Ice cream production method and ice cream machine

A production method and ice cream machine technology, applied in frozen sweets, food science, applications, etc., can solve the problems of uneven ice crystal effect, large volume and weight, and low efficiency of ice cream, and achieve enhanced sound pressure and average sound energy density , Improve heat and mass transfer efficiency, increase the effect of freezing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the examples, but the embodiments of the present invention are not limited thereto.

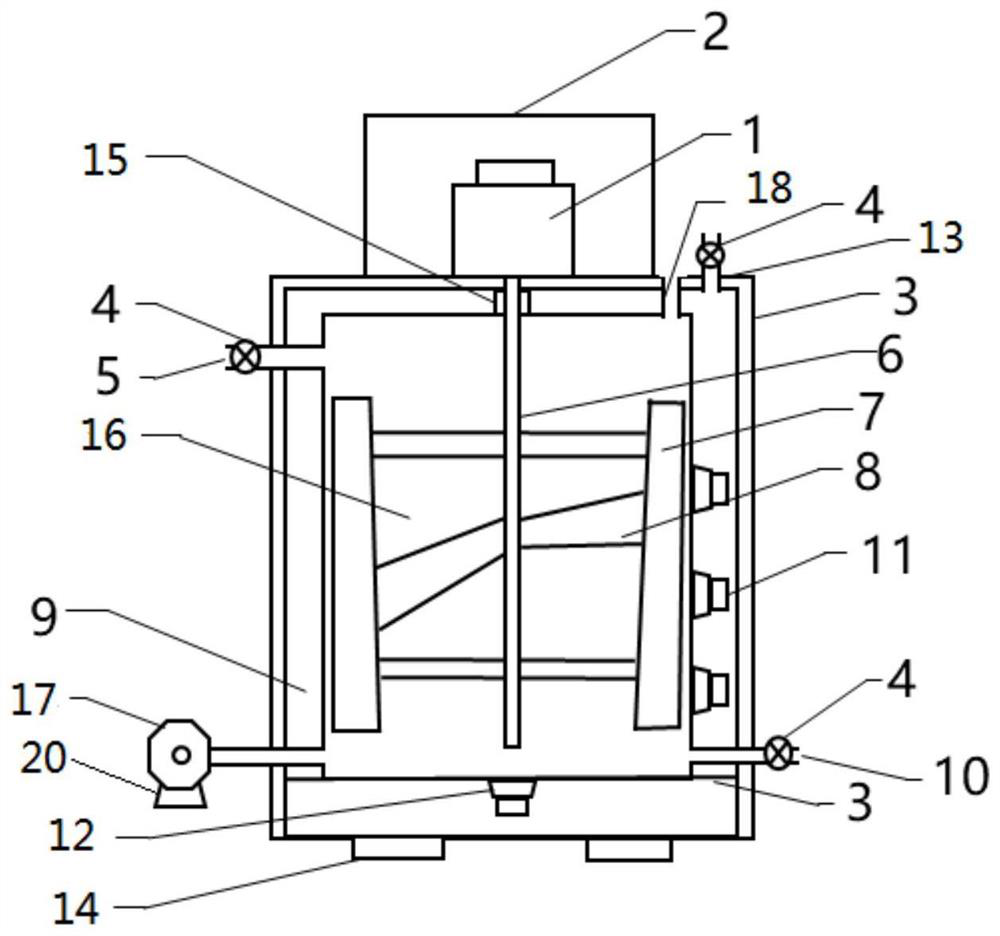

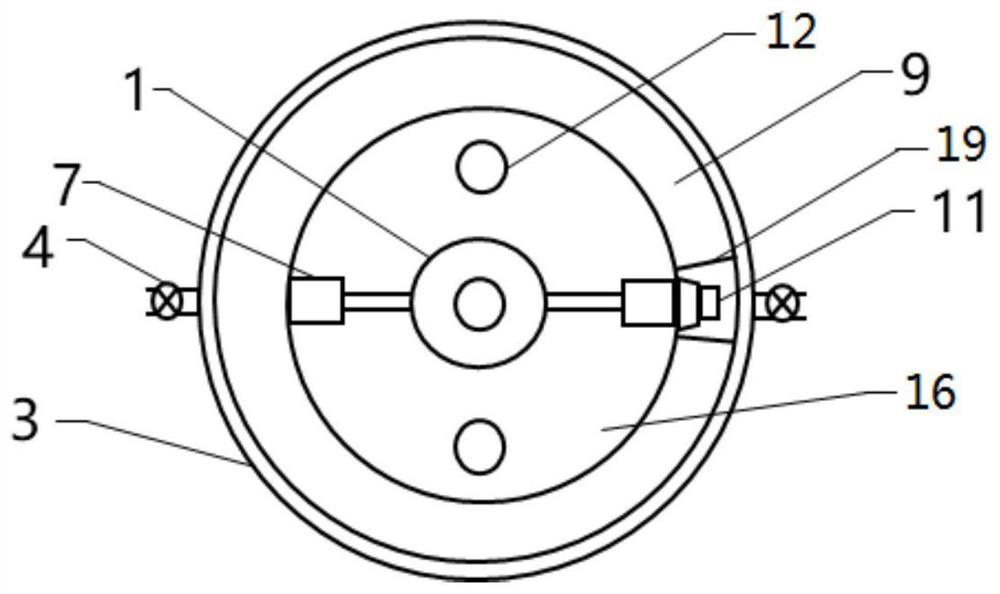

[0041] like figure 1 and figure 2 The shown ice cream maker includes a freezing cavity, a first ultrasonic transducer, a second ultrasonic transducer, an air compressor and a stirring mechanism, and the first ultrasonic transducer is attached to the side wall of the freezing cavity , the second ultrasonic transducer is arranged at the lower part of the freezing cavity, the direction in which the first ultrasonic transducer generates ultrasonic waves and the direction in which the second ultrasonic transducer produces ultrasonic waves are perpendicular to each other, and the air compressor and the refrigeration The cavity is connected, and the freezing cavity is provided with a stirring mechanism. In this embodiment, there are three first ultrasonic transducers, and the three first ultrasonic transducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com