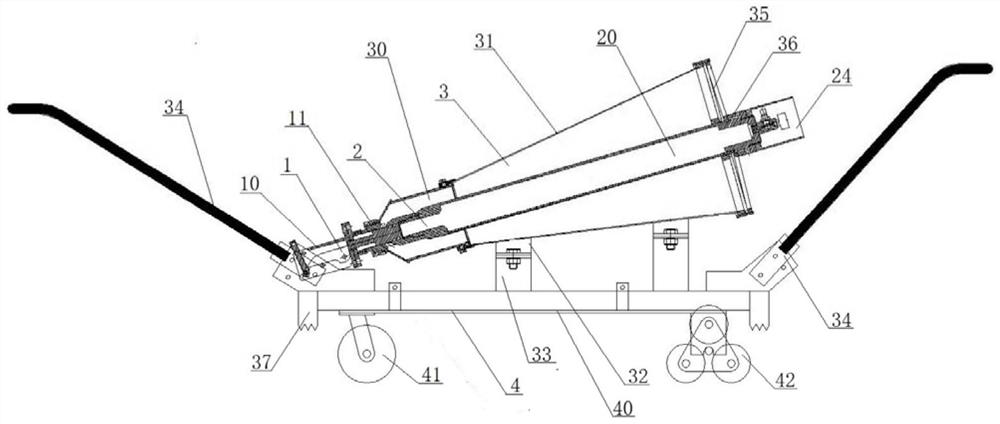

Trolley type fire extinguisher

A fire extinguisher, cart-type technology, applied in fire rescue, medical science, dentistry, etc., can solve the problems of unsecured fire extinguishers, small powder storage capacity, and low spray efficiency, and achieve novel structure and fire extinguishing efficiency. High, fast jet effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

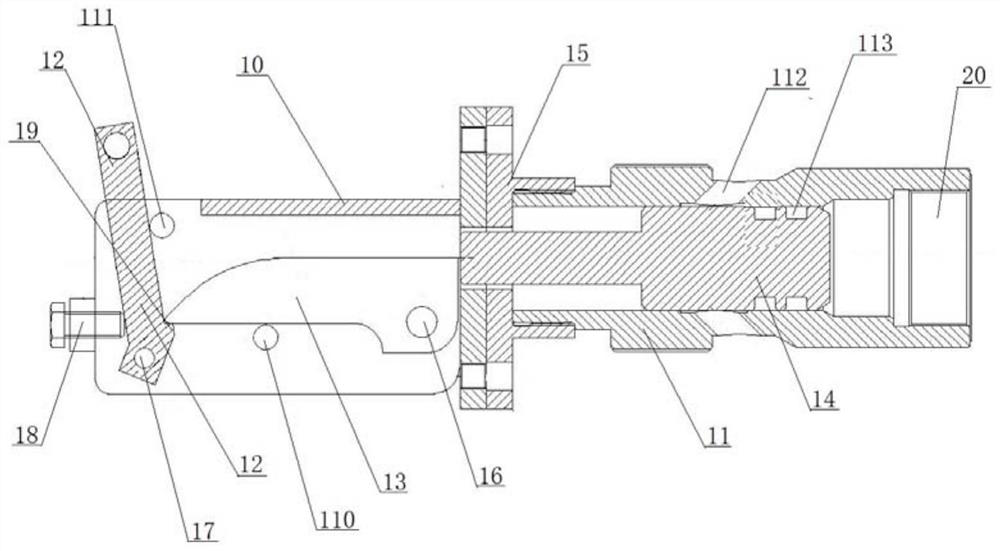

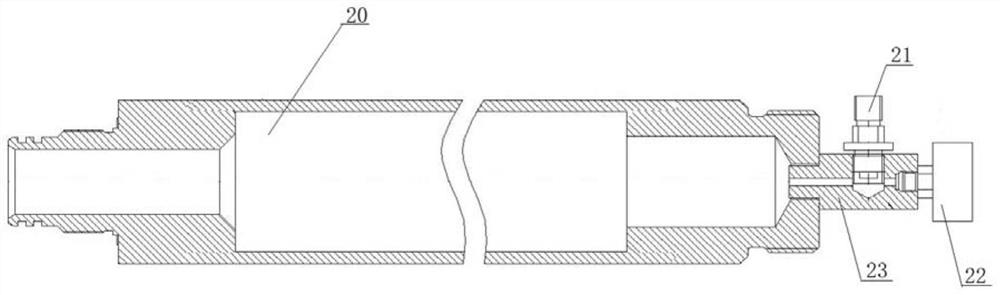

[0033]A cart-type fire extinguisher, comprising a gas storage mechanism 2 and a material storage mechanism 3, the fire extinguisher also includes a trigger mechanism 1, the gas storage mechanism 2 guides high-pressure gas into the material storage mechanism 3 through the trigger of the trigger mechanism 1 to realize the eruption of the fire extinguisher; the gas storage The mechanism 2 includes a gas storage chamber 20, the front end of the gas storage chamber 20 is connected with the trigger mechanism 1, and the rear end of the gas storage chamber 20 is connected with an inflator; 11 is provided with a piston 14, and the jet pipe 11 is slidably matched with the piston 14; the front end of the jet pipe 11 is fixed with a blocking plate 15 through threaded connection, and the front end of the blocking plate 15 is fixed with a trigger bracket 10 through a flange connection, and the trigger bracket 10 includes Two vertical boards arranged in parallel, a rotating shaft I16 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com