Air inlet terminal and vacuum pump provided with air inlet terminal

A terminal and air intake channel technology, applied in the field of automobile brake control, can solve the problems of high rubber sphericity requirement, poor vacuum performance of vacuum pump, high opening pressure of air intake terminal, etc. High performance, optimized preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

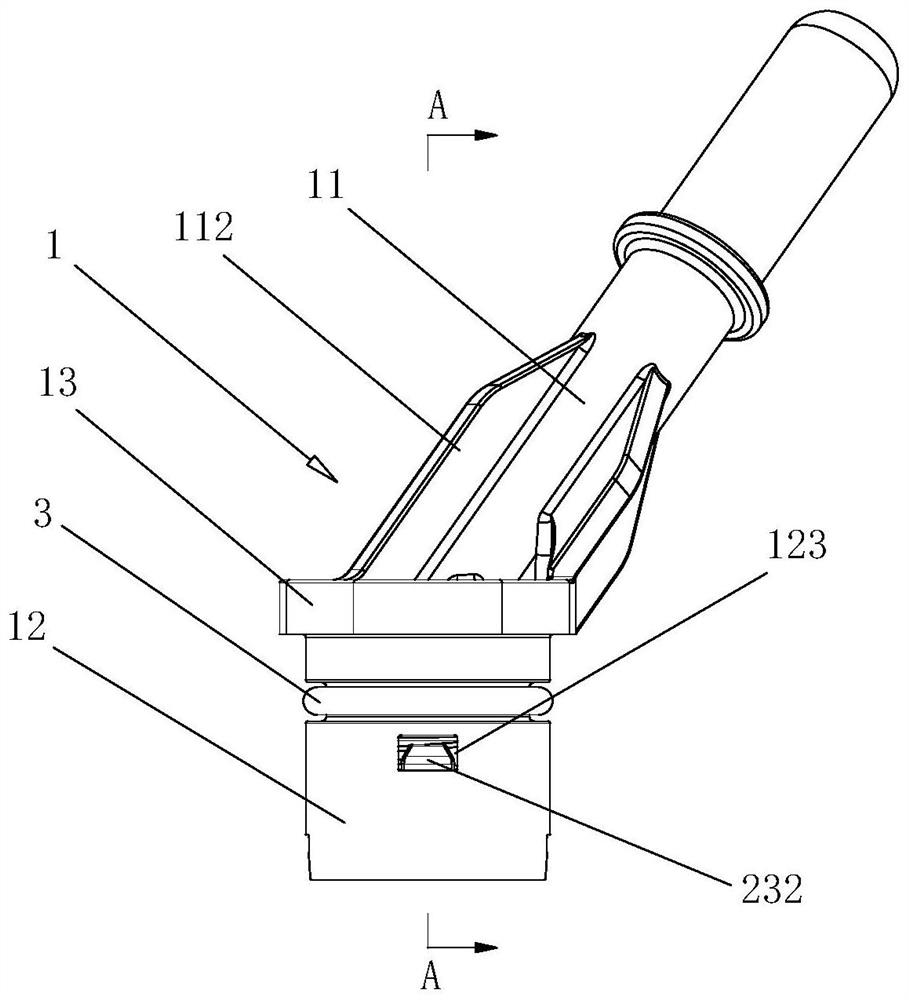

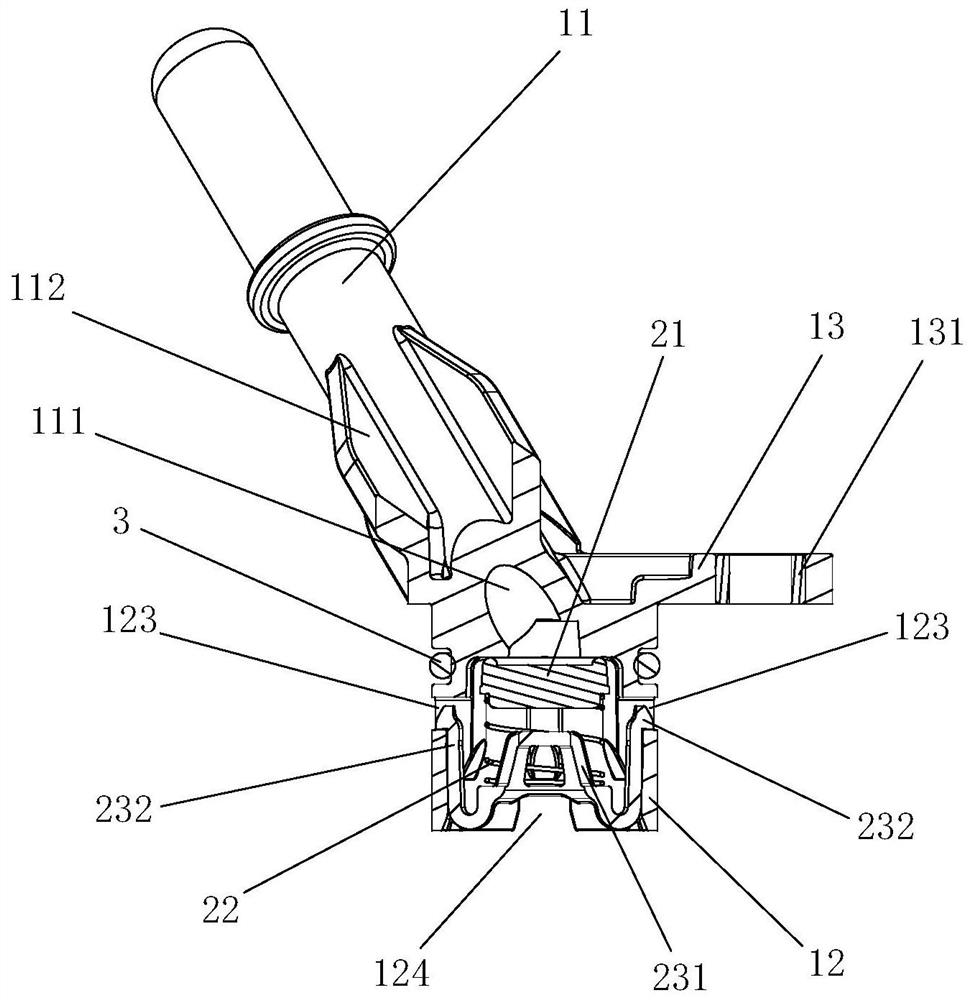

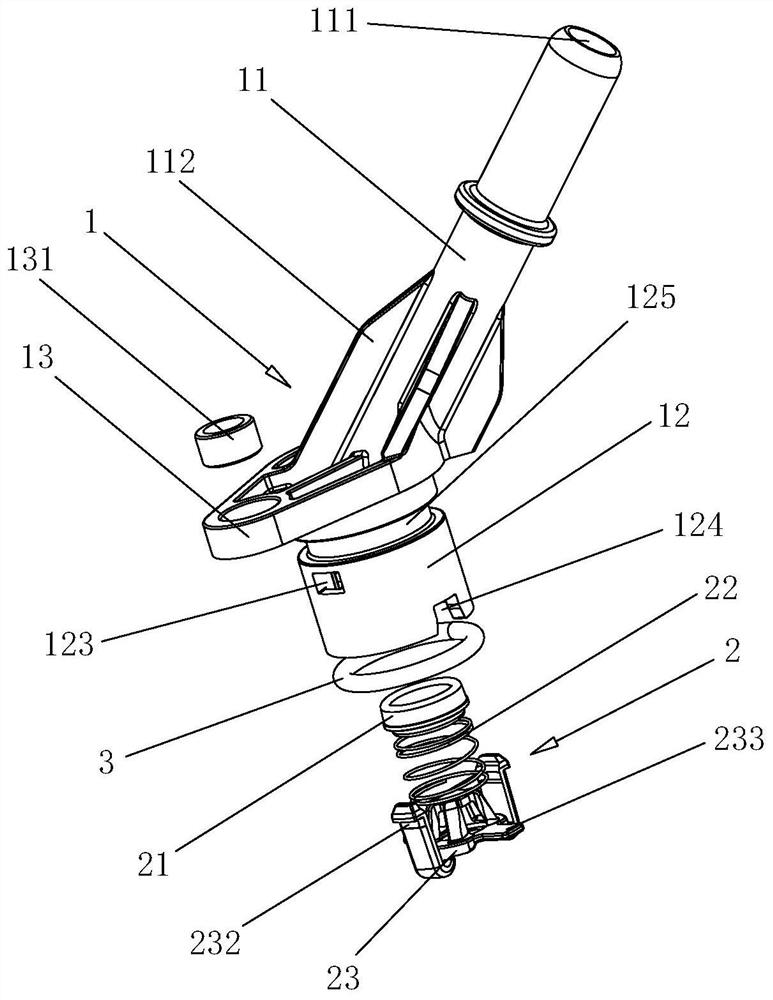

[0037] Embodiment 1, combining Figure 1 to Figure 6 , an air intake terminal, including a terminal housing 1 and a spring seal assembly 2, the terminal housing 1 includes an upper housing 11 and a lower housing 12, the lower housing 12 is located below the upper housing 11, and its upper end and The lower end of the upper casing 11 is integrally formed. The outer contour of the lower housing 12 is cylindrical and arranged vertically. The upper housing 11 is a rod-shaped structure and is arranged obliquely to one side relative to the lower housing 12. The upper housing 11 has an air intake passage 111 inside, The inside of the lower housing 12 is a circular cavity, the air intake channel 111 can communicate with the circular cavity, and the upper end of the air intake channel 111 communicates with the booster.

[0038] The connection between the lower end of the upper shell 11 and the lower shell 12 has a connecting portion 13 extending laterally to the other side, the connec...

Embodiment 2

[0047] Example 2, combined with Figure 7 , a vacuum pump, comprising a pump casing 4, the inside of the pump casing 4 has an air flow channel, the port of the air flow channel is configured with the air intake terminal described in Embodiment 1, the lower housing 12 extends to the inside of the port of the air flow channel, and the connecting part 13 is detachably fixedly connected with the pump housing 4 through the screws 5 located in the steel nesting 131. The lower casing 12 is matched with the inner wall of the port through the sealing ring 3, the circular cavity communicates with the air flow channel, and the sealing ring 3 can better ensure the sealing between the lower casing 12 and the pump housing 4 sex.

[0048] According to the operating conditions of the intake terminal, that is, the air pressure (maximum 1 bar) coming from the chamber of the booster and the volume of the chamber, the aperture size of the intake terminal can be calculated. According to the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com