Automatic saw for processing wood processing leftover triangular materials

A technology for processing residues and triangles, which is applied to wood processing equipment, circular saws, manufacturing tools, etc., can solve the problems of low production efficiency and high labor intensity, and achieve the effect of high labor intensity and stable processing dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

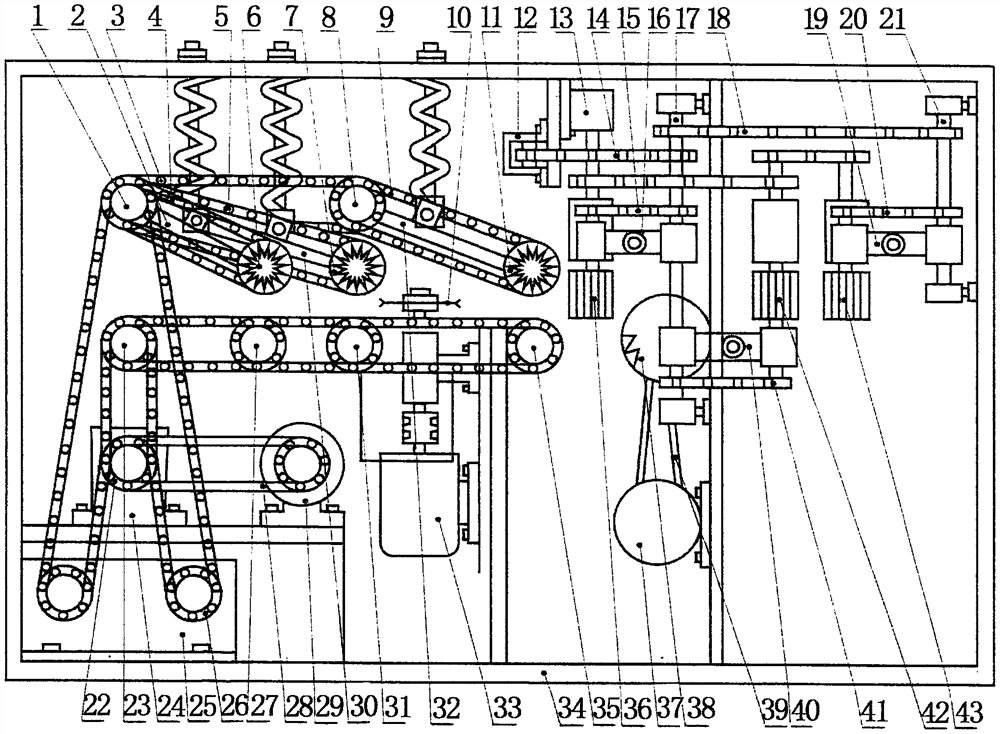

[0014] Cross-cutting motor 33 drives cross-cutting saw blade 10 to rotate, and vertical cutting motor 37 drives vertical cutting saw blade 38 to rotate by V-belt 39, and feed motor 29 drives speed reducer 24 by V-belt 28, and speed reducer drives medium by sprocket chain 22 Axle 23, the intermediate wheel shaft drives the first fixed feeding wheel shaft 27 through the sprocket chain, the first fixed feeding wheel shaft drives the second fixed feeding wheel shaft 31 through the sprocket chain, and the second fixed feeding wheel shaft drives the third fixed feeding wheel shaft through the sprocket chain. The feed wheel shaft 35 is fixed, and the two ends of the first, second, third, and fourth pendulum shafts are respectively linked with the frame 34 bearings and bearing blocks. The reducer drives the first pendulum shaft 1 through the chain 26 and the first reverse wheel mechanism 25, the first pendulum shaft drives the second pendulum shaft 8 through the sprocket chain 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com