Portable shear span section local electrochemical accelerated corrosion device and steel beam corrosion system

A corrosion-accelerating, electrochemical technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., to ensure tight closure, good airtightness, and easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

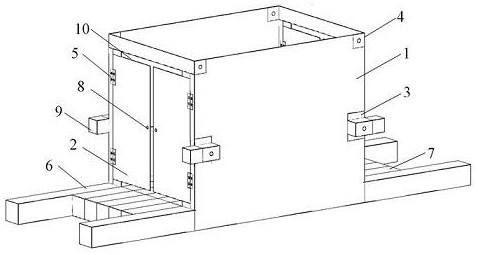

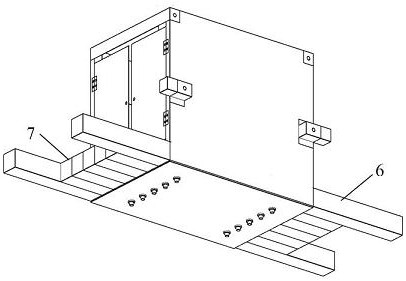

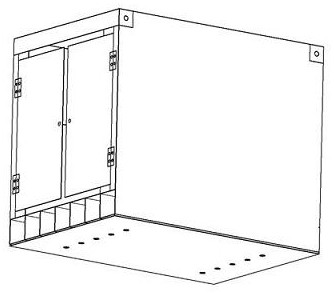

[0033] The specific embodiment of the present invention is as figure 1 and Figure 6 shown.

[0034] In this embodiment, a portable electrochemical accelerated corrosion device for the shear span section, such as figure 1 and figure 2 As shown, the device is a rectangular corrosion tank 1, comprising a plastic tank frame, a short plastic block 7 and a long plastic strip 6, such as image 3 shown. The plastic trough frame is a U-shaped structure composed of three faces; the middle face of the plastic trough frame is placed on the horizontal plane, and the two opposite vertical faces are the trough frame wall plates; the front and rear two trough frame wall plates The upper part of the room is installed and fixed by the cross baffle 4, such as Figure 5 Shown; the bottom of the plastic tank frame is a double-layer composite bottom, such as image 3 As shown; the double-layer composite bottom is provided with two first rectangular grooves parallel to each other and a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com