A method for preparing oral functional jaw pads by combining hot-pressed film and 3D direct printing

A hot-pressed film and 3D technology, which is applied in the field of oral surgery, can solve the problems of complicated preparation process, uncomfortable wearing, and high difficulty, and achieve the effect of convenient removal and wearing, easy removal and wearing, and simplified production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

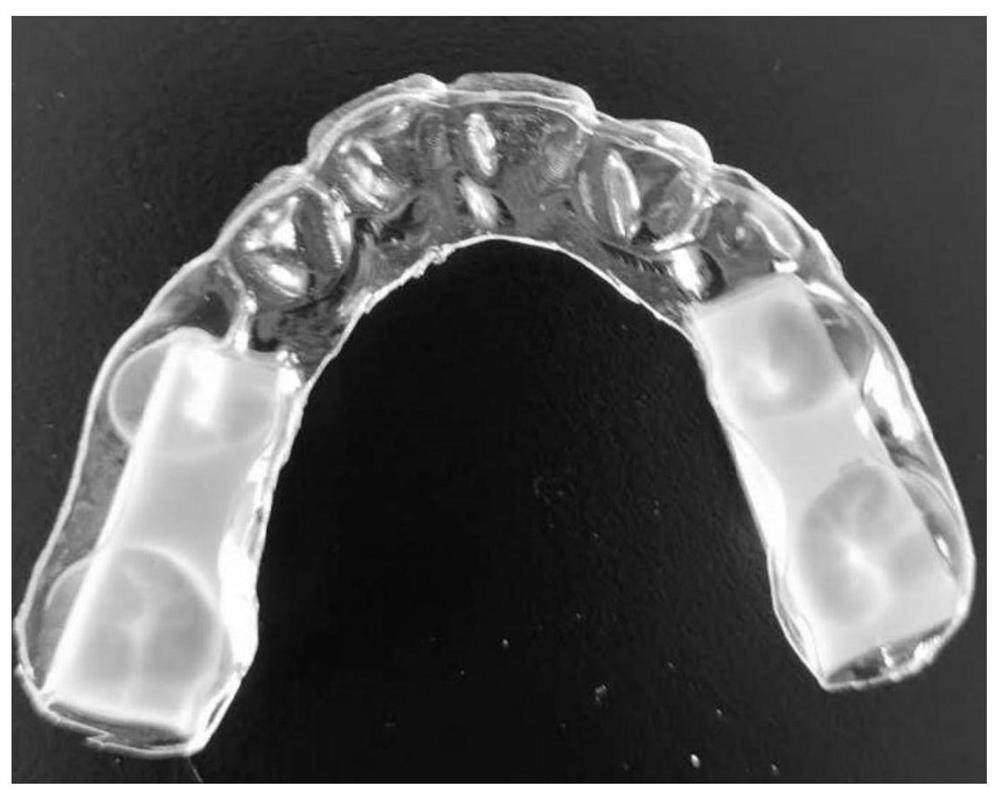

Examples

Embodiment 1

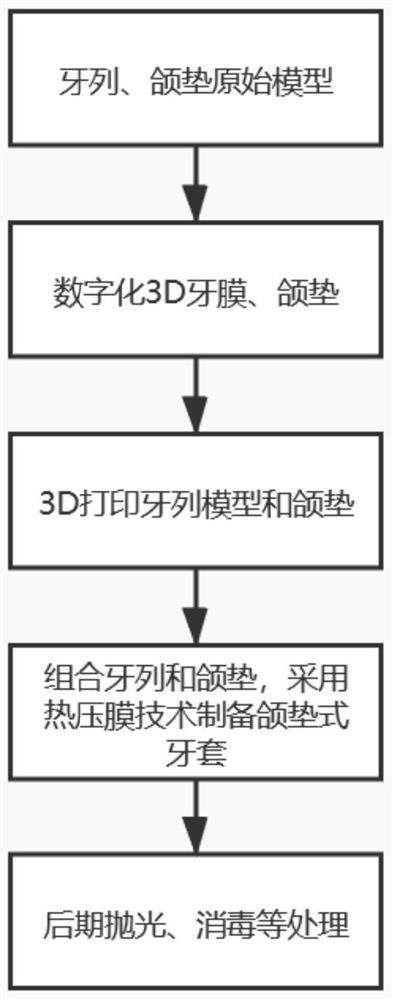

[0031] The specific steps of combining 3D printing and hot pressing film technology described in the present invention are as follows:

[0032] Step 1: Use a 3D scanner to scan the patient's upper dentition to obtain the 3D data of the patient's dental arch outside the body.

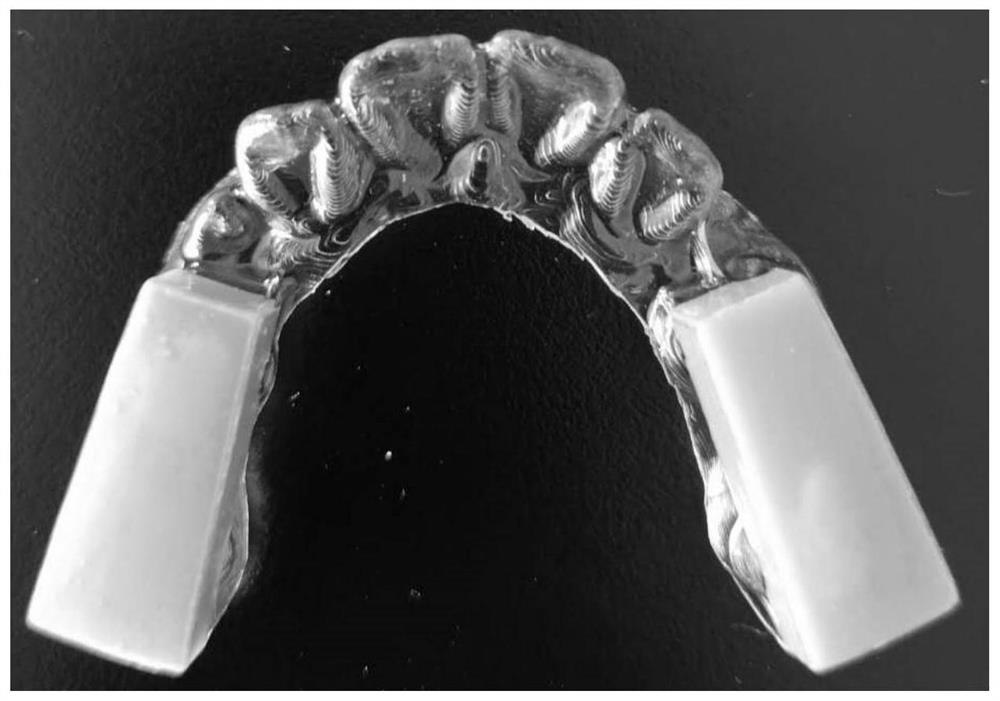

[0033] Step 2: Use high-precision silicone rubber to obtain the patient's occlusal record, and record the position of the midline and the mesiobuccal cusp of the left and right first molars. Use a 3D scanner to scan the occlusal record and convert it into digital jaw pad data. To determine the required jaw pad height and the corresponding jaw position for an open bite.

[0034] Step 3: Import the dentition data in Step 1 into Magics software for model restoration, flatten the model gums to make the bottom surface flat, save and export the model STL file;

[0035] Model repair, the steps include but are not limited to jaw pad edge trimming, flash removal, loopholes, anti-triangular and bad edge repairs. ...

Embodiment 2

[0053] (1) Use a three-dimensional scanner to scan the patient's upper dentition to obtain dentition data, that is, the three-dimensional data of the patient's upper dental arch in vitro;

[0054] (2) Obtain the patient's occlusal records, record the midline and the positions of the left and right premolars or the mesiobuccal cusps of the reserved molars, and then use the 3D scanner to scan the occlusal records; to determine the height of the jaw pad required for opening the occlusion and the corresponding position Dental pad position relationship.

[0055] (3) Import the dentition data in step (1) into Magics software for model restoration, cut flat model gingiva to make the bottom surface flat and save it, and export the model STL file;

[0056] (4) Data processing: Import the corrected dentition data in step (3) and the occlusal record data in step (2) into freeform software for jaw pad design: take the occlusal surface as the reference maxillofacial surface, and design in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com