Edge cutting equipment for blown film

A technology of blown film and blown film, which is applied in the field of machinery, can solve the problems of aggravated film surface density, tensile damage, reduced packaging efficiency of mechanical blown film trimming, and affecting the unqualified rate of film cutting of batch products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

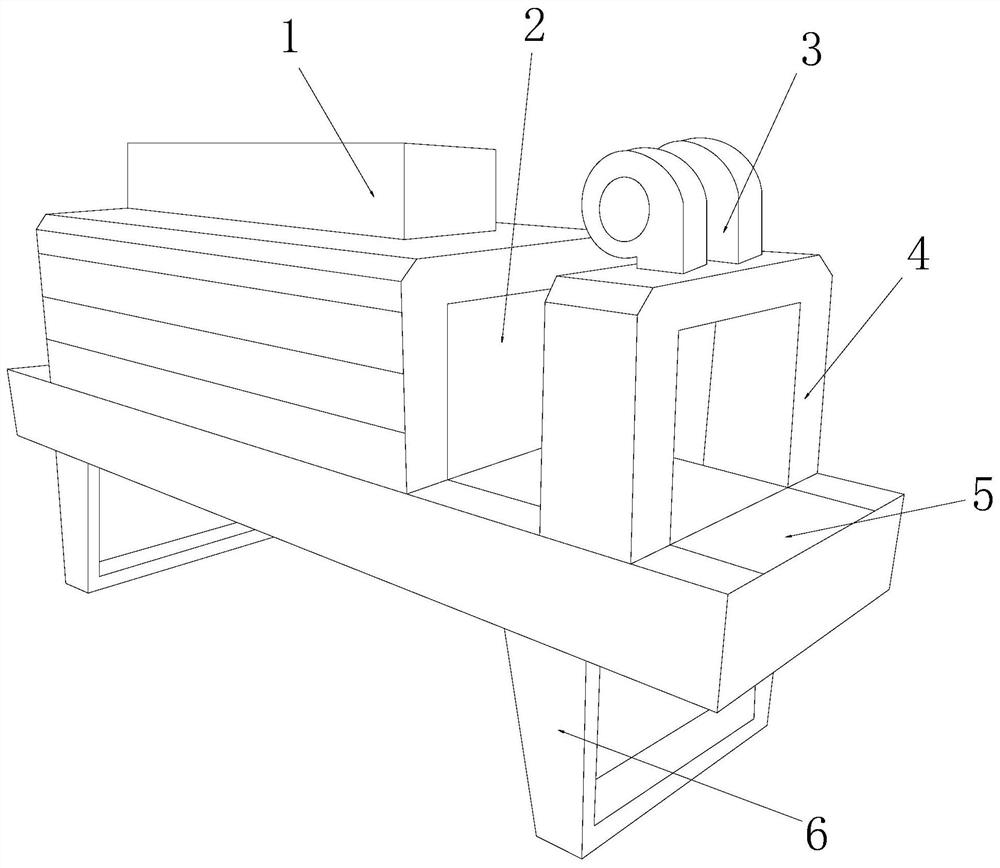

[0032] see Figure 1-Figure 6 , the present invention provides a blown film edge trimming equipment, its structure includes: electric control box 1, packaging tank 2, blower 3, blown film cutting door frame 4, conveyor belt table 5, bracket frame tripod 6, the blowing The plastic film cutting door frame 4 is nested under the bottom of the blower 3 and is on the same vertical plane. The blown film cutting door frame 4 is installed on the upper right corner of the conveyor belt platform 5. The support frame tripod 6 is provided with two and Welded on the left and right lower corners of the conveyor belt platform 5 respectively, the electric control box 1 is installed on the top of the packaging horizontal tank 2, and the packaging horizontal tank 2 is nested on the top of the conveyor belt platform 5, and the packaging horizontal tank 2 passes through the conveyor belt The table 5 is mechanically connected with the blown film cutting door frame 4, the blown film cutting door fra...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a blown film trimming equipment, other aspects are the same as embodiment 1, the difference is:

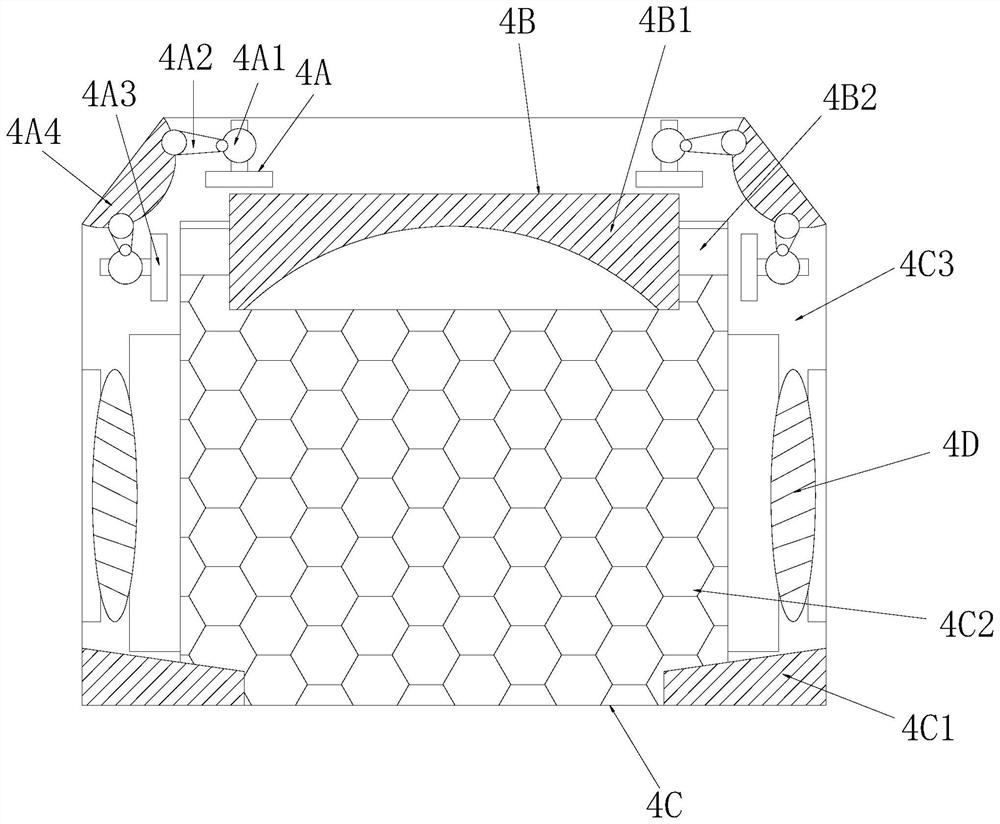

[0040] see figure 2 , the grid door frame 4C is composed of a trapezoidal column seat 4C1, a honeycomb grid 4C2, and a door frame groove 4C3. The honeycomb mesh 4C2 is embedded in the door frame groove 4C3 and is on the same vertical plane, and the honeycomb mesh 4C2 covers the door frame groove 4C3 to form an anti-crack film during blow molding.

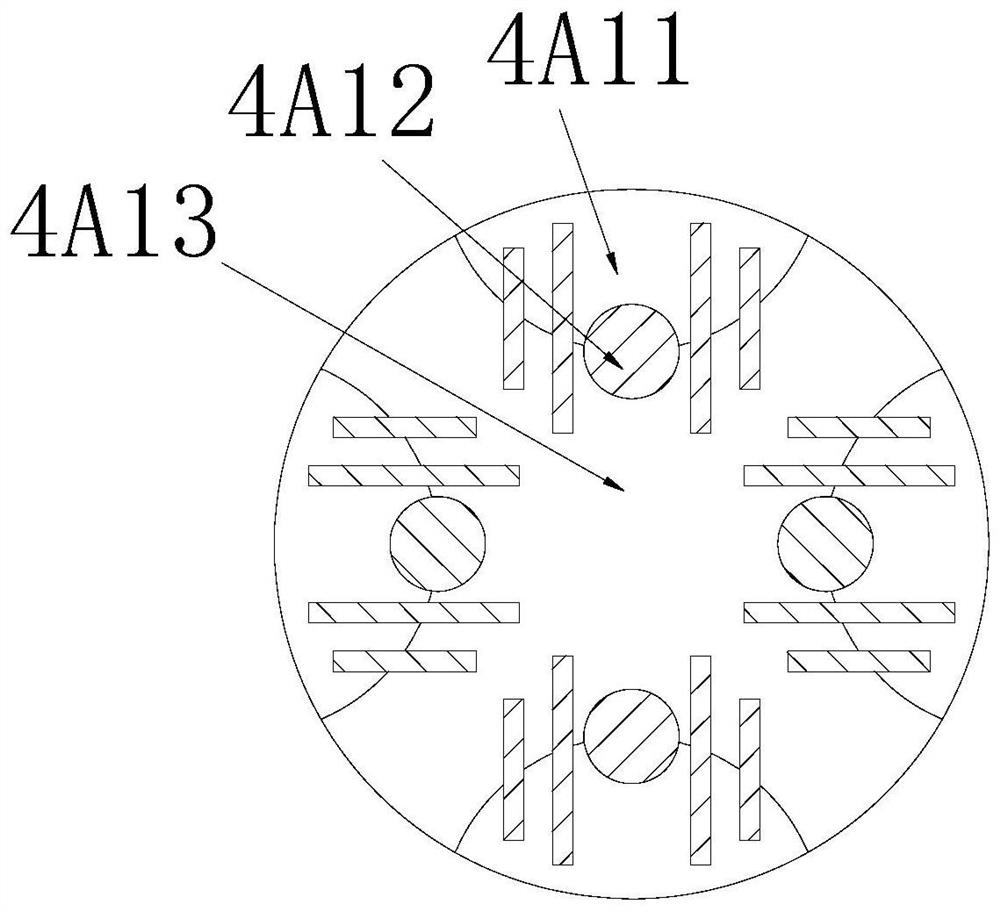

[0041] see Figure 6 The trapezoidal column pad 4C1 is composed of a rubber column block 4C11, a truss spring plate 4C12, and a trapezoidal column groove 4C13. The rubber column block 4C11 is installed directly above the truss spring plate 4C12, and the truss spring plate 4C12 is inserted into the The inside of the trapezoidal column groove 4C13 is on the same vertical plane. The trapezoidal column groove 4C13 is a column groove structure with a narrow left side and a wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com