A Drilling Caliper Measurement System Applicable to Working Conditions While Drilling

A technology of borehole caliper measurement and working conditions, which is applied in the directions of measurement, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of shrinking borehole diameter, expanding borehole diameter, and inability to identify cuttings beds, etc., and achieve stable borehole wall , Guarantee the effect of increasing speed and improving efficiency, and ensuring the safety of drilling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

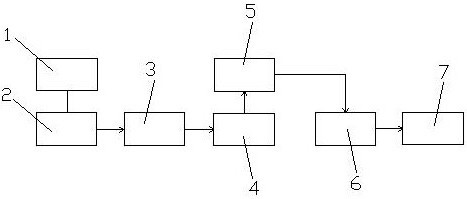

[0033] see figure 1 , a drilling caliper measurement system suitable for working conditions while drilling, including a caliper measurement unit, a downhole data transmission unit and a surface interpretation unit, the caliper measurement unit is installed on the outer wall of the drill collar, and the caliper measurement unit It includes a power supply module 1, a caliper measurement analysis module 2 and an azimuth measurement module 3, the downhole data transmission unit includes a caliper data encoding module 4 and a caliper data transmission module 5, and the ground interpretation unit includes a caliper data decoding module 6 and real-time caliper reconstruction module 7; the caliper data transmission module 5 and the caliper data decoding module 6 carry out signal transmission through the MWD mud pulse, and the caliper measurement and analysis module 2, the azimuth measurement module 3, the caliper data encoding The module 4 and the real-time borehole reconstruction mod...

Embodiment 2

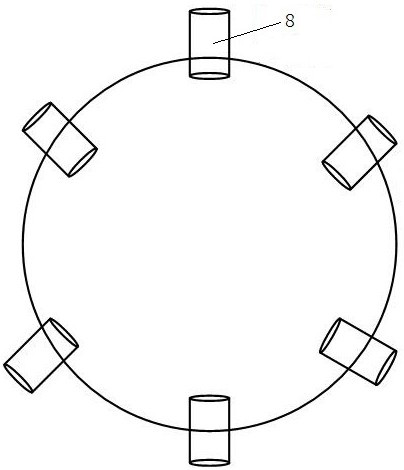

[0036] see Figure 1-Figure 2 , a drilling caliper measurement system suitable for working conditions while drilling, including a caliper measurement unit, a downhole data transmission unit and a surface interpretation unit, the caliper measurement unit is installed on the outer wall of the drill collar, and the caliper measurement unit It includes a power supply module 1, a caliper measurement analysis module 2 and an azimuth measurement module 3, the downhole data transmission unit includes a caliper data encoding module 4 and a caliper data transmission module 5, and the ground interpretation unit includes a caliper data decoding module 6 and real-time caliper reconstruction module 7; the caliper data transmission module 5 and the caliper data decoding module 6 carry out signal transmission through the MWD mud pulse, and the caliper measurement and analysis module 2, the azimuth measurement module 3, the caliper data encoding The module 4 and the real-time borehole reconstruc...

Embodiment 3

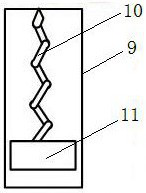

[0039] see Figure 1-Figure 3 , a drilling caliper measurement system suitable for working conditions while drilling, including a caliper measurement unit, a downhole data transmission unit and a surface interpretation unit, the caliper measurement unit is installed on the outer wall of the drill collar, and the caliper measurement unit It includes a power supply module 1, a caliper measurement analysis module 2 and an azimuth measurement module 3, the downhole data transmission unit includes a caliper data encoding module 4 and a caliper data transmission module 5, and the ground interpretation unit includes a caliper data decoding module 6 and real-time caliper reconstruction module 7; the caliper data transmission module 5 and the caliper data decoding module 6 carry out signal transmission through the MWD mud pulse, and the caliper measurement and analysis module 2, the azimuth measurement module 3, the caliper data encoding The module 4 and the real-time borehole reconstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com