Wire and cable insulation injection molding device

An insulation injection molding, wire and cable technology, applied in the direction of conductor/cable insulation, cable/conductor manufacturing, circuit, etc., can solve the problems of uneven surface of cable products, poor quality, and coating can not cover the surface of the cable evenly, to achieve uniformity Injection molding work, good quality of finished product, easy to take full advantage of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

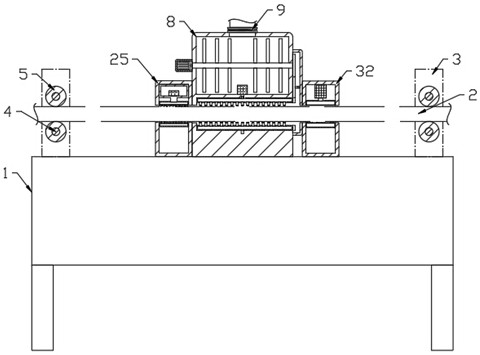

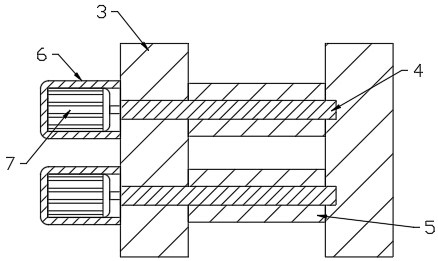

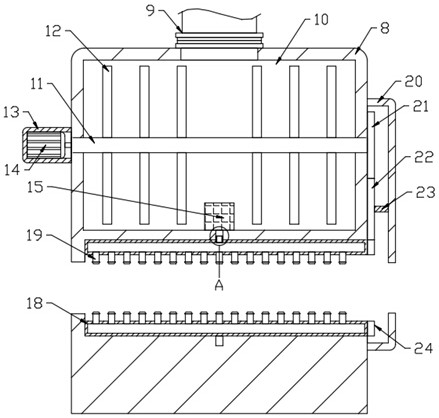

[0027] see Figure 1-7 , a wire and cable insulation injection molding device, including a workbench 1 and a cable 2 moving on the upper side of the workbench 1, the two sides of the workbench 1 are respectively provided with a column 3, and the column 3 is provided with a drive for transporting and driving the cable 2 Assemblies, the upper end of the workbench 1 is fixedly connected with the injection molding seat 8, and the injection molding seat 8 is provided with a cavity 10, and the cavity 10 is provided with a stirring assembly for stirring the injection molding raw materials, and the lower side of the injection molding seat 8 is rotatably connected with an annular injection molding box 18 The inner side of the annular injection molding box 18 is provided with a number of nozzles 19, the cavity 10 communicates with the annular injection molding box 18 through a connecting component, and the side end of the injection molding seat 8 is provided with a rotating assembly that...

Embodiment 2

[0044] This embodiment makes further improvements on the basis of Embodiment 1, and the improvements are as follows: the workbench 1 is provided with an air-drying assembly for air-drying the injection-molded cable 2, and the air-drying assembly includes an air-drying seat 32, a cooling fan 33, a connecting Pipe 34, annular blowing box 35 and orifice 37, air-drying seat 32 is fixedly connected with workbench 1, and air-drying seat 32 is provided with cooling fan 33, and the output end of cooling fan 33 is communicated with annular blowing box 35 through connecting pipe 34, and annular blowing box 35 is connected. A number of orifices 36 are provided on the inner wall of the box 35, and the cooling fan 33 provided on the air-drying seat 32 works to generate an air flow, and the air flow passes through the orifices 36 on the connecting pipe 34 and the annular blowing box 35 to air-dry the surface of the injection-molded cable 2 treatment, so that the coating on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com