Sleeve-shaped flat nozzle device for narrow-gap welding and using method thereof

A nozzle device and narrow gap technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of no flanging flange, poor nozzle versatility, and poor environmental adaptability, etc., to reduce gas Sealing requirements, improving the effect of gas protection, and simplifying the design of the nozzle device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062]The following describes the present invention in further detail with reference to the accompanying drawings and specific implementations, but the scope of protection of the present invention is not limited to the following embodiments. All technical solutions obtained by equivalent substitutions or equivalent transformations fall within the scope of protection of the present invention. .

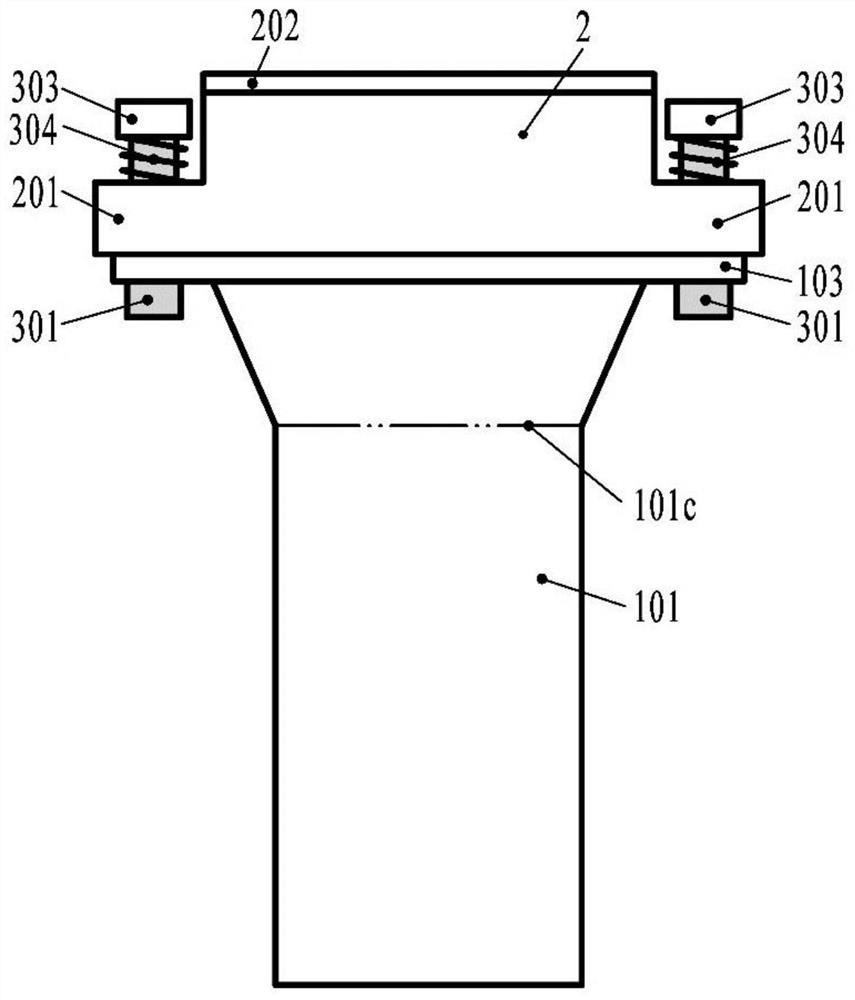

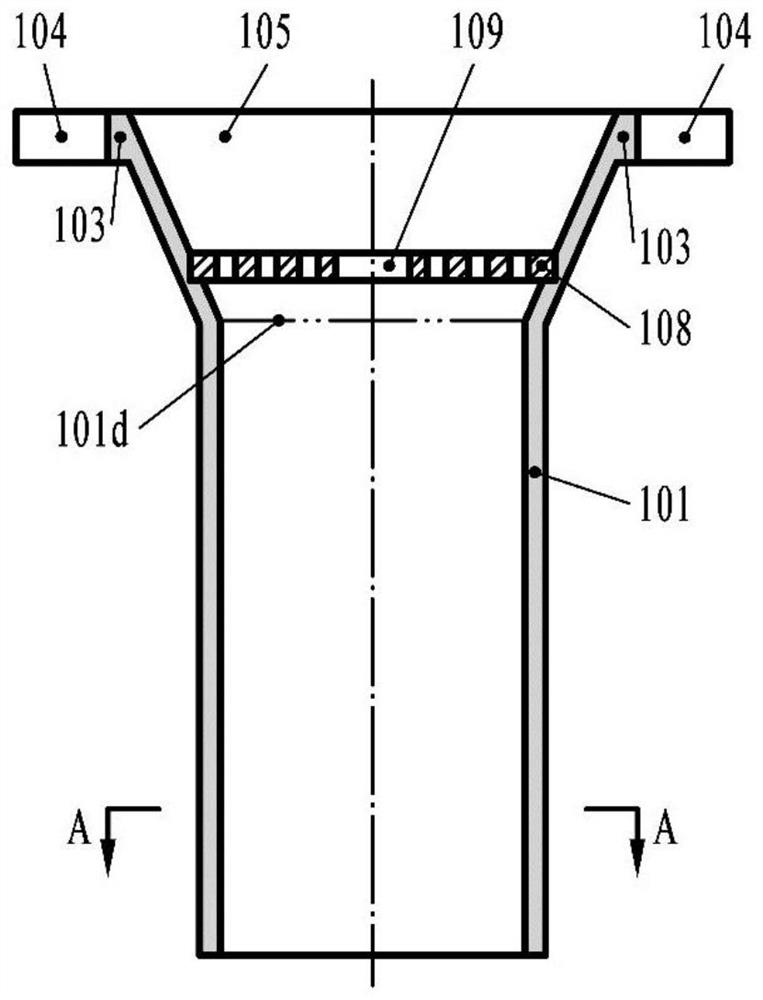

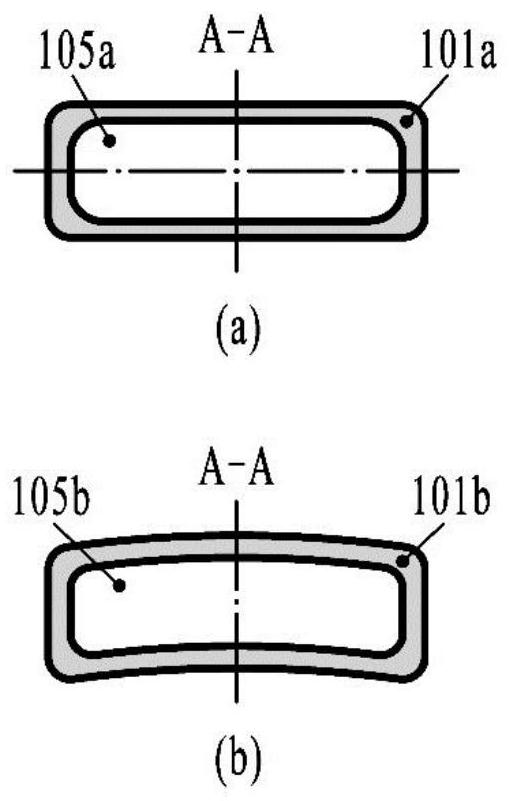

[0063]The sleeve-shaped flat nozzle device for narrow gap welding of the present invention includes a sleeve-shaped flat nozzle, a nozzle seat 2, and a screw or bolt connection mechanism, or only a sleeve-shaped flat nozzle. Wherein, the sleeve-shaped flat nozzle includes three structural forms: funnel (or funnel or funnel), straight cylinder (or straight cylinder), and stepped cylinder.

[0064]A sleeve-shaped flat nozzle device using a funnel nozzle such asfigure 1 Shown. The funnel-shaped flat nozzle is a hollow, thin-walled cylindrical body with a flat rectangular or flat waist or flat arc cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com