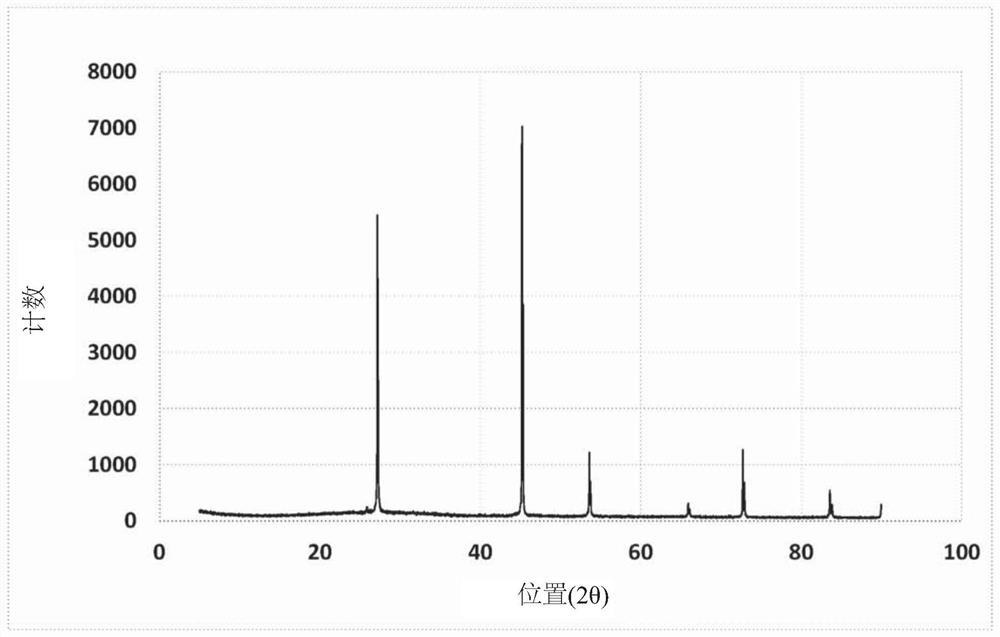

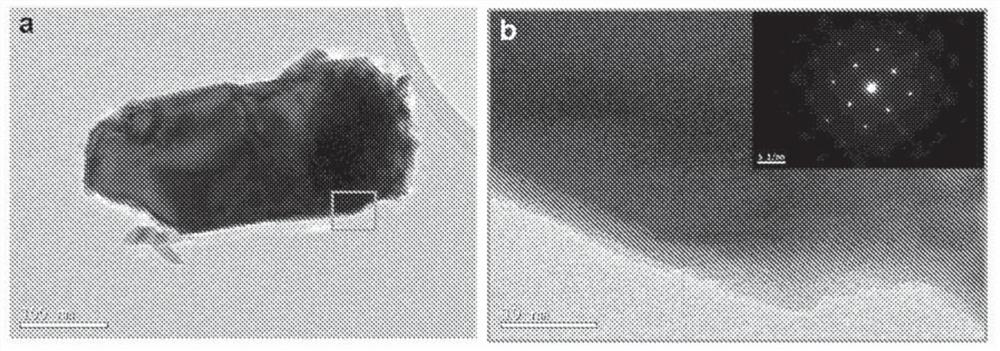

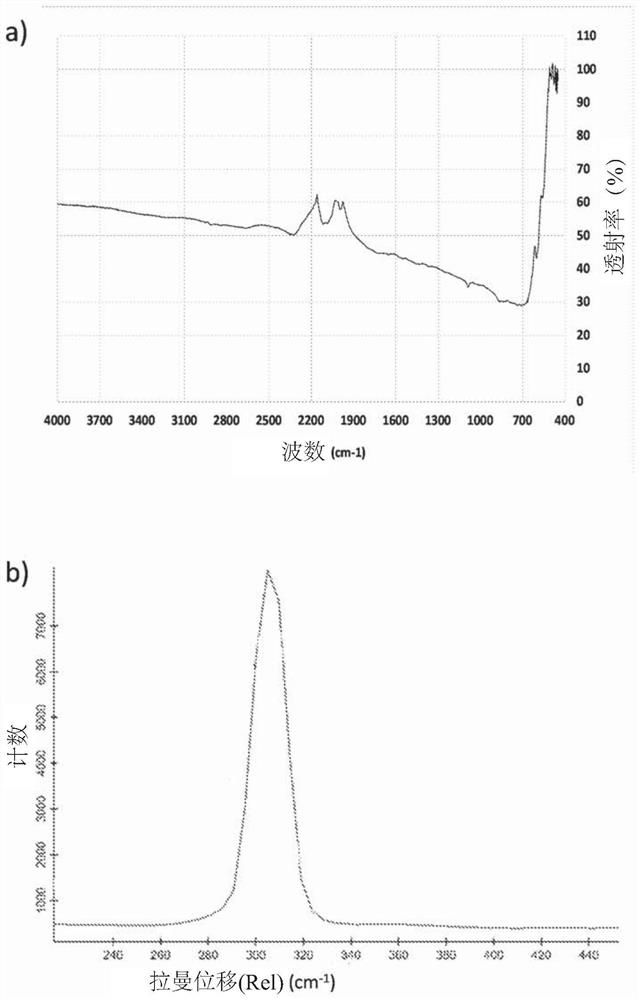

Few-layer alpha-germanium crystal, their preparation processes and uses therof

A technology of crystal and carbon number, applied in the field of α-germanium crystal in sheet form, can solve problems such as efficiency limitation and achieve the effect of less material amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] Two methods for obtaining the plate-shaped α-germanium crystals of the present invention are described.

[0080] 1. Wet grinding:

[0081] 200 mg of commercial polycrystalline alpha-germanium crystals (SmartElements or Aldrich, 99.999% pure) were placed in a steel pebble bed reactor with two-thirds of the reactor volume free. Add 1 ml mixture of water and isopropanol (2-propanol / H 2 O, the volume ratio is 4:1), and milled in the reactor at 3000rpm for 60min. The α-germanium powder obtained after grinding was vacuum-dried at 60 °C for 12 h and stored in an Ar atmosphere to prevent possible oxidation.

[0082] 2. Ultrasound:

[0083] Commercial polycrystalline α-germanium crystals (Smart-Elements or Aldrich, 99.999% pure) with an initial concentration equal to 20 g / L were prepared in a mixture of water and isopropanol (2-propanol / H 2 O, a dispersion in a volume ratio of 4:1). The dispersion was sonicated with an ultrasonic head at 400 W and 24 kHz for 45 min. The re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com