Grease wastewater treatment equipment

A wastewater treatment and equipment technology, applied in the direction of grease/oily substance/suspton removal devices, liquid separation, chemical instruments and methods, etc., can solve the problems of effective removal, impossibility, high viscosity, etc., to achieve convenient cleaning operation and reduce impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

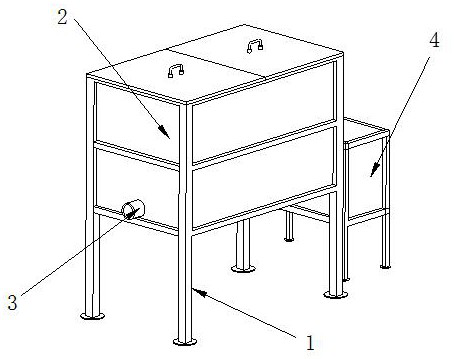

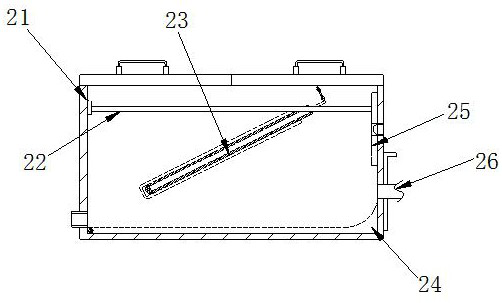

[0026] see Figure 1-Figure 6 , the specific embodiment of the present invention is as follows: a kind of grease wastewater treatment equipment, its structure comprises support 1, body 2, oil outlet 3, water storage tank 4, described support 1 top surface and body 2 bottom surfaces are welded and connected, and described discharge The outer ring of the oil port 3 is connected to the left side of the body 2, and the left side of the water storage tank 4 is connected to the right side of the body 2; , a scraper 25, a liquid pumping tube 26, the inside of the housing 21 is fixedly connected to both ends of the guide rail 22, the front of the threaded ejector rod 23 is fixedly installed on the back of the housing 21, and the left side of the storage platform 24 is embedded in the right side of the housing 21 , the top of the scraper 25 is transitionally connected to the outer ring of the guide rail 22, the outer ring of the suction pipe 26 is connected to the right side of the hou...

Embodiment 2

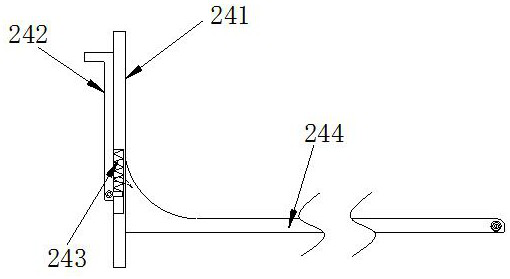

[0033] see Figure 7-Figure 8 The specific embodiment of the present invention is as follows: the scraper 25 includes a block 251, a track hole 252, a top groove 253, and a scraper 254, the front of the block 251 and the track hole 252 are integrally formed, and the block 251 The center and the top groove 253 are integrally formed, the outer layer of the scraper 254 is fixedly installed on the bottom of the block 251, and the top groove 253 is a smooth hemispherical groove structure.

[0034] Wherein, the scraper 254 includes a fixed sleeve C1, a spring C2, an anti-backward plate C3, an anti-backward stick C4, and a scraper head C5. The interior of the fixed sleeve C1 is welded to one side of the anti-backward plate C3, and the fixed sleeve C1 The inside is connected to the anti-retreat stick C4 through the spring C2, the top surface of the scraper head C5 is fixedly installed on the bottom surface of the anti-retreat stick C4, and the anti-retreat plate C3 is provided with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com