A feeding device for automatically arranging umbrella ribs

A feeding device and automatic arrangement technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of mechanical automation production that has not yet been realized, and achieve the effect of reducing labor costs, improving conveying efficiency, and improving feeding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]In order to further explain the technical solutions of the present invention, the present invention will be described in detail below through specific embodiments.

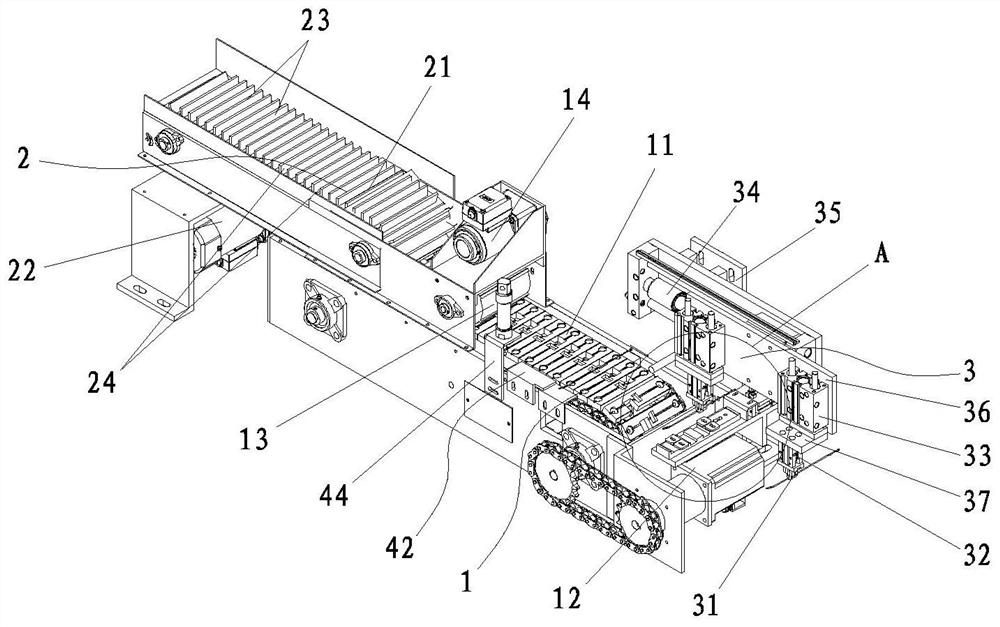

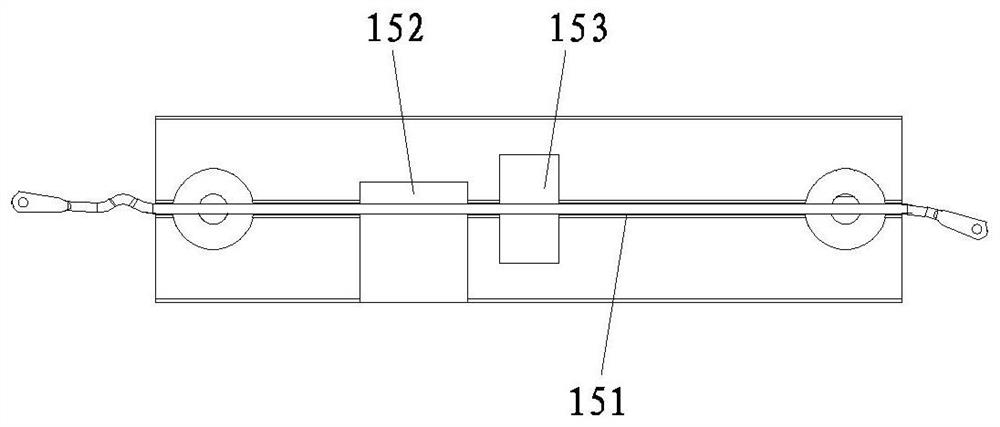

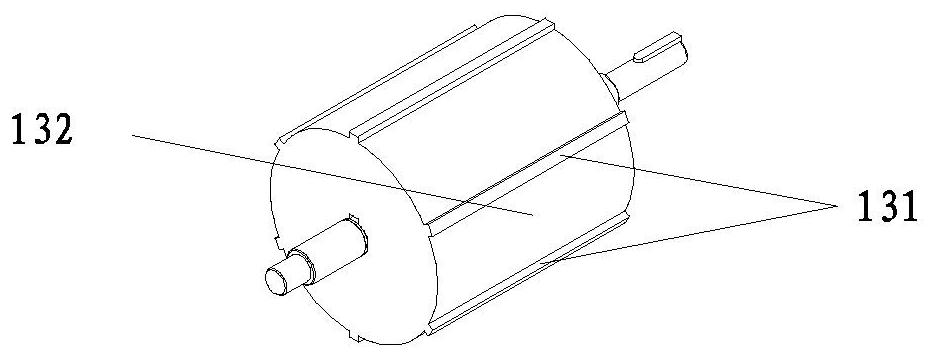

[0049] like Figure 1-6 As shown, a feeding device for automatically arranging umbrella ribs includes a discharging mechanism 1 for arranging and conveying cylindrical ribs in turn, a feeding mechanism 2 for transporting cylindrical ribs to the discharging mechanism 1, and The cylindrical rib is clamped by the discharging mechanism 1 to the clamping mechanism 3 of the cylindrical rib tooling; the feeding end of the discharging mechanism 1 corresponds to the discharging end of the feeding mechanism 2, and the clamping The mechanism 3 is located at the discharge end of the discharge mechanism 1; the discharge mechanism 1 includes a horizontally arranged discharge conveyor belt 11, and a discharge drive device 12 for driving the discharge conveyor belt 11 to run, located at the discharge conveyor belt. The dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com