Natural gas filter

A technology of natural gas and filter, which is applied in the direction of gas fuel, petroleum industry, fuel, etc. It can solve the problems of short passage path, insufficient water filtration, pipeline leakage, etc., and achieve the effect of sufficient filtration, increased contact time and reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

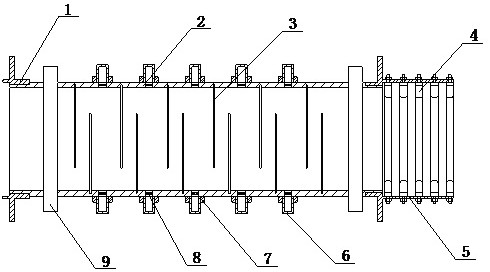

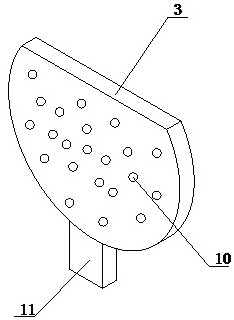

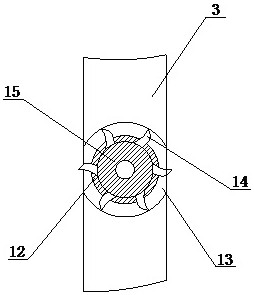

[0016] A natural gas filter of the present invention is achieved as follows: a natural gas filter of the present invention consists of a flange (1), a filter cartridge (2), a baffle (3), a heating pipe (4), and a fastening screw (5 ), water-absorbing cylinder (6), fastening nut (7), mesh cover (8), sealing valve (9), moisture-absorbing hole (10), fixed block (11), moisture-absorbing cotton (12), ball cavity (13), guide vane (14) and rotating ball (15), the two ends of the filter cartridge (2) are respectively fixed with flanges (1), the heating cylinder and one of the flanges (1) Fixed connection, a plurality of equidistantly distributed heating tubes (4) are arranged in the heating cylinder, the two ends of the heating tubes (4) are respectively fixedly connected with the heating cylinder by screws, two sets of baffles (3) are placed in the filter Inside the cylinder (2), two sets of baffles (3) are respectively placed on the bottom and top of the filter cylinder (2), and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com