Method for quickly inspecting mechanical property of twisted steel

A technology of steel mechanics and inspection methods, which is applied in the field of smelting, can solve problems such as process optimization, adjustment difficulties, weakening of dislocations and dislocation hindrance, and lagging mechanical performance inspections, so as to save natural cooling time, have good performance correspondence, The effect of overcoming the inaccuracy problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

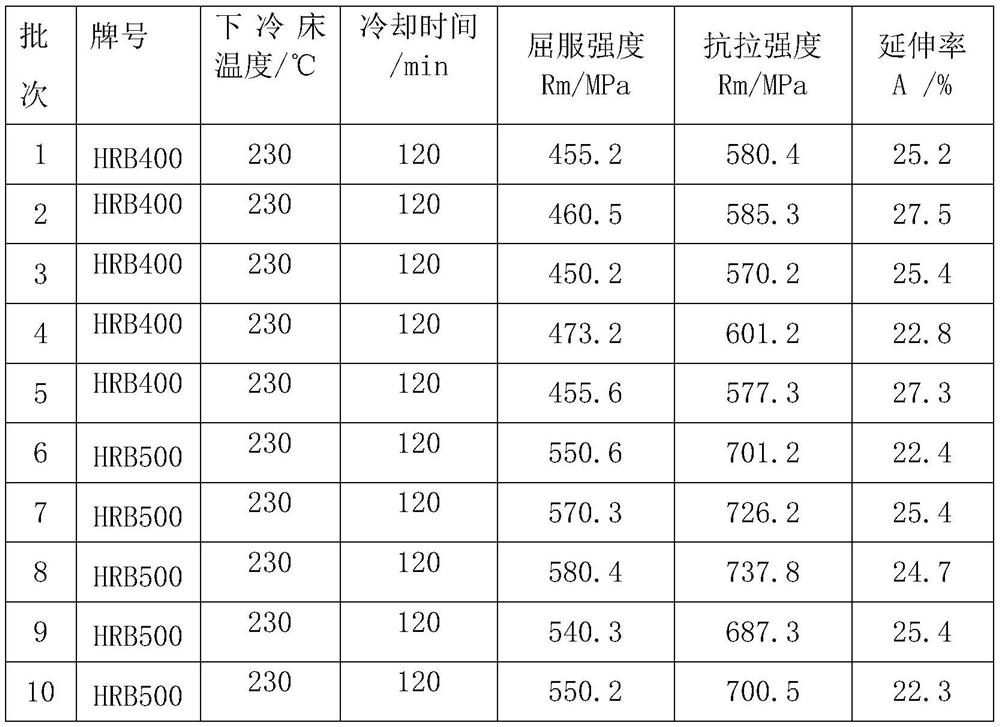

[0019] A quick testing method for the mechanical properties of threaded steel bars, comprising the following steps:

[0020] (1) Take 10 batches of HRB400 and HRB500 threaded steel bars of the same specification Different batches of hot-rolled threaded steel bars were naturally cooled to room temperature after rolling as comparison samples;

[0021] (2) Rapidly cool the hot-rolled threaded steel bar to room temperature by means of air cooling, and inspect the yield strength Rel, tensile strength Rm, and elongation A of the corresponding sample batches, and take the average value of 2 samples;

[0022] (3) Rapidly cool the hot-rolled threaded steel bar to room temperature by means of water cooling, and inspect the yield strength Rel, tensile strength Rm, and elongation A of the corresponding sample batches, and take the average value of 2 samples;

[0023] According to the method of GB / T1499-2007, the mechanical properties are tested, and the results are shown in Table 1-3; ...

Embodiment 2

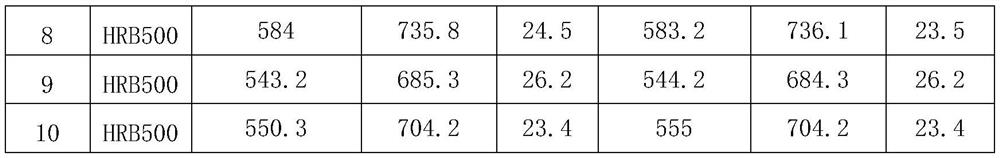

[0033] A quick testing method for the mechanical properties of threaded steel bars, comprising the following steps:

[0034] (1) Take 10 batches of HRB400 and HRB500 threaded steel bars of the same specification Different batches of hot-rolled threaded steel bars were naturally cooled to room temperature after rolling as comparison samples;

[0035] (2) Rapidly cool the hot-rolled threaded steel bar to room temperature by means of air cooling, and inspect the yield strength Rel, tensile strength Rm, and elongation A of the corresponding sample batches, and take the average value of 2 samples;

[0036] (3) Rapidly cool the hot-rolled threaded steel bar to room temperature by means of water cooling, and inspect the yield strength Rel, tensile strength Rm, and elongation A of the corresponding sample batches, and take the average value of 2 samples;

[0037] Test the mechanical properties according to the method of GB / T1499-2007, and the results are shown in Table 4-6;

[0038...

Embodiment 3

[0047] A quick testing method for the mechanical properties of threaded steel bars, comprising the following steps:

[0048] (1) Take 10 batches of HRB400 and HRB500 threaded steel bars of the same specification Different batches of hot-rolled threaded steel bars were naturally cooled to room temperature after rolling as comparison samples;

[0049] (2) Rapidly cool the hot-rolled threaded steel bar to room temperature by means of air cooling, and inspect the yield strength Rel, tensile strength Rm, and elongation A of the corresponding sample batches, and take the average value of 2 samples;

[0050] (3) Rapidly cool the hot-rolled threaded steel bar to room temperature by means of water cooling, and inspect the yield strength Rel, tensile strength Rm, and elongation A of the corresponding sample batches, and take the average value of 2 samples;

[0051] Test the mechanical properties according to the method of GB / T1499-2007, and the results are shown in Table 7-9;

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com