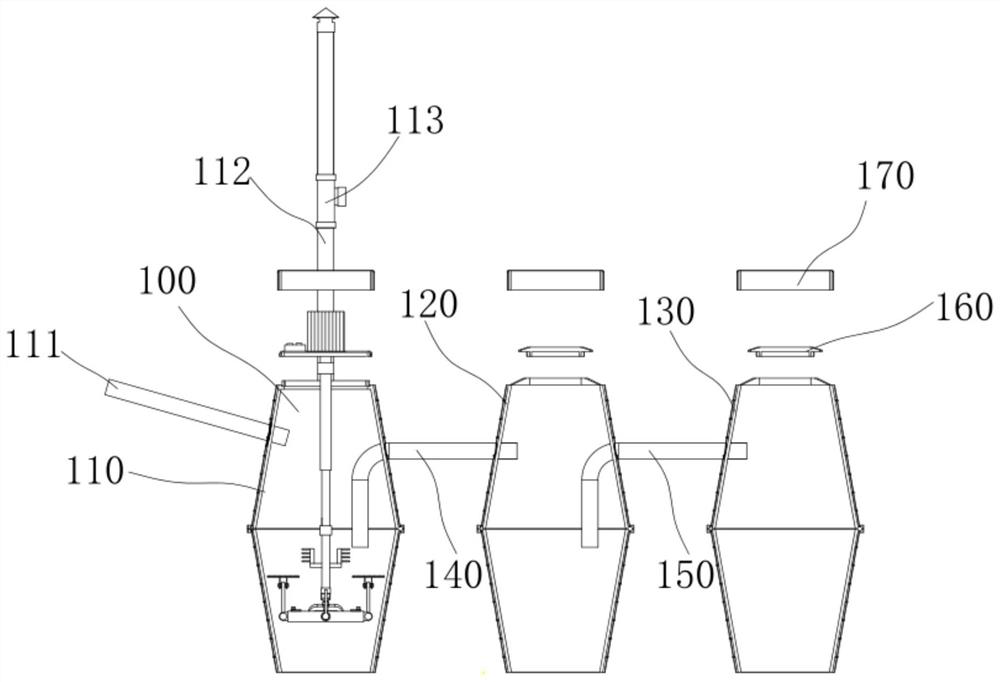

Anti-blocking three-grid septic tank capable of promoting efficient fermentation

A technology for septic tanks and septic tanks, applied in biological sludge treatment and other directions, can solve problems such as difficulty in cleaning feces, clogging, and affecting the continued decomposition of fecal residues, and achieve the effects of facilitating cleaning, improving safety and sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

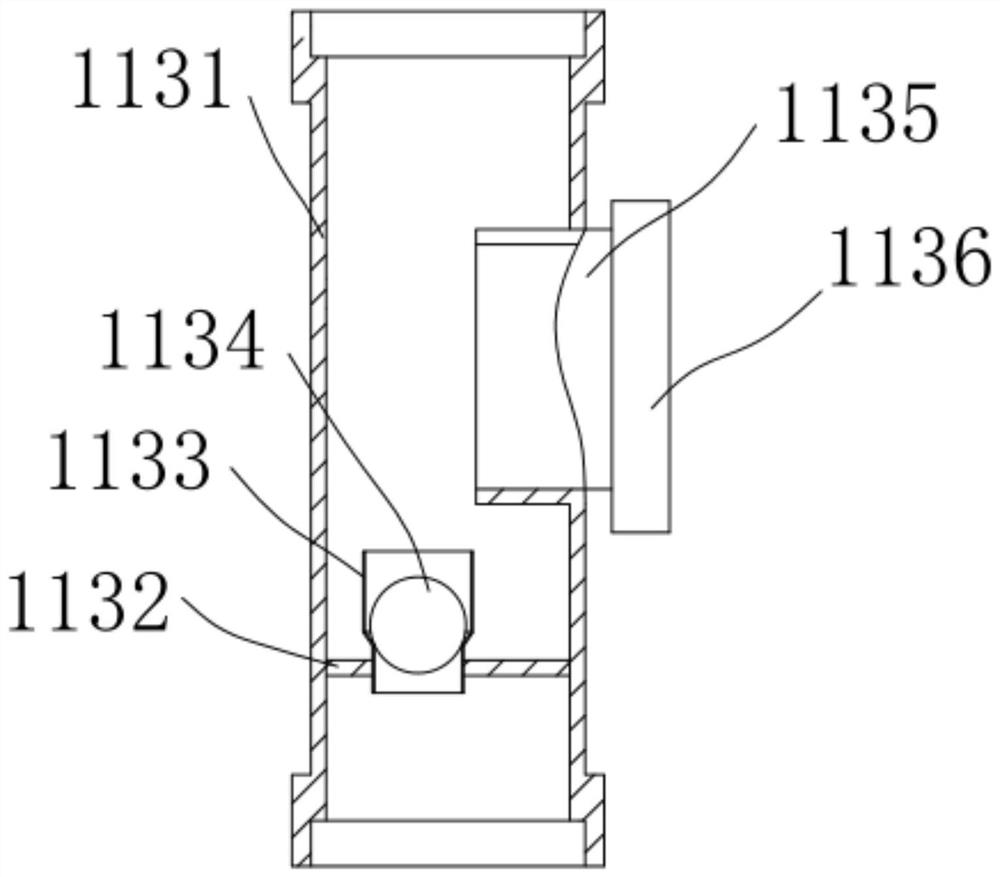

[0038] On the basis of Example 1, as an optional situation, please refer to figure 1 and image 3 , the exhaust assembly 113 includes a connecting pipe 1131 and a side pipe 1135, the connecting pipe 1131 is arranged in the middle of the exhaust pipe 112, the lower part of the connecting pipe 1131 is provided with a baffle 1132, and the middle of the connecting pipe 1131 is provided with an exhaust funnel penetrating through the baffle 1132 1133, a lightweight ball 1134 is movable in the exhaust funnel 1133, a side pipe 1135 is connected to the side wall of the middle part of the connecting pipe 1131, and a sealing cover 1136 is installed on the end of the side pipe 1135 away from the connecting pipe 1131, anaerobic fermentation in the first pool 110 After the generated gas gathers under the baffle plate 1132 of the connecting pipe 1131 to generate positive pressure, the light ball 1134 in the exhaust bucket 1133 is lifted up for exhaust. After the exhaust is completed, the lig...

Embodiment 3

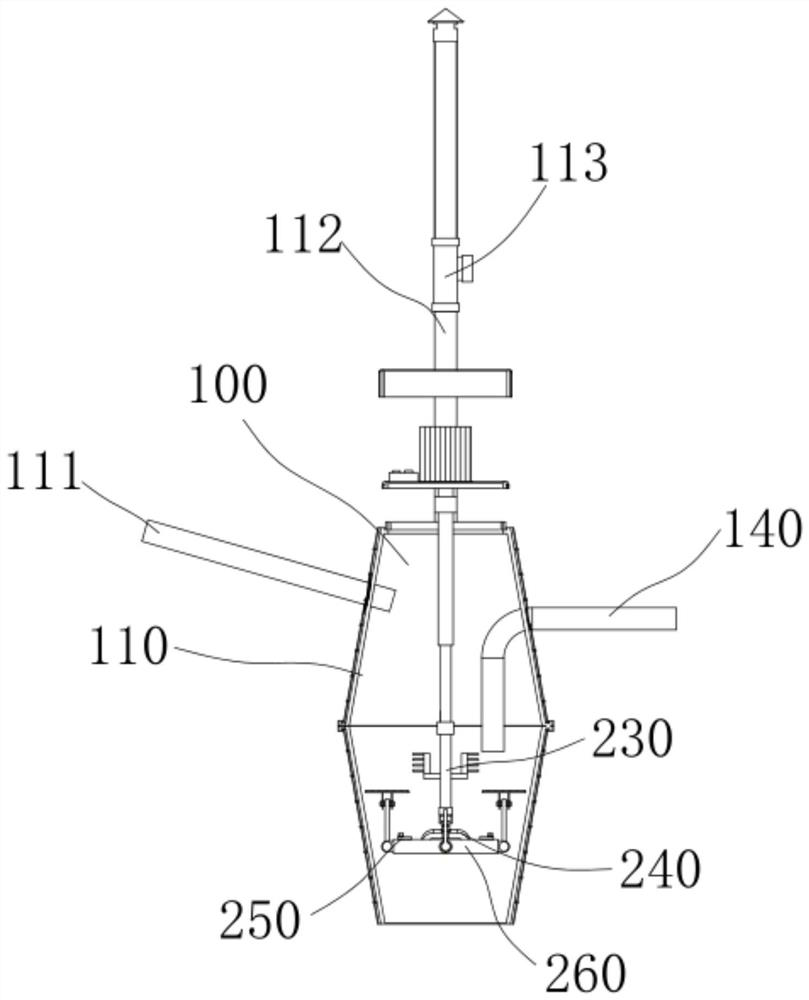

[0040] On the basis of Example 1, as an optional situation, please refer to figure 1 , Figure 7 and Figure 8 , the card shaft 251 is movably connected with the swing frame 260 through the moving plate 250, and the two sides of the lower end of the moving plate 250 are provided with sliders 254. Matching fixing holes 252 are provided on the frame 260 and connected by bolts 253 . A slot 263 is provided on the inner wall of the limiting sleeve 262 , a pivotable rotating cover 273 is provided at the inner end of the limiting shaft 270 , and a strip 274 matching the slot 263 is provided on the outer side of the rotating cover 273 . The moving plate 250 can move along the chute 261 on the swing frame 260 through the slider 254. When the swing frame 260 and the swing arm 240 are connected, the moving plate 250 is moved to the side close to the swing arm 240 in turn, so that the clamping shaft 251 moves to the The ferrule 241 is clipped, and screwed in the bolt 253 in the fixed h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap