Plate shearing machine for metal processing

A metal processing and shearing machine technology, applied in metal processing, metal processing machinery parts, metal processing equipment, etc., can solve the problems of not installing shock absorbing devices, delaying production plans, and not being able to play the role of shock absorption, etc., to achieve high Practical value, the effect of solving poor product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

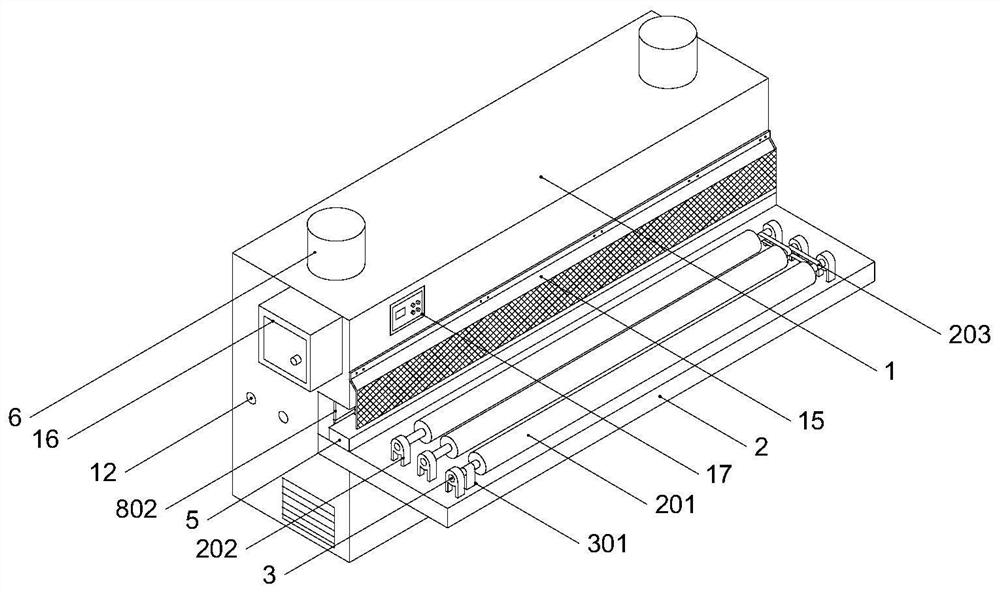

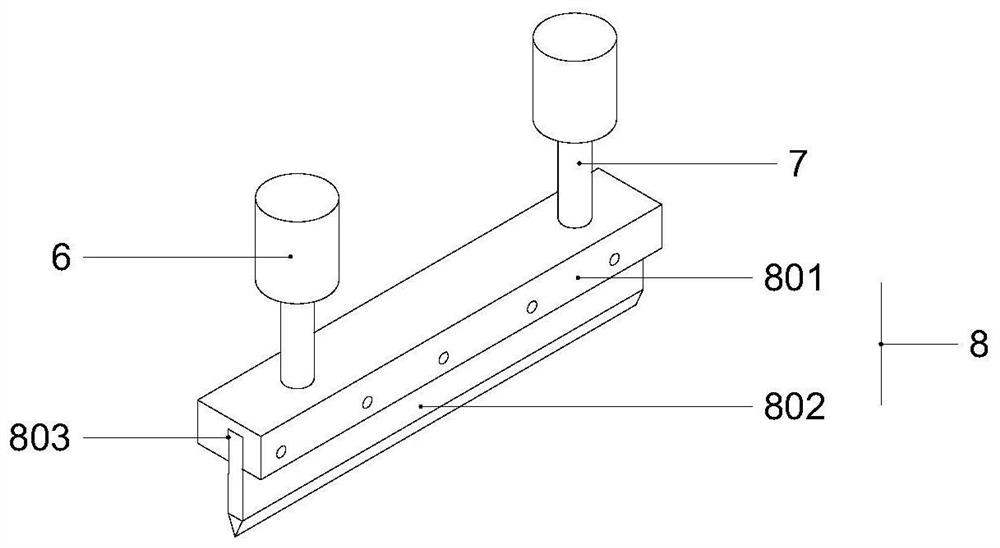

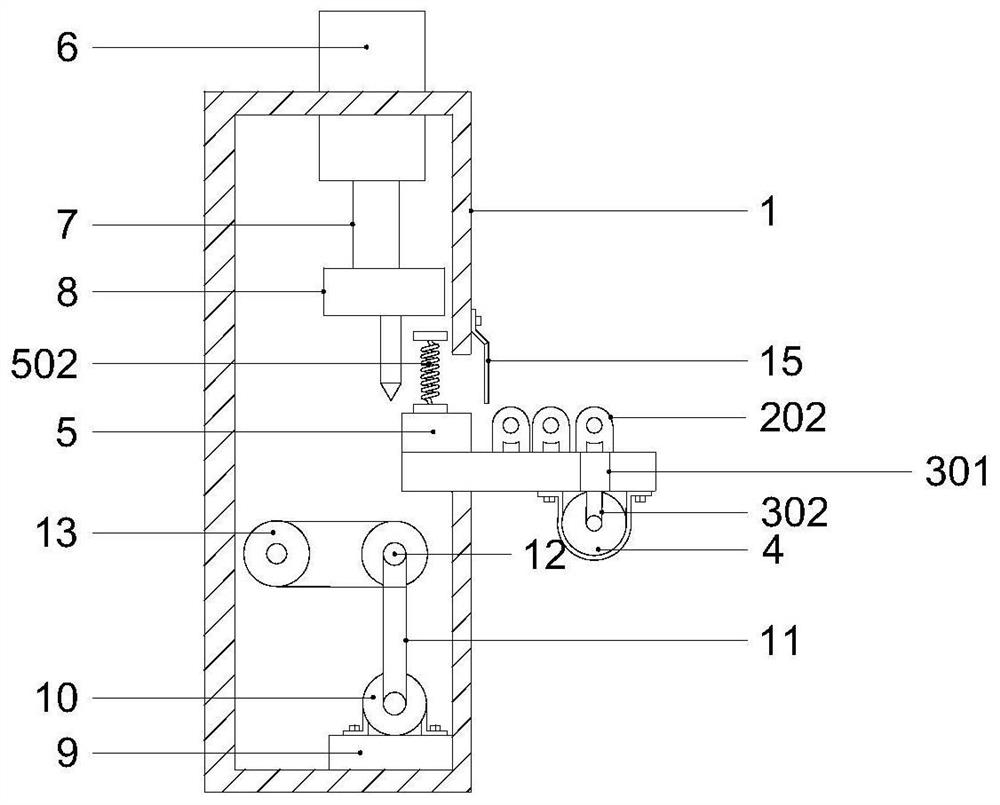

[0021] Example: such as Figure 1-4 As shown, a metal shearing machine of the present invention includes a body 1, a transport plate 2 is fixedly installed on one side of the body 1, a first transport wheel 201 is fixedly installed on the top side of the transport plate 2, and the first transport wheel 201- The first rotating shaft 3 is arranged on one side, the first motor 4 is connected to one side of the first rotating shaft 3, the shock absorbing plate 5 is fixedly installed on the other side of the top of the transport plate 2, the cylinder 6 is fixedly installed on the top of the body 1, and the bottom of the cylinder 6 The telescopic rod 7 is fixedly installed at the end, and the bottom end of the telescopic rod 7 is fixedly connected with a cutting device 8, the cutting device 8 is composed of a cutting block 801 and a cutting blade 802, the bottom end of the body 1 is fixedly installed by a fixed block 9, and the top of the fixed block 9 is fixedly installed There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com