Beet strip tilling and deep fertilization all-in-one machine

A deep fertilization and all-in-one machine technology, which is applied to agricultural machinery and tools, shovels, plows, etc., can solve the problems of increased consumption of manpower, material and financial resources, low fertilizer utilization rate, and sand and dust, so as to improve fertilizer utilization rate and save energy. The effect of eliminating work links and saving work costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

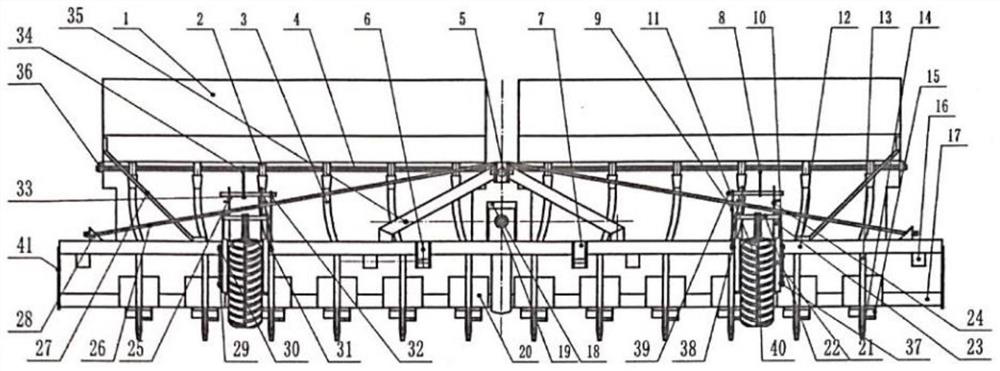

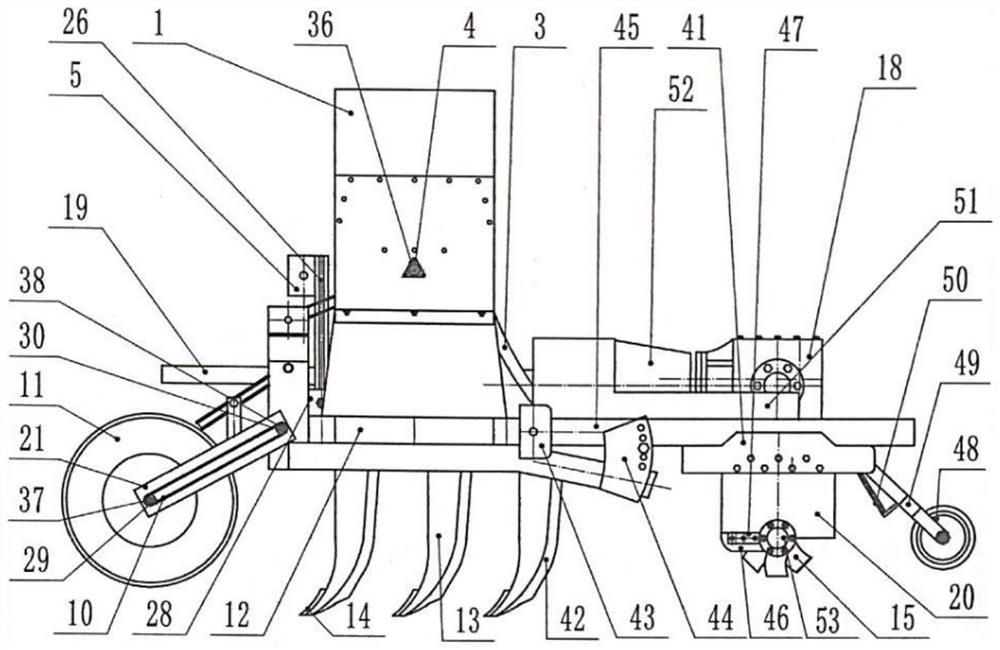

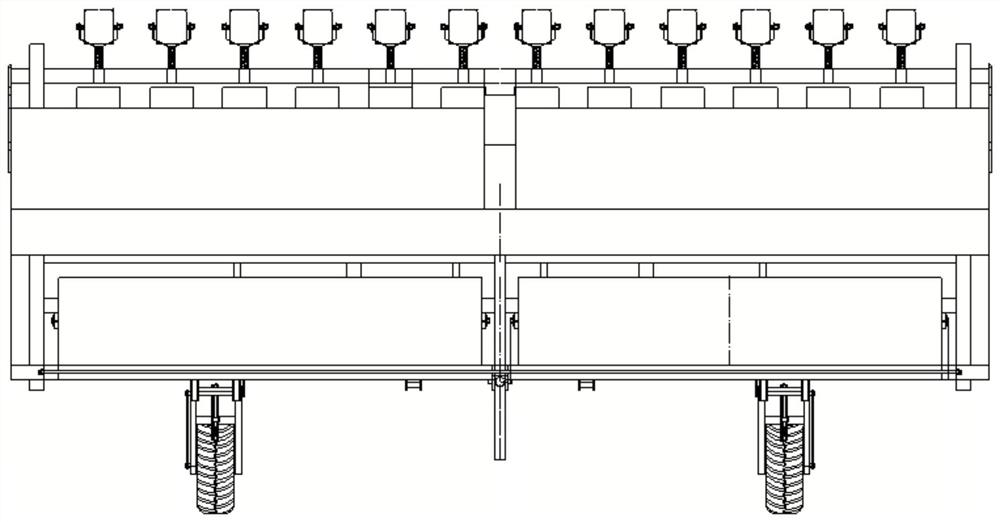

[0027] Specific implementation mode one: see Figure 1-2 This embodiment will be described. The all-in-one machine for cultivating and fertilizing sugar beet strips described in this embodiment includes a number of fertilization boxes 1, a number of fertilizer discharge boxes 2, a number of fertilizer discharge pipes 3, a fertilization driving hexagonal shaft 4, two fertilizer discharge drives and depth-limiting wheels 11, Front frame 12, some subsoiling and fertilizing plow posts 13, subsoiling shovels 14, some rotary cultivating knives 15, rotary tilling shaft 17, transmission box 18, soil retaining shield 20, fertilization pipe 42, rear frame 45 and suppression wheel 48,

[0028] Some fertilization boxes 1 are installed above the front frame 12, some subsoiling fertilization plow posts 13 are installed below, and fertilizer discharge drives and depth-limiting wheels 11 are respectively installed on both sides of the front. Fertilizer box 2, each fertilizer discharge box 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com