IBC barrel breather valve

A technology of breathable valves and breathable pads, which is applied in valve details, safety valves, balance valves, etc., can solve problems such as freezing and difficult loading and unloading of internal urea, and achieve the effect of improving heat preservation and reducing occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

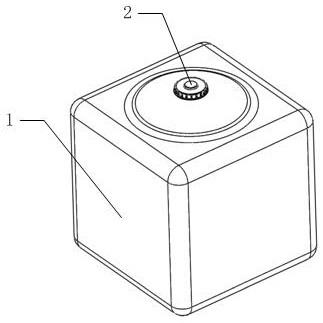

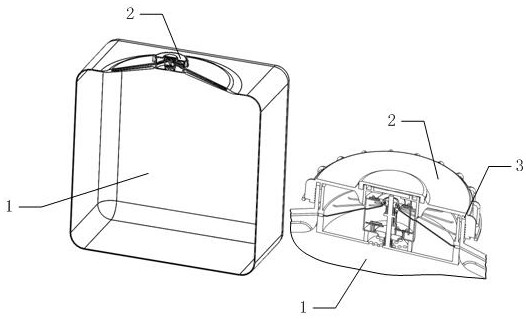

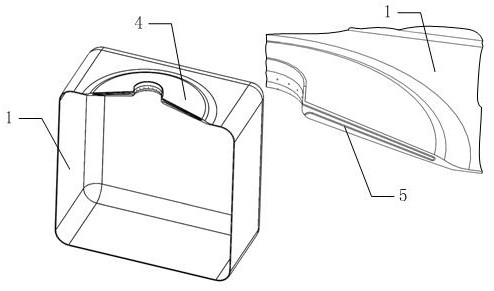

[0049] Such as Figure 4 , 5 As shown, it includes a valve core 14, a breathable cushion 12, a dust cover 10, wherein as Figure 12 As shown, the spool 14 has a mounting plate 19, the mounting plate 19 has a circular hole 18, and one side of the mounting plate 19 has a mounting groove 13; as Figure 5 As shown, the spool 14 is installed on the IBC barrel cover 2; as Figure 8 , 9 As shown, the air-permeable pad 12 is nested and installed in the installation groove 13, and the dust cover 10 is installed on the IBC barrel cover 2, and there is a gap between the dust-proof cover 10 and the air-permeable pad 12; Figure 5 , 11 As shown, the side of the valve core 14 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com