Method for setting boundary constraint distance value of boundary constraint spraying track planning

A technology of boundary constraints and setting methods, applied in constraint-based CAD, spraying devices, design optimization/simulation, etc., can solve the problems of overspraying at workpiece boundaries, waste of paint, and low spraying efficiency, and achieve the improvement of paint utilization, The effect of improving spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A method for setting a boundary constraint distance value for boundary constraint spraying trajectory planning, comprising the following steps:

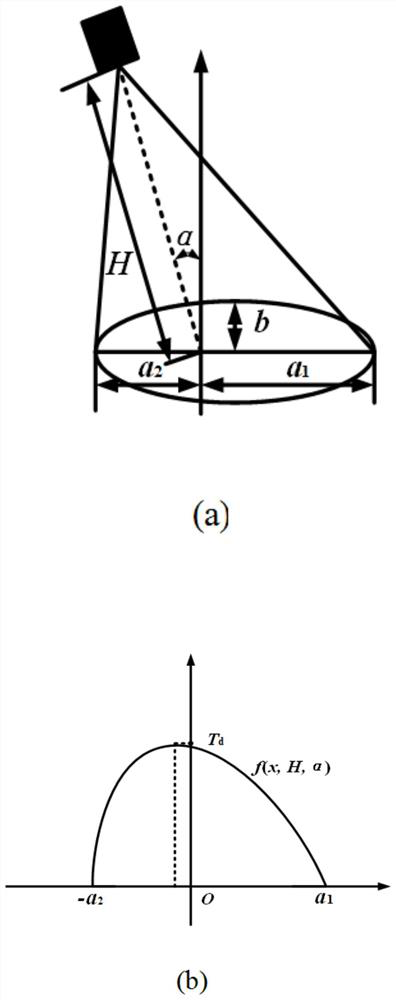

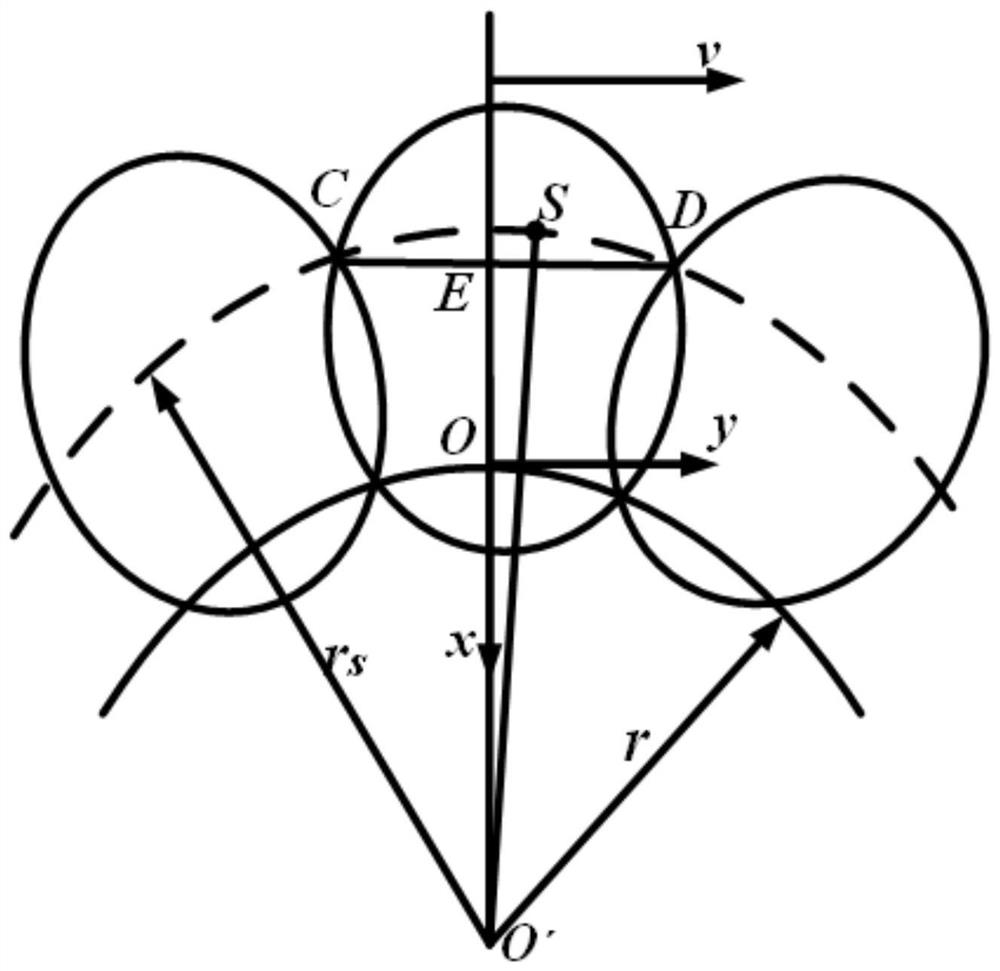

[0051] Step 1, based on the established static spraying model of the spray gun with variable position and posture, construct a dynamic spraying model of the spray gun along the arc path, and the spatial shape of the spray torch of the spray gun is a cone;

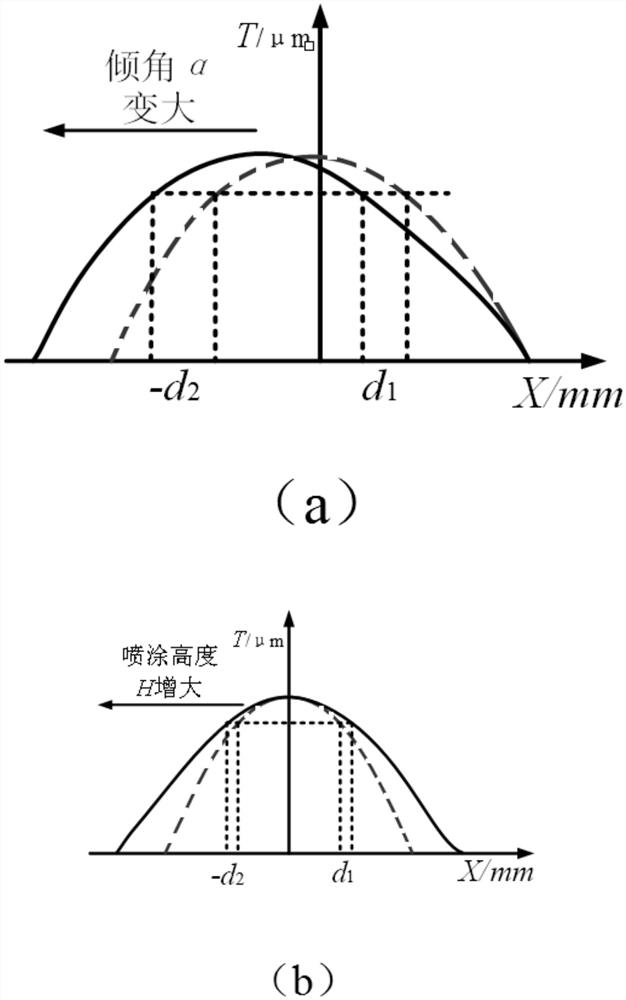

[0052] Step 2, based on the requirement that the workpiece boundary meets the allowable minimum coating thickness, the boundary constraint distance is defined, and the influence laws of the boundary curve curvature radius, spraying height and spraying angle on the boundary constraint distance are respectively clarified;

[0053] Step 3, according to the shape of the boundary curve on the surface of the workpiece to be sprayed, set a uniform boundary constraint distance value to ensure that the quality of the coating film thickness at the boundary meets the requirements at each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com