-shaped baffle 7 through threads, and the outer walls on both sides of each L-shaped baffle 7 There are guide grooves, and the same rotating rod 14 is fixed through bearings in every two relative guiding grooves, and t...

Embodiment 2

[0039] A grinding device for computer keyboards, such as Figure 5 As shown, in order to prevent the dust from concentrating into the dust guide coil 28 and causing its internal blockage; this embodiment makes the following improvements on the basis of embodiment 1: the buffer assembly includes three choke fans 29, more than three fixed plate 30, rotating shaft 31, limit cap 32 and more than three auxiliary cutting plates 33, and rotating shaft 31 is connected to the bottom circumferential inner wall of dust collecting drum 27 by more than three fixing plates 30, more than three auxiliary The cutting plate 33 is welded on the inner wall of the top circumference of the dust collection drum 27, the three choke fans 29 are respectively welded on the outer circumference wall of the rotating shaft 31, and the limit cap 32 is fixed on the top of the rotating shaft 31 by threads; 27, it will drive the choke fan 29 on the rotating shaft 31 to rotate. At this time, the flow speed of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com