Automatic troweling machine capable of vertical slotting

A vertical seam, automatic technology, applied in the processing of building materials, construction, building structure, etc., can solve the problem of inability to realize automatic plastering, etc., and achieve the effect of compact structure, good plastering effect and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

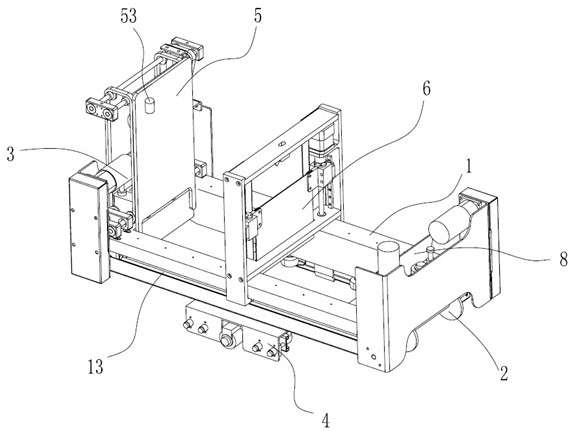

[0047] This example discloses an automatic grouting machine only used for vertical joint grouting.

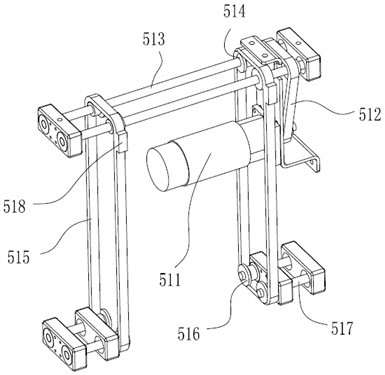

[0048] Such as figure 1 As shown, the trowel disclosed in this embodiment includes a frame 1, a traveling device 2, a driving device 3, a guiding device 4, a pulp inserting device 5, a scraping device 6 and a control system (not shown in the figure). The inside of the frame 1 forms a cavity with openings at the upper and lower ends for the mortar to be put into. The frame 1 is provided with a traverse module 13, the traveling device 2 is arranged under the frame 1, the driving device 3 is connected with the traveling device 2 to control the traveling device 2 to automatically walk on the brick surface, and the guiding device 4 is arranged on two sides below the frame 1. The sides are close to the two sides of the wall tiles. The control system is controlled and connected with the drive device 3, the traverse module 13 and the pulp inserting device 5. The squeegee device 6 is...

Embodiment 2

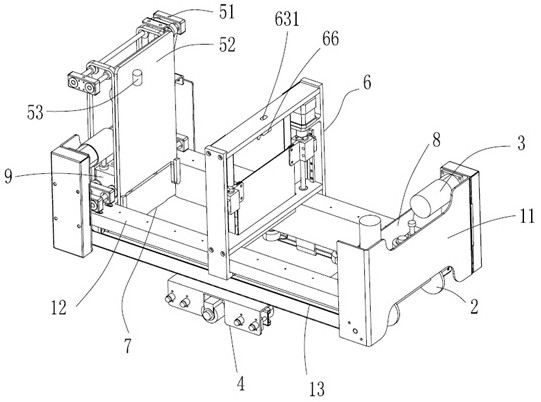

[0056] This example discloses a grouting machine that can not only grout vertical joints, but also grout horizontal surfaces.

[0057] Such as image 3 , Figure 4 As shown, the trowel machine disclosed in this embodiment includes a frame 1, a traveling device 2, a driving device 3, a guiding device 4, a pulp inserting device 5, a scraping device 6, a troweling part 7 and a control system (not shown in the figure). show).

[0058] The inside of the frame 1 forms a cavity with openings at the upper and lower ends for the mortar to be put into. The frame 1 is provided with a traverse module 13, the traveling device 2 is arranged under the frame 1, the driving device 3 is connected with the traveling device 2 to control the traveling device 2 to automatically walk on the brick surface, and the guiding device 4 is arranged on two sides below the frame 1. The sides are close to the two sides of the wall tiles. The control system is controlled and connected with the drive device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com