Double-heating seamless underwear fabric and manufacturing method

A technology of seamless underwear and a manufacturing method, which is applied in the field of textile fabrics and can solve problems such as poor thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

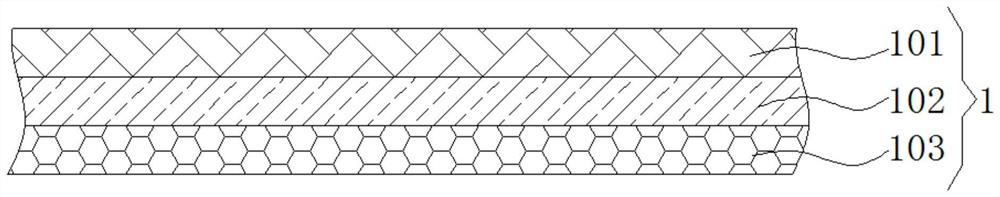

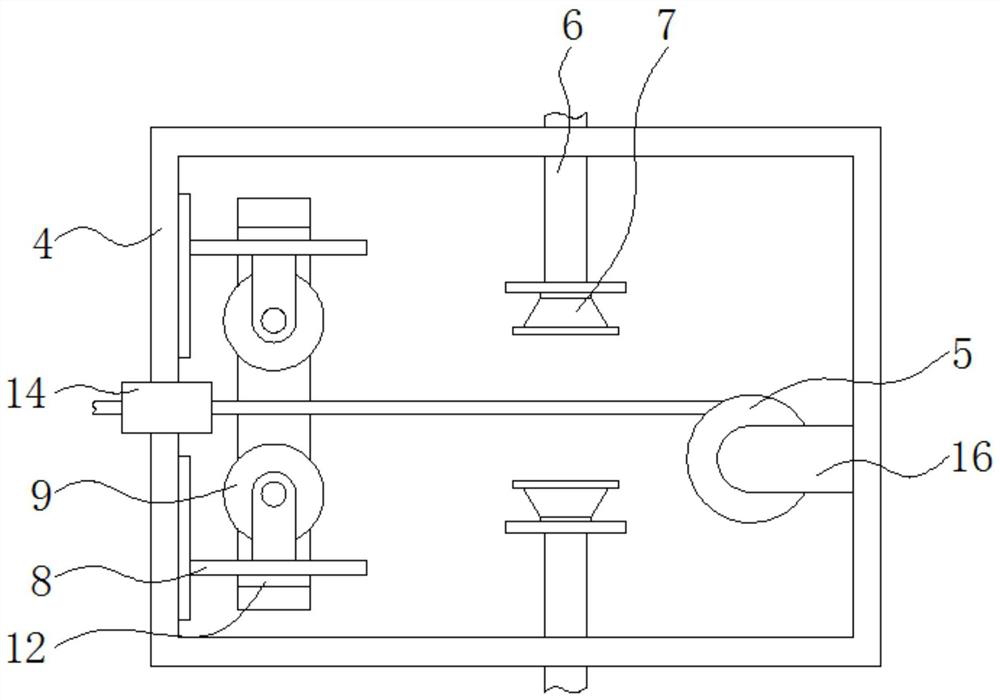

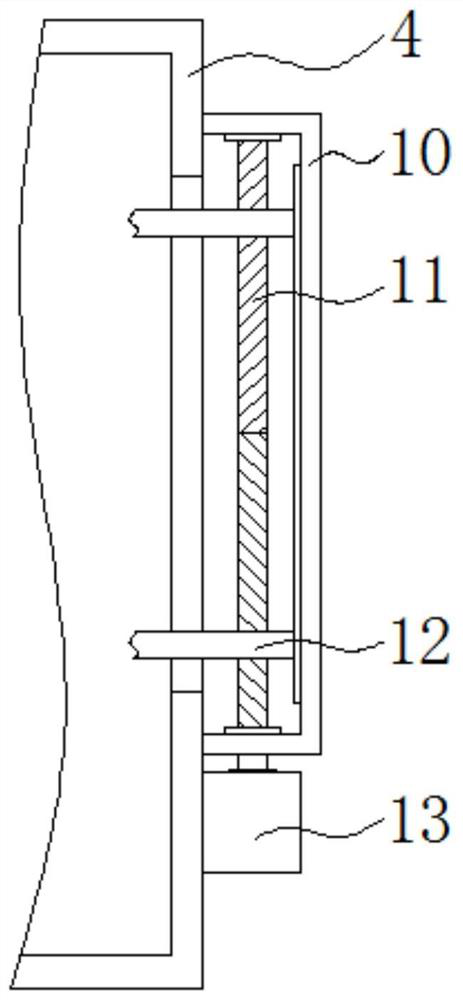

[0036] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 Schematic diagram of the structure of the first embodiment of the double-heating seamless underwear fabric and the manufacturing method provided by the present invention; figure 2 Schematic diagram of the structure of the drying device provided by the present invention; image 3 for figure 2 A side view of the housing shown; Figure 4 for figure 2 The schematic diagram of the structure of the winding roller shown; Figure 5 for figure 2 The top view of the second U-shaped groove shown. The double heating seamless underwear fabric includes: fabric body 1;

[0037] The fabric body 1 includes a surface layer 101 , an intermediate layer 102 is disposed at the bottom of the surface layer 101 , and an inner layer 103 is disposed at the bottom of the intermediate layer 102 .

[0038] The fabric body 1 is composed of 46.3% acrylic fiber, 31.2% regenerated cellulose fiber, 18....

no. 2 example

[0067] Please refer to Figure 6 , based on the double heating seamless underwear fabric provided in the first embodiment of the present application, the second embodiment of the present application proposes another double heating seamless underwear fabric. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0068] Specifically, the difference between the double-heating seamless underwear fabric provided by the second embodiment of the present application is that it also includes a skin-friendly layer 2 and an adsorption layer 3, the skin-friendly layer 2 is made of silk fiber material, The adsorption layer 3 is made of activated carbon fiber material.

[0069] Silk fiber material is a kind of natural protein fiber. It is the lightest, softest and thinnest natural fiber in nature. It is rich in 18 kinds of amino acids needed by the huma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com