Separation device and separation system for pulverized coal gasification

A technology of separation device and pulverized coal, which is applied in the direction of swirl device and the device whose axial direction of swirl can be reversed, etc. It can solve the problems of unstable flow field inside the cyclone separator, escape of fine particles, and low separation efficiency. Achieve the effects of avoiding back-mixing and short-circuit flow, high carbon conversion rate, and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

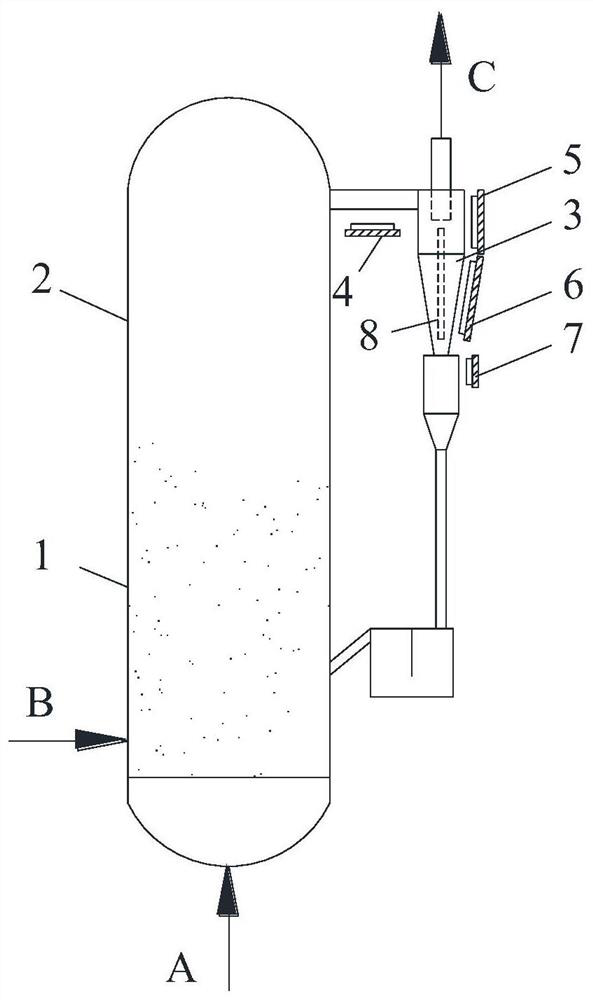

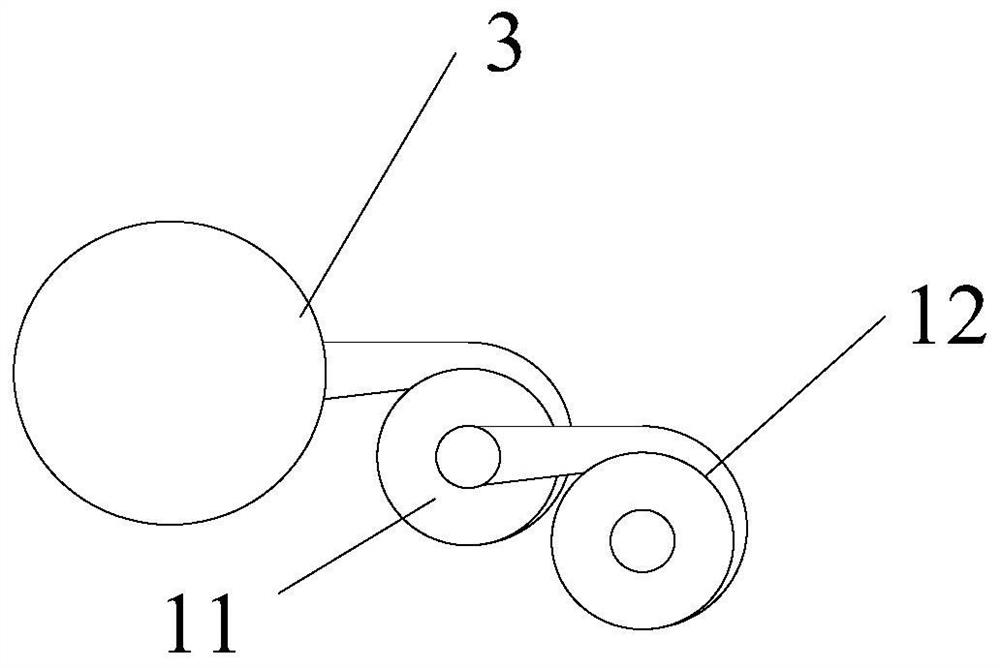

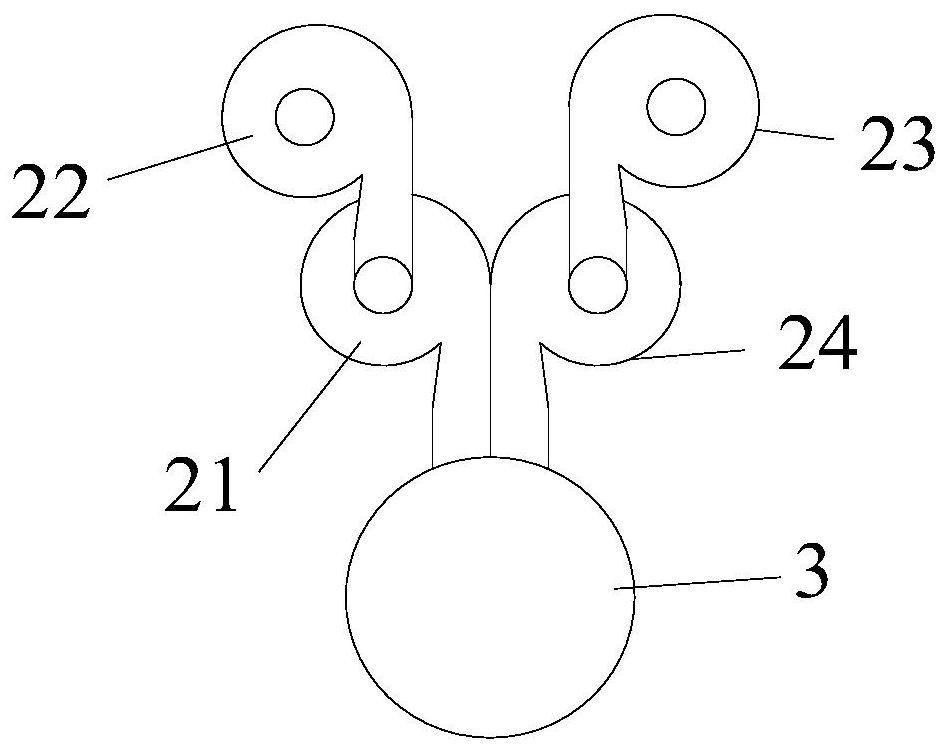

[0036] The separation process is as follows: the fine ash and incompletely reacted carbon-containing particles reacted in the fluidized bed reactor enter the cyclone separator through the settling section together with the crude gas; the fine ash and incompletely reacted carbon-containing particles are separated in the cyclone In the pipeline in front of the inlet of the cyclone, after the sound waves in the sound field of the cyclone inlet speaker are reunited, larger particle clusters are formed and enter the cyclone separator for separation; The ring-shaped separation space, the tapered separation space and the ash hopper are gradually reunited and then separated in the process of sound wave radiation transmitted by the ring-shaped separation space speaker, the cone-shaped separation space speaker, and the speaker at the upper end of the ash hopper.

[0037] Inner Mongolia lignite was used in the experiment, and it was crushed to a size below 3mm to obtain pulverized coal. ...

Embodiment 2

[0039] The separation process is as follows: the fine ash and incompletely reacted carbon-containing particles reacted in the fluidized bed reactor enter the cyclone separator through the settling section together with the crude gas; the fine ash and incompletely reacted carbon-containing particles are separated in the cyclone In the pipeline in front of the inlet of the cyclone, after the sound waves in the sound field of the cyclone inlet speaker are reunited, larger particle clusters are formed and enter the cyclone separator for separation; The ring-shaped separation space, the tapered separation space and the ash hopper are gradually reunited and then separated in the process of sound wave radiation transmitted by the ring-shaped separation space speaker, the cone-shaped separation space speaker, and the speaker at the upper end of the ash hopper.

[0040] Inner Mongolia lignite was used in the experiment, and it was crushed to a size below 3mm to obtain pulverized coal. ...

Embodiment 3

[0042] The separation process is as follows: the fine ash and incompletely reacted carbon-containing particles reacted in the fluidized bed reactor enter the cyclone separator through the settling section together with the crude gas; the fine ash and incompletely reacted carbon-containing particles are separated in the cyclone In the pipeline in front of the inlet of the cyclone, after the sound waves in the sound field of the cyclone inlet speaker are reunited, larger particle clusters are formed and enter the cyclone separator for separation; The ring-shaped separation space, the tapered separation space and the ash hopper are gradually reunited and then separated in the process of sound wave radiation transmitted by the ring-shaped separation space speaker, the cone-shaped separation space speaker, and the speaker at the upper end of the ash hopper.

[0043] Inner Mongolia lignite was used in the experiment, and it was crushed to a size below 3mm to obtain pulverized coal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com