Quick-drying and moisture-absorbing type anti-UV knitted fabric

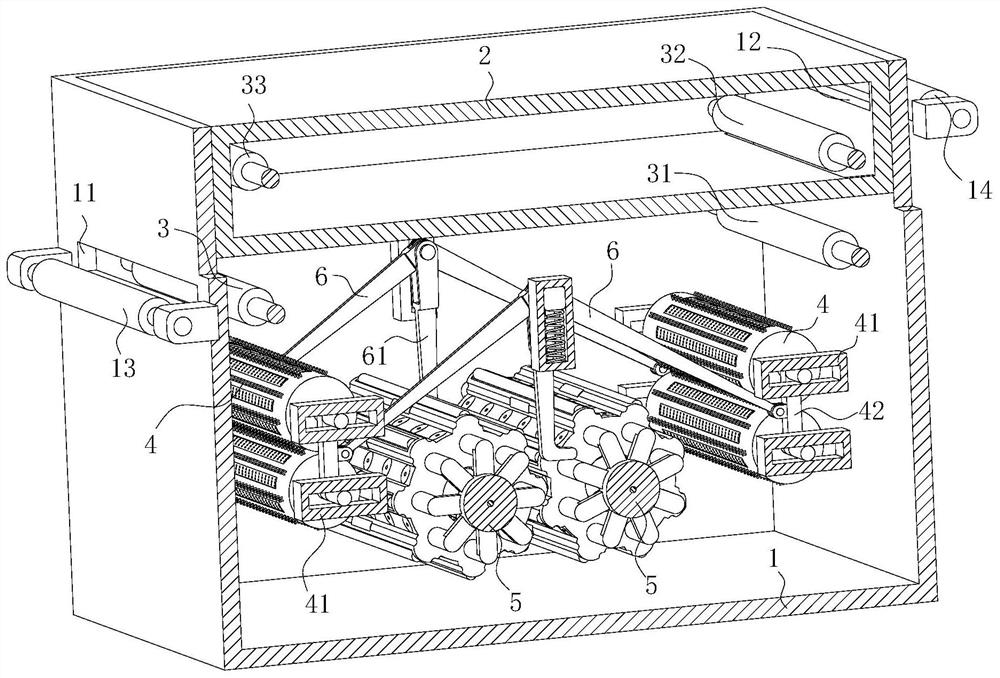

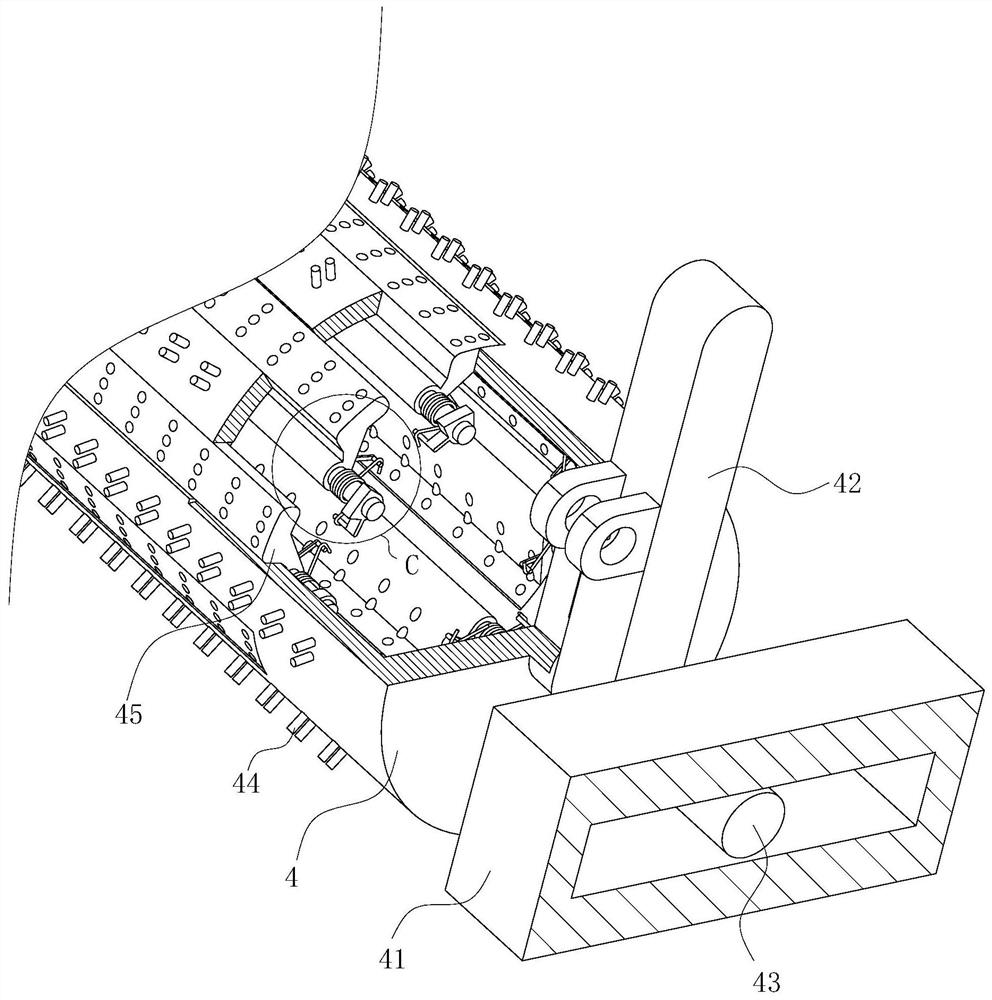

A technology for knitted fabrics and fabrics, which is applied in knitting, weft knitting, warp knitting, etc., which can solve the problems of inability to clean out solid impurities, general cleaning effect, and constant degree of tightness, and achieve stable strength, improved scrubbing effect, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation steps of described lining are as follows:

[0040] S1: Prepare yarn 1 and yarn 2; prepare the acrylic fiber raw material into a cylinder molten liquid, add 10-15wt% nano-titanium dioxide to the acrylic fiber solution, after stirring fully, spray it out through the spinneret to form a mixed acrylic fiber, and then , blending mixed acrylic fiber and polypropylene fiber to obtain yarn 1; preparing a layer solution from viscose fiber raw materials and spandex fiber raw materials, and spraying the mixed solution through a composite fiber spinneret to obtain a composite of viscose fiber and spandex fiber The island-in-the-sea composite fiber, after that, pass the island-in-sea composite fiber through spinning equipment to make yarn two;

[0041] S2: using the yarn 1 and yarn 2 prepared in the step S1 as raw materials to prepare the outer layer and the inner layer through the knitting equipment, and connecting the inner layer and the outer layer through spaced ...

Embodiment approach

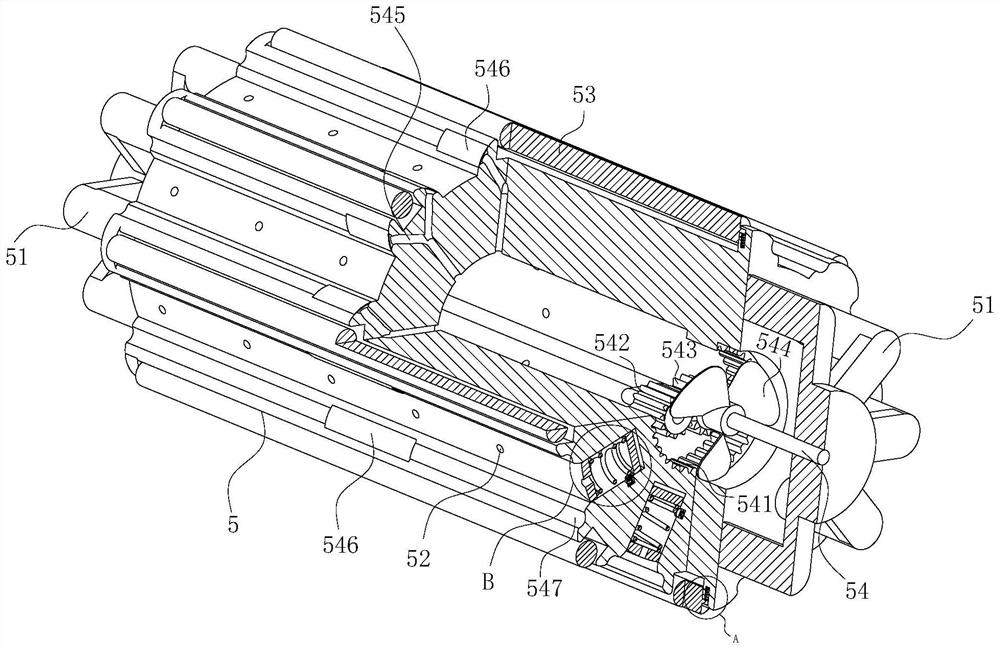

[0045] As an embodiment of the present invention, the protrusion on the stirring roller 5 is provided with an axial installation groove; a roller 53 is installed in the axial installation groove; the roller 53 can be installed in the axial installation groove Free rotation; the end of the axial mounting groove is provided with a vertical mounting groove 533; the vertical mounting groove 533 is distributed along the radial direction of the stirring roller 5; the rotating shaft 3 on the roller shaft 53 is located in the vertical mounting groove 533, and the rotating shaft three can move freely along the vertical mounting groove 533; the spring two 534 is installed in the vertical mounting groove 533; the spring two 534 squeezes the rotating shaft three;

[0046] During work, when the fabric passed through the gap between the two agitating rollers 5, the rollers 53 on the agitating roller 5 were fitted together, and the passing fabric was squeezed to the surface of the agitating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com