Steel slag doped composite foundation structure and construction method thereof

A technology of composite foundation and steel slag, which is applied in the direction of foundation structure engineering, soil protection, sheet pile walls, etc., can solve the problems of over-exploitation, high price, etc., improve utilization rate, reduce sand and gravel mining, and the construction method is simple and convenient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

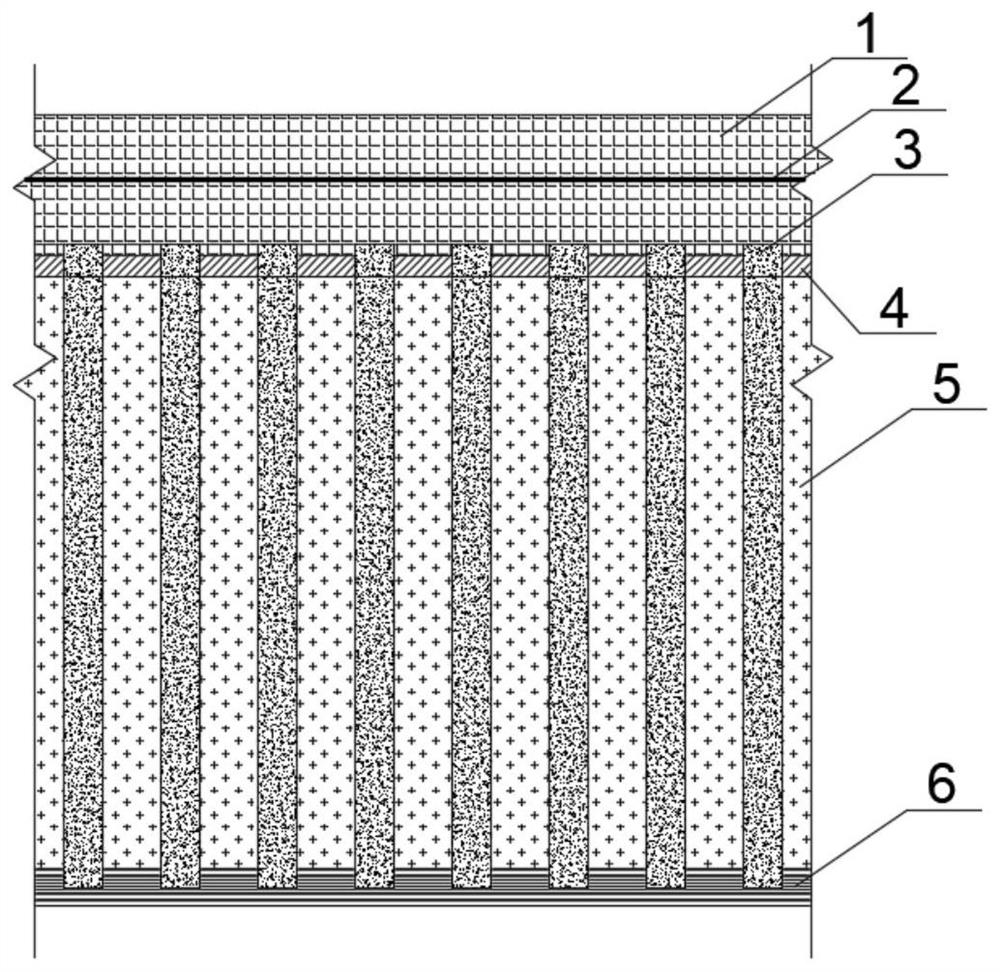

[0032] figure 1 A structural schematic diagram of a composite foundation structure mixed with steel slag according to a preferred embodiment of the present invention is shown. The composite foundation structure includes a gravel sand cushion layer 4 , a steel slag cushion layer 1 and several steel slag concrete piles 3 . refer to figure 1 , The gravel sand cushion layer 4 is laid on the foundation, and the foundation includes a soft soil layer 5 and a bearing layer 6 to enhance the lateral drainage function of the foundation. The steel slag cushion layer 1 is laid on the gravel sand cushion layer 4, and the steel slag cushion layer 1 includes the lower steel slag cushion layer, the geogrid 2 and the upper layer steel slag cushion layer sequentially from bottom to top, and the steel slag cushion layer is laid on the gravel sand cushion layer The cushion layer 1, and the geogrid 2 laid in the steel slag cushion layer 1 can improve the structural strength and rigidity of the fou...

Embodiment 2

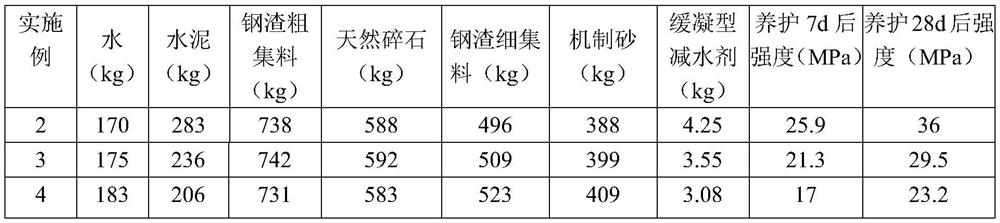

[0034]With reference to the composite foundation structure mixed with steel slag in Example 1, in this embodiment, the raw material components of the steel slag concrete pile 3 and the parts by weight of each component are: 738 parts of steel slag coarse aggregate, 496 parts of steel slag fine aggregate, machine-made sand 388 parts, 588 parts of natural gravel, 283 parts of cement, 170 parts of water, 4.25 parts of retarding superplasticizer, and the volume of steel slag coarse aggregate is the same as that of natural gravel, and the volume of steel slag fine aggregate is the same as that of machine-made sand of the same volume. Among them, the aging time of steel slag coarse aggregate and steel slag fine aggregate is ≥1 year, the particle size of steel slag fine aggregate is ≤4.75mm, the particle size of steel slag coarse aggregate is 5-20mm, and the natural crushed stone is pebble, and the natural The particle size of crushed stone is 5-20mm. The diameter of each steel slag...

Embodiment 3

[0036] With reference to the composite foundation structure mixed with steel slag in Example 1, in this embodiment, the raw material components of the steel slag concrete pile 3 and the parts by weight of each component are: 742 parts of steel slag coarse aggregate, 509 parts of steel slag fine aggregate, machine-made sand 399 parts, 592 parts of natural gravel, 236 parts of cement, 175 parts of water, 3.55 parts of retarding water reducer, and the volume of steel slag coarse aggregate is the same as that of natural gravel, and the volume of steel slag fine aggregate is the same as that of machine-made sand of the same volume. Among them, the aging time of steel slag coarse aggregate and steel slag fine aggregate is ≥1 year, the particle size of steel slag fine aggregate is ≤4.75mm, the particle size of steel slag coarse aggregate is 5-20mm, and the natural crushed stone is pebble, and the natural The particle size of crushed stone is 5-20mm. The diameter of each steel slag c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com