Light-emitting automobile sign convenient for millimeter-wave radar penetration and manufacturing method thereof

A millimeter wave radar and car signage technology, applied in the field of auto parts, can solve the problems of high price, low melting point of indium, and very strict production process requirements, and achieve the effect of reducing production cost, improving qualification rate and good lighting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

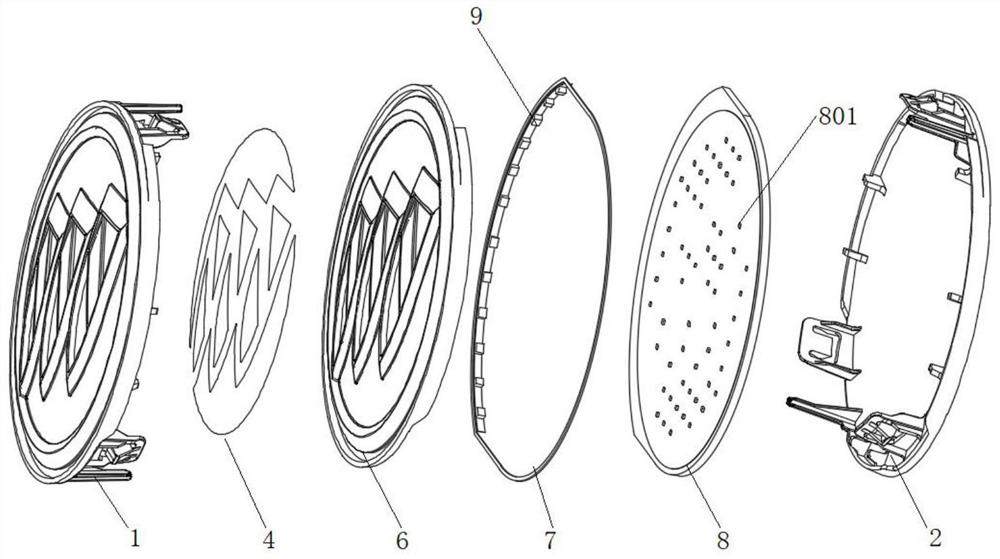

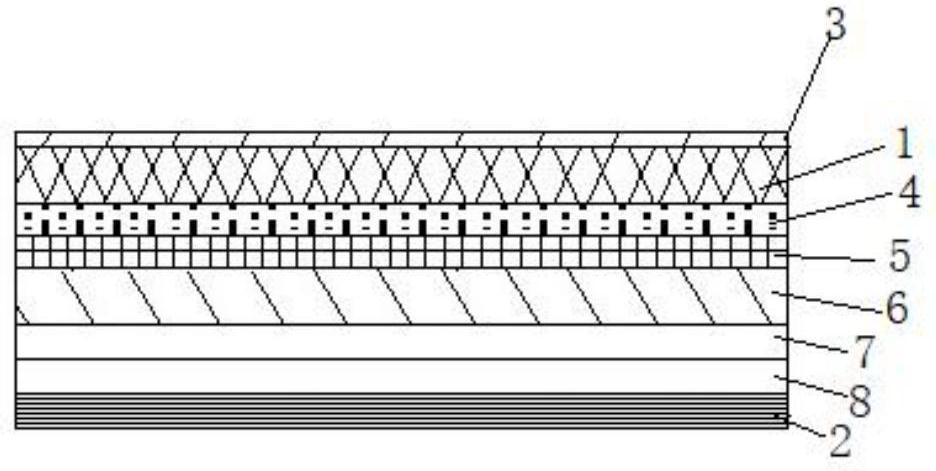

[0033] A light-emitting car sign that facilitates the penetration of millimeter-wave radar, comprising a sign body 1 and a sign base 2, the back of the sign body 1 and the sign base 2 are connected by sticking or vibration friction welding;

[0034] The front of the sign body 1 is sprayed with a UV high-hardness topcoat layer 3, and the back of the sign body 1 is provided with a silk screen ink layer 4, a UV primer layer 5, and a nano-inorganic silicon coating 6 in sequence.

[0035] Wherein, the total thickness of the screen printing ink layer 4, the UV primer layer 5 and the nano-inorganic silicon coating 6 is 20-30 μm, and the thickness of the nano-inorganic silicon coating 6 is 0.2-0.5 μm.

[0036] In this embodiment, the sign body 1 and the silk screen ink layer 4 in the light-emitting car sign that facilitates the penetration of the millimeter-wave radar provide an identification for distinguishing the car sign, wherein the sign body 1 is a transparent sign made of transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com