Filtering type joint for ball valve

A filter type, ball valve technology, applied in the field of environmental engineering, can solve problems such as unfavorable daily use, water pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

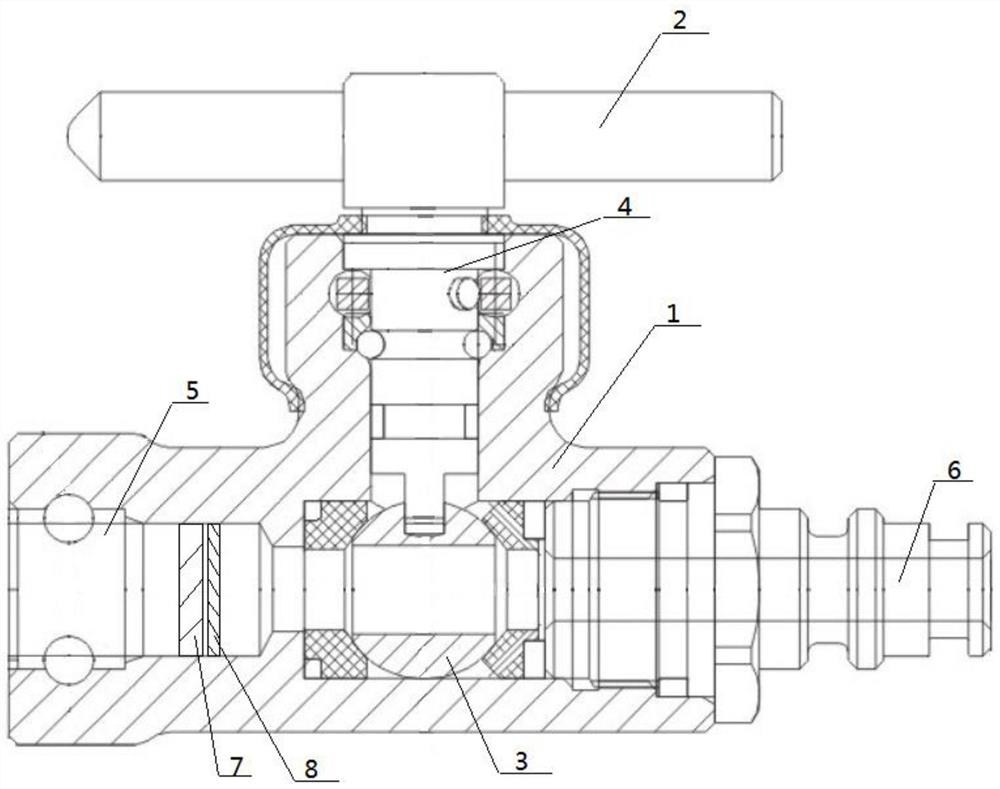

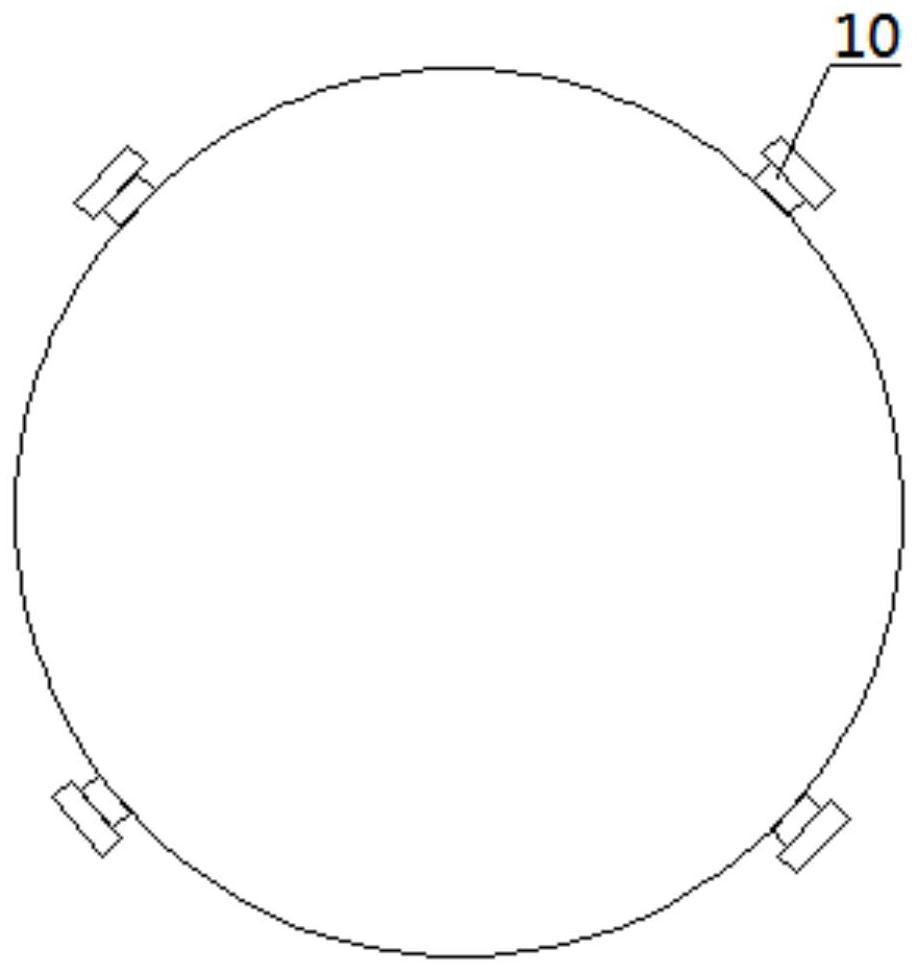

[0023] figure 1 It is a structural schematic diagram of the first embodiment of the filter joint of the present invention, image 3 It is a schematic structural view of the ion exchange layer in the present invention. As shown in Figure 1, the filter part includes an ion exchange layer 7 and a sterilizing layer 8. The ion exchange layer 7 and the sterilizing layer 8 are placed in the cavity in sequence, and the ion exchange layer 7 Four installation buckles are evenly spaced on the side connecting the sterilization layer 8 and the cavity, and the cavity is provided with a sliding groove for buckle access at the corresponding position of the buckle, and the ion exchange layer and the sterilization layer pass through The sliding groove is fitted with the corresponding mounting buckle to be slidably installed into the cavity, and the ion exchange layer is attached to the exchange filter using polystyrene ion exchange resin with exchange properties, such as image 3 The side of t...

Embodiment 2

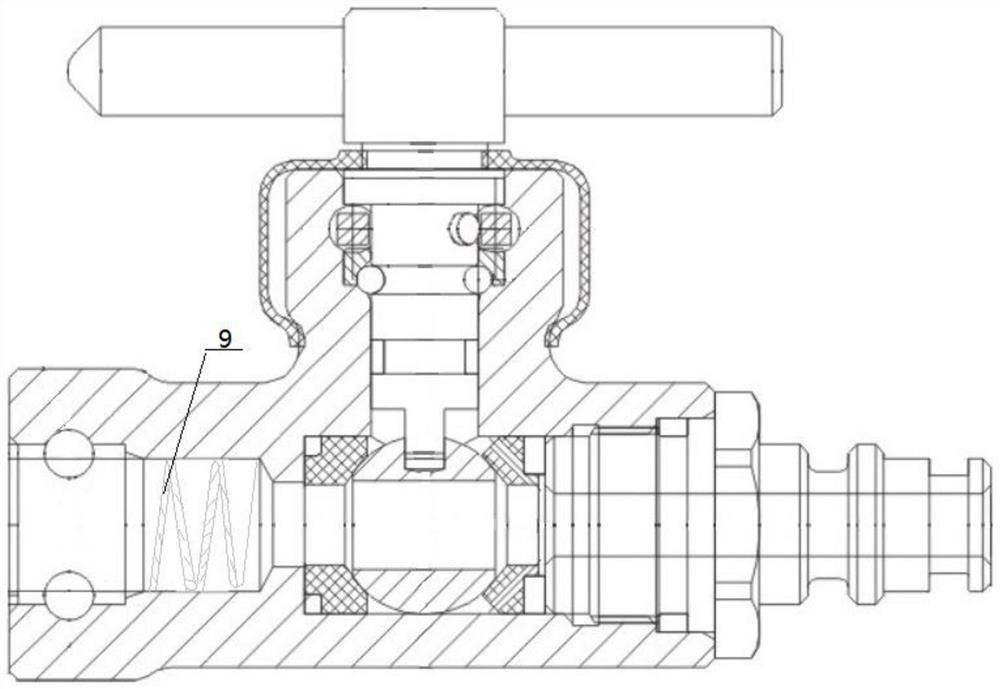

[0025] figure 2 It is a structural schematic diagram of the second embodiment of the filter joint of the present invention, as figure 2 The shown filter part comprises a spiral filter layer 9, one end of the spiral filter layer 9 is fixedly connected to the end of the cavity close to the ball valve, and the transverse length of the filter layer is consistent with the length of the cavity, and the other end of the filter layer is One end is connected to the end of the cavity close to the water inlet. The filter surface of the filter layer is uniformly equipped with granular activated carbon fibers. The water flow from the water inlet enters the ball valve through the spiral filter layer and is transferred to the water outlet. Compared with the method in Example 1, this solution can filter more adsorbable impurities in water, but lacks the effect of ion exchange resin, and is suitable for plant irrigation.

[0026] The installation method of this scheme is that there is a spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com