Clamping temperature measuring device

A technology of temperature measuring device and clamping cavity, which is applied in the field of circuit breaker temperature state detection device, can solve the problems of cumbersome operation, damage to electric equipment, inconvenient use, etc., and achieve the effect of simple assembly process, fast assembly, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

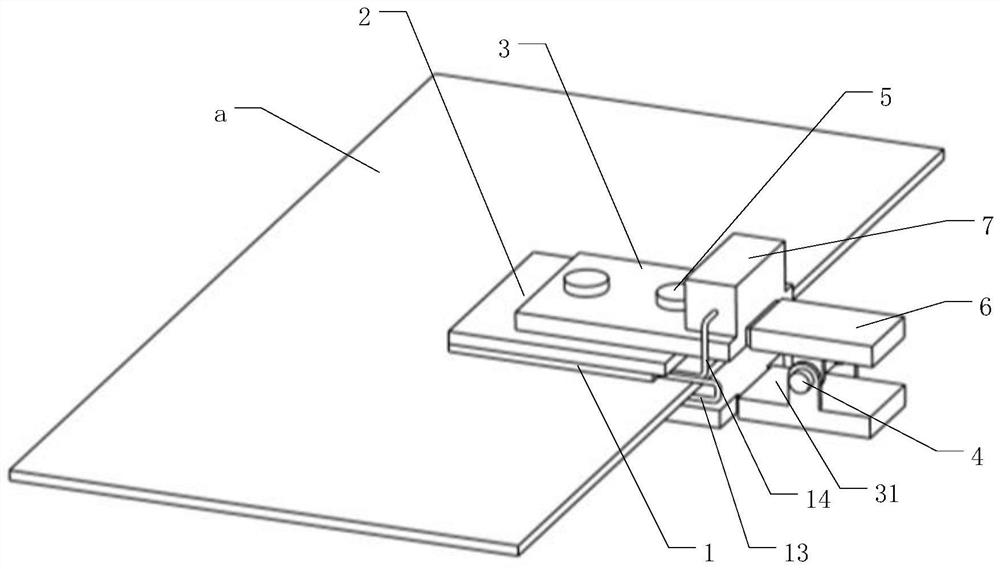

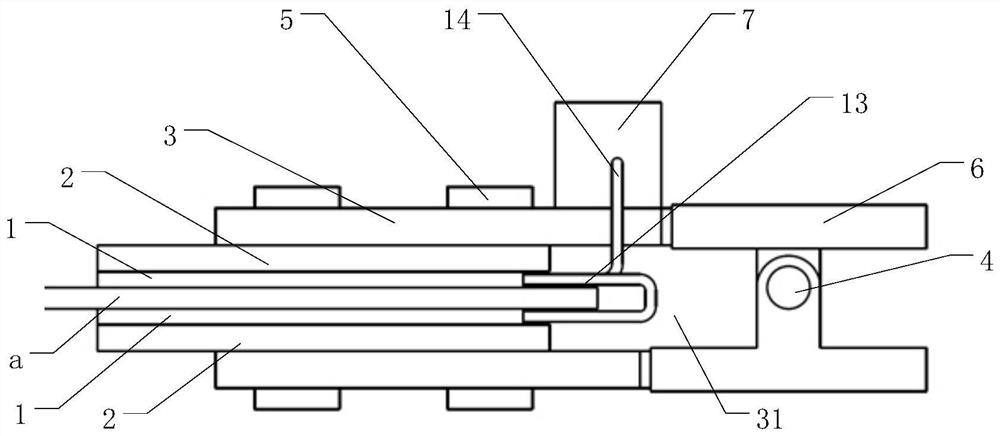

[0023] The following is attached Figures 1 to 4 The given examples further illustrate the specific implementation of a clamping temperature measuring device of the present invention. A clamping temperature measuring device of the present invention is not limited to the description of the following embodiments.

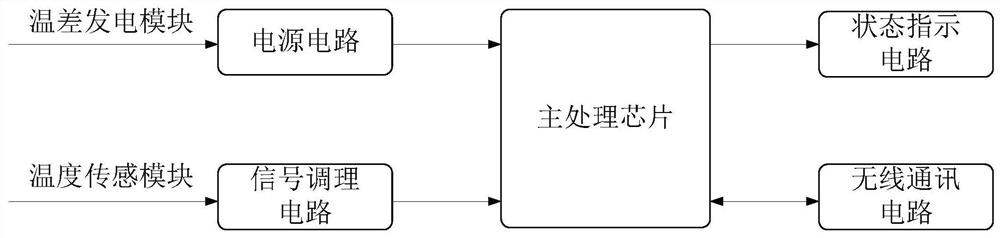

[0024] A clamping temperature measuring device, comprising a thermoelectric power generation module, a temperature sensing module, a controller module 7 and a clamping module; power supply, the temperature sensing module is used to sense the temperature of the power copper bar a and transmit the temperature signal to the controller module 7, the controller module 7 processes and converts the temperature signal transmitted by the temperature sensing module and transmits it to the external receiving terminal, The clamping module integrates the thermoelectric power generation module, the temperature sensing module and the controller module 7 and then connects them to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com