Glass bottle brimful capacity and flaw detection equipment

A defect detection and glass bottle technology, which is applied in the field of glass bottle full-mouth capacity and defect detection devices, can solve problems such as uneven thickness of bottle walls, different liquid levels, cracks in glass bottles, etc., to save manpower and material resources, speed up, and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

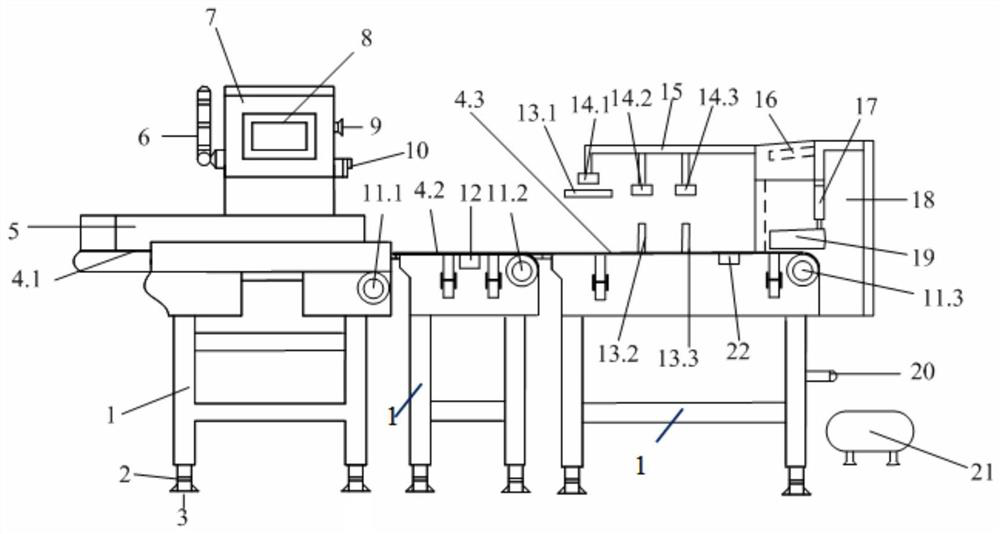

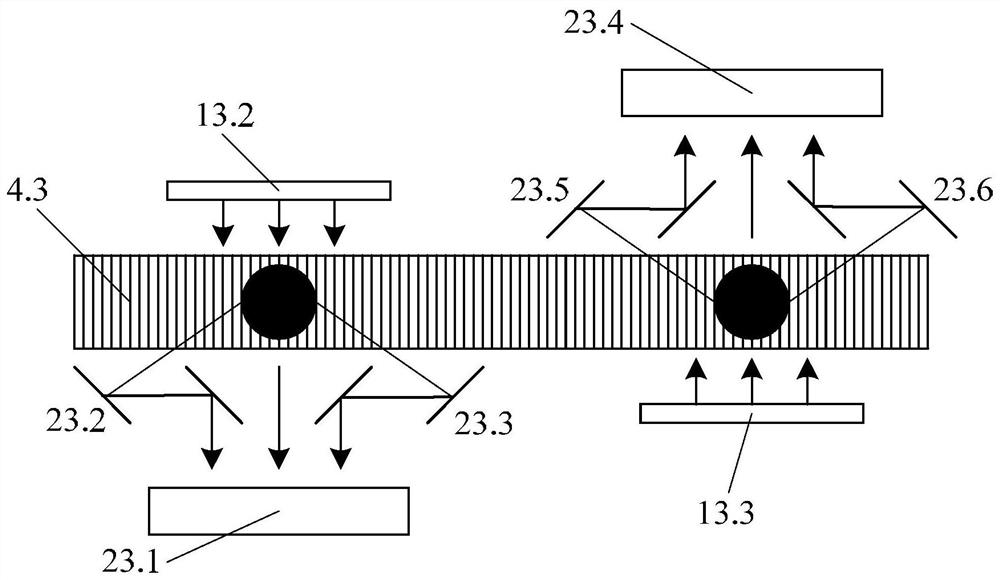

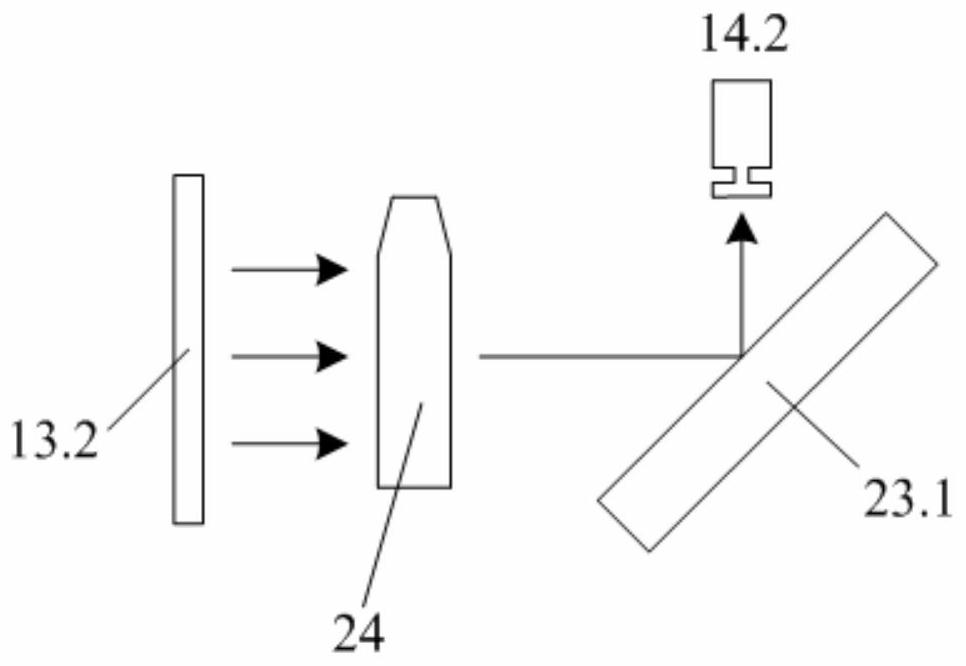

[0023] This embodiment consists of four parts: stretching section, weighing section, sorting section and automatic control system.

[0024] The distance between the glass bottles 24 from the assembly line is about 1-2cm. Because the distance between the bottles is too close, the problem of simultaneous weight measurement of multiple glass bottles 24 is likely to occur, resulting in inaccurate weight measurement of a single bottle. In order to avoid This problem occurs and needs to be stretched.

[0025] The stretching section includes a support 1, a transmission belt A4.1, a motor A11.1 and a frequency converter, the support 1 plays a supporting role, the transmission belt A4.1 is installed on the support 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com