Wet type drilling rotary mechanism

A rotary mechanism, wet technology, used in mechanical equipment, earthwork drilling, drilling equipment, etc., can solve the problems of poor sealing effect, unusable, difficult maintenance, etc., to achieve simple and fast maintenance, improved service life, and good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

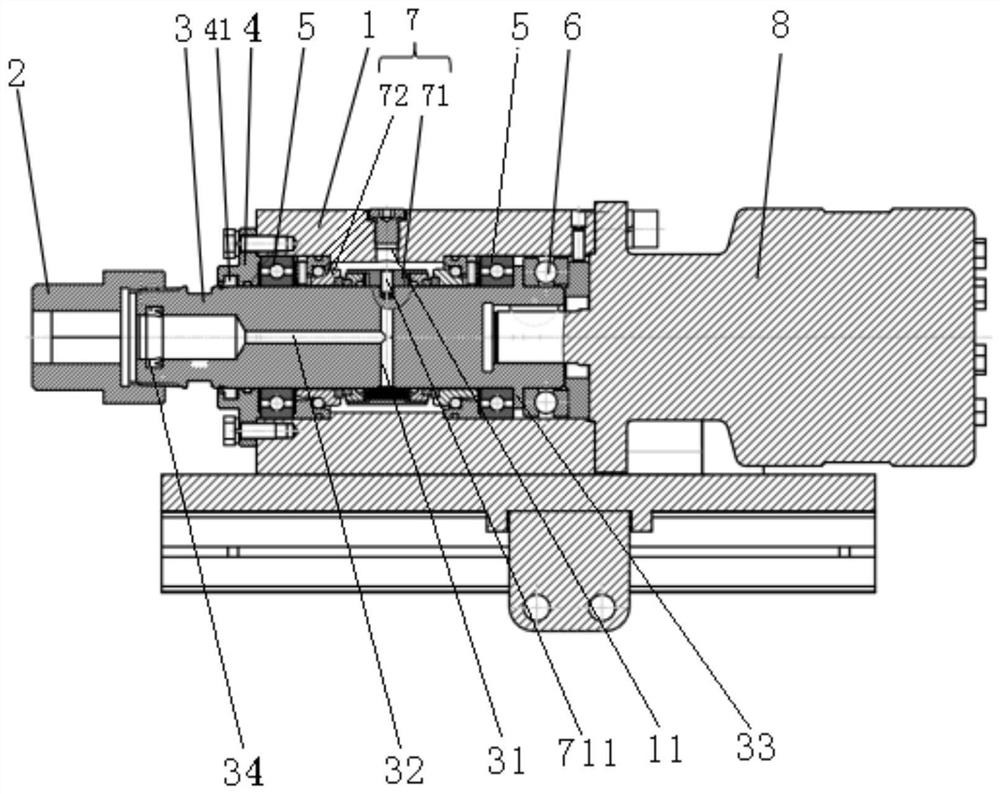

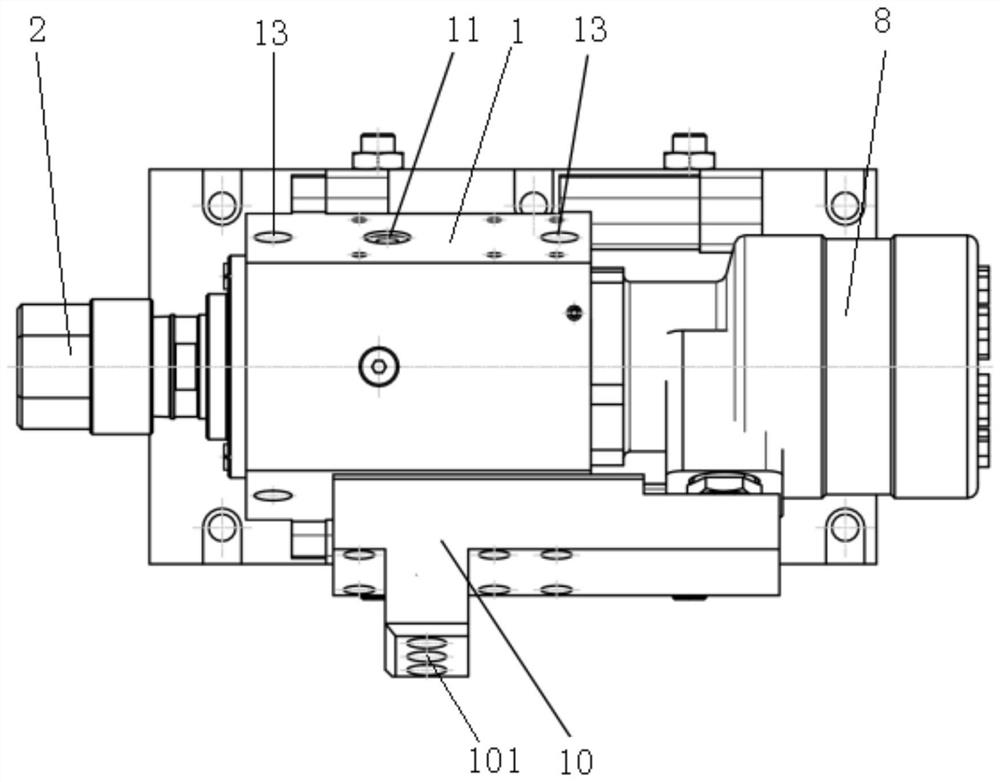

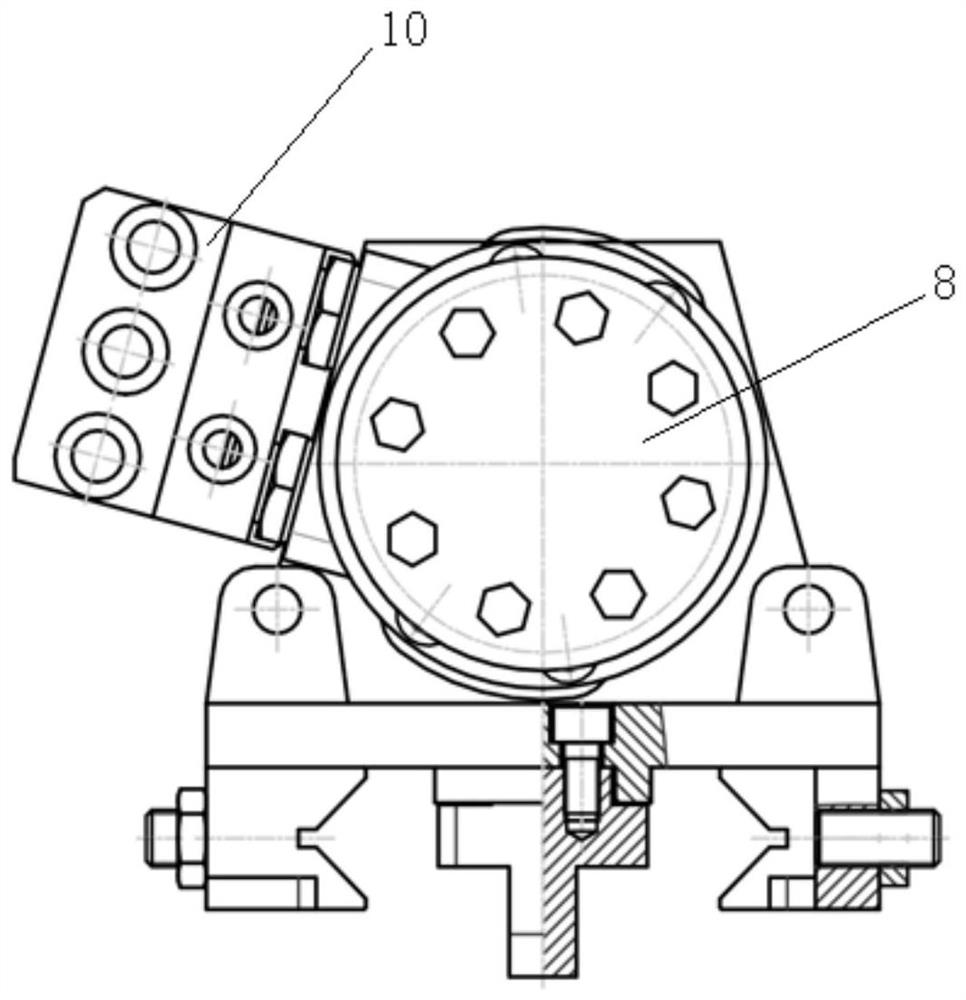

[0021] In order to solve the slewing mechanism of the existing bolter and wet dust removal bolt and cable drilling rig, the existing accessories are not easy to replace during maintenance, the surface precision of the slewing shaft is high during processing, and the casing is corroded after water leakage, resulting in scrap or short service life. etc., the present application provides a JCJM-ZZZX type wet drilling rotary mechanism. Its specific example is as follows.

[0022] Refer to attached Figures 1 to 3 As shown, the wet drilling rotary mechanism of this embodiment includes a casing 1 and a rotary shaft 3 passing through the central through hole of the casing 1. One end of the rotary shaft 3 is connected to the power motor 8 through a spline, and the other end is connected to the shaft nut. 2 connections. The power motor 8 drives the rotary shaft 3 to rotate like this, and the rotary shaft 3 drives the spindle nut 2 to rotate, finally drives the drill rod to rotate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com