A kind of sweet blueberry wine and its brewing process

A blueberry wine and sweet technology, applied in the field of fruit wine brewing, can solve the problems of affecting taste, high acidity, high price, etc., and achieve the effects of increasing anthocyanin content, increasing nutritional value, and improving the degree of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

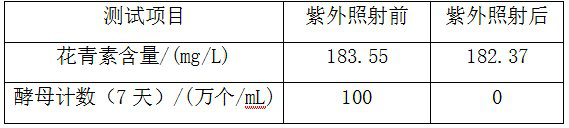

Image

Examples

Embodiment 1

[0057] A brewing process of sweet blueberry wine, comprising the steps of:

[0058] (1) Raw material pretreatment: select fresh blueberries that are intact and free of mildew and rinse them;

[0059] (2) Freezing: Freeze the fresh blueberry fruit rinsed in step (1) at -14°C to obtain blueberry frozen fruit;

[0060] (3) The first adjustment of sugar content: Take 30Kg of frozen blueberry fruit, thaw naturally at room temperature, then crush the thawed blueberry fruit, add 150g of rock sugar during the crushing process for the first sugar adjustment, and stir Uniformly, the skin dregs impregnating liquid is obtained, and the skin dregs impregnating liquid is placed at room temperature and then added to the fermentation equipment;

[0061] (4) Add pectinase: take 30ml of skin dregs soaking solution prepared in step (3), add 0.5g of pectinase, stir evenly, and add to the fermentation equipment;

[0062] (5) The second adjustment of sugar content and adding yeast: add 1g of whit...

Embodiment 2

[0076] A brewing process of sweet blueberry wine, comprising the steps of:

[0077] (1) Raw material pretreatment: select fresh blueberries that are intact and free of mildew and rinse them;

[0078] (2) Freezing: Freeze the fresh blueberry fruit rinsed in step (1) at -15°C to obtain frozen blueberry fruit;

[0079] (3) The first adjustment of sugar content: take 40Kg of frozen blueberry fruit, thaw naturally at room temperature, then crush the thawed blueberry fruit, add 180g of rock sugar during the crushing process for the first sugar content adjustment, and stir Uniformly, the skin dregs impregnating liquid is obtained, and the skin dregs impregnating liquid is placed at room temperature and then added to the fermentation equipment;

[0080] (4) Add pectinase: take 40ml of skin dregs soaking solution prepared in step (3), add 0.8g of pectinase, stir evenly, and add to the fermentation equipment;

[0081] (5) The second adjustment of sugar content and adding yeast: add 1....

Embodiment 3

[0095] A brewing process of sweet blueberry wine, comprising the steps of:

[0096] (1) Raw material pretreatment: select fresh blueberries that are intact and free of mildew and rinse them;

[0097] (2) Freezing: Freeze the fresh blueberry fruit washed in step (1) at -16°C to obtain blueberry frozen fruit;

[0098] (3) The first adjustment of sugar content: Take 50Kg of frozen blueberry fruit, thaw naturally at room temperature, then crush the thawed blueberry fruit, add 200g of rock sugar during the crushing process for the first sugar content adjustment, and stir Uniformly, the skin dregs impregnating liquid is obtained, and the skin dregs impregnating liquid is placed at room temperature and then added to the fermentation equipment;

[0099] (4) Adding pectinase: take 50ml of skin dregs soaking solution prepared in step (3), add 1g of pectinase, stir evenly, and add to the fermentation equipment;

[0100] (5) The second adjustment of sugar content and adding yeast: add 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com