Rolling mill high-response broken belt detection and protection method and system

A protection system and rolling mill technology, applied in metal rolling, length measuring device, metal rolling and other directions, can solve the problems of unreasonable protection strategy, loss of stranding machine, response hysteresis, etc., and achieve novel control methods and avoid stranding. Band and unwind, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The method and system for detecting and protecting high-response broken strips of rolling mills according to the present invention will be further explained and described below in conjunction with specific embodiments and accompanying drawings. However, such explanations and descriptions do not constitute improper limitations on the technical solution of the present invention.

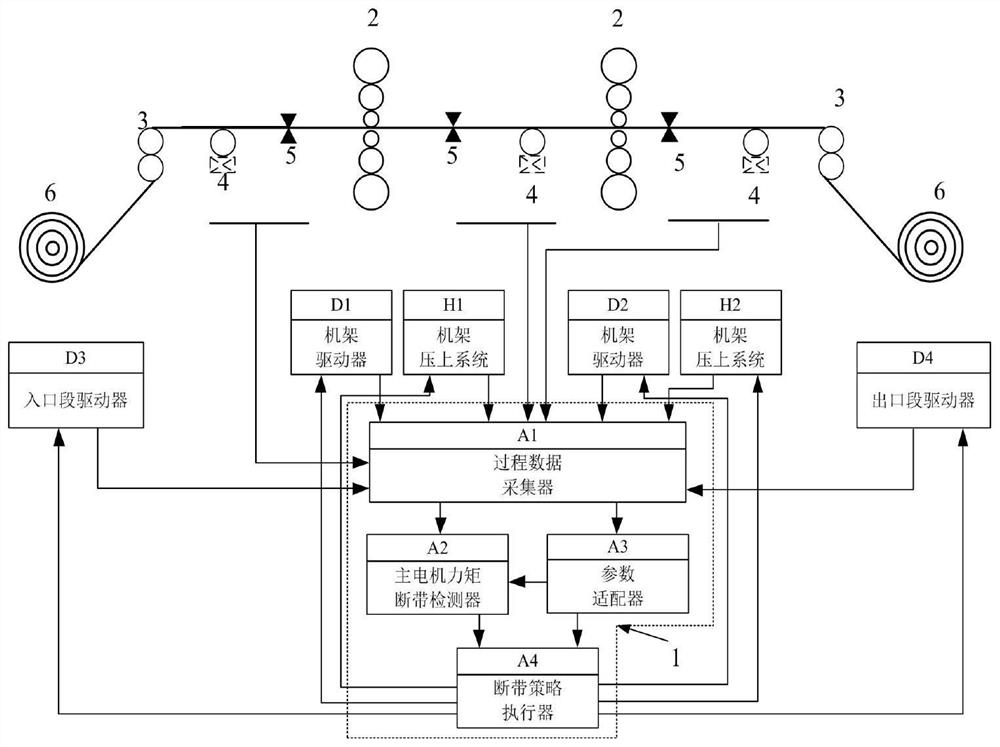

[0052] figure 1 It is a schematic diagram of the system frame of the high-response broken strip detection and protection system for a rolling mill in an embodiment of the present invention.

[0053] like figure 1 As shown, in this embodiment, the rolling mill equipment includes a rolling mill stand 2, a thickness gauge 5, a tension gauge 4, a tension roller group 3, and an uncoiler 6, and the rolling mill equipment is connected to the high-response broken strip detection and protection system of the rolling mill. Among them, the high-response broken strip detection and protection system of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com