Sand-washing blockage-removing steam injection tool

A technology for sand flushing and steam injection, which is applied in the direction of flushing wellbore, production fluid, wellbore/well components, etc. It can solve the problems of oil pipe thread wear, reduce steam injection effect, and fail to turn pumping in time, and achieve steam injection channel big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

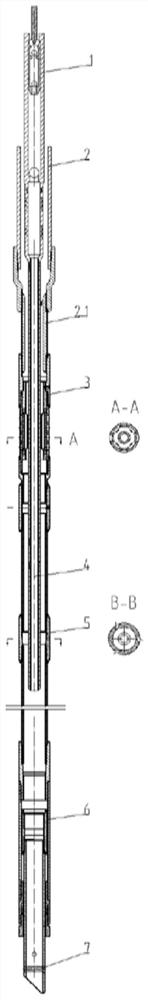

[0048] Such as Figure 1-21As shown in the figure, a steam injection tool for sand washing and blocking removal is provided with a supporting oil well pump 1, a steam injection outer pipe 2, a bridge-type sand washing single flow valve 3, a sand washing core pipe 4, and a swirl sand washing machine from top to bottom. Tube 5, heat-expandable telescopic tube 6, anti-drop oblique tip 7;

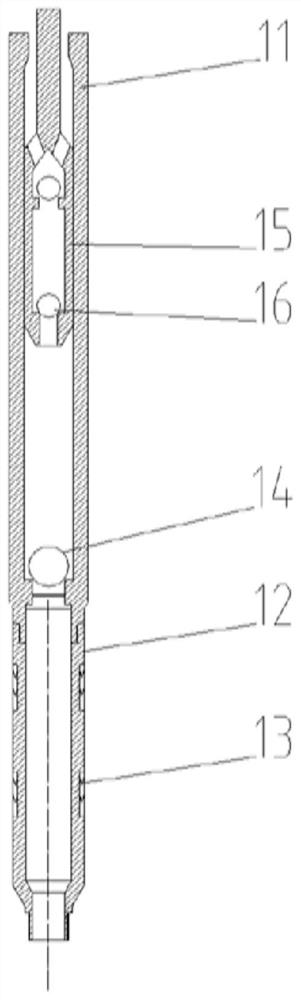

[0049] Such as figure 2 As shown, the supporting oil pump 1 is provided with a pump barrel 11, a plunger 12, a floating valve ball 13, a fixed valve ball 14, a sealing mandrel 15, and a first sealing cup 16 from top to bottom;

[0050] Such as image 3 As shown, the steam injection outer pipe 2 is sequentially provided with a conversion joint 21, a first outer pipe 22, and a reducing bush 23 from top to bottom;

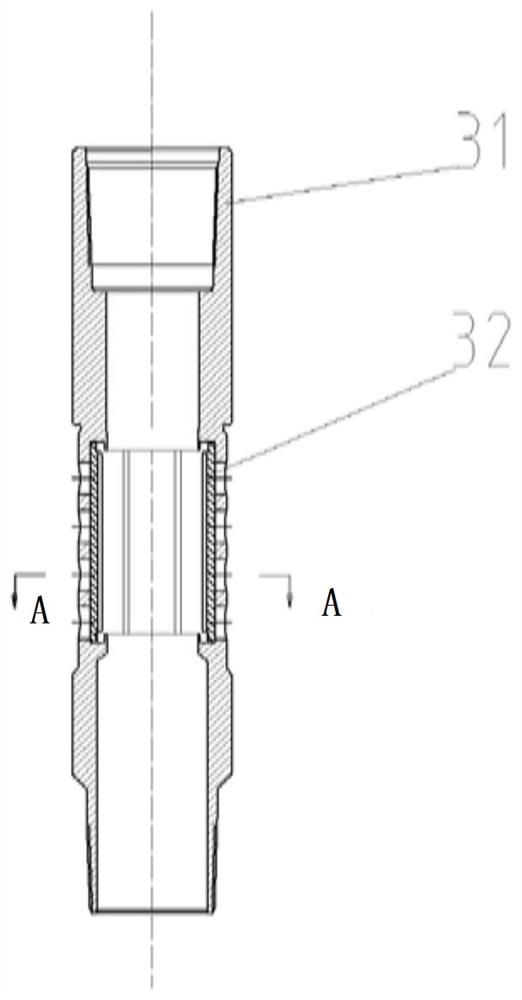

[0051] Such as Figure 4 As shown, the bridge-type sand washing check valve 3 is provided with a housing 31 and a valve plate 32 sequentially from top to bottom;

[0052] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com