Feed raw material impurity removing and collecting device

A technology of feed raw materials and collection devices, which is applied in the direction of feed, solid separation, filtering and screening, etc., and can solve the problems of affecting healthy growth and mixing sacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

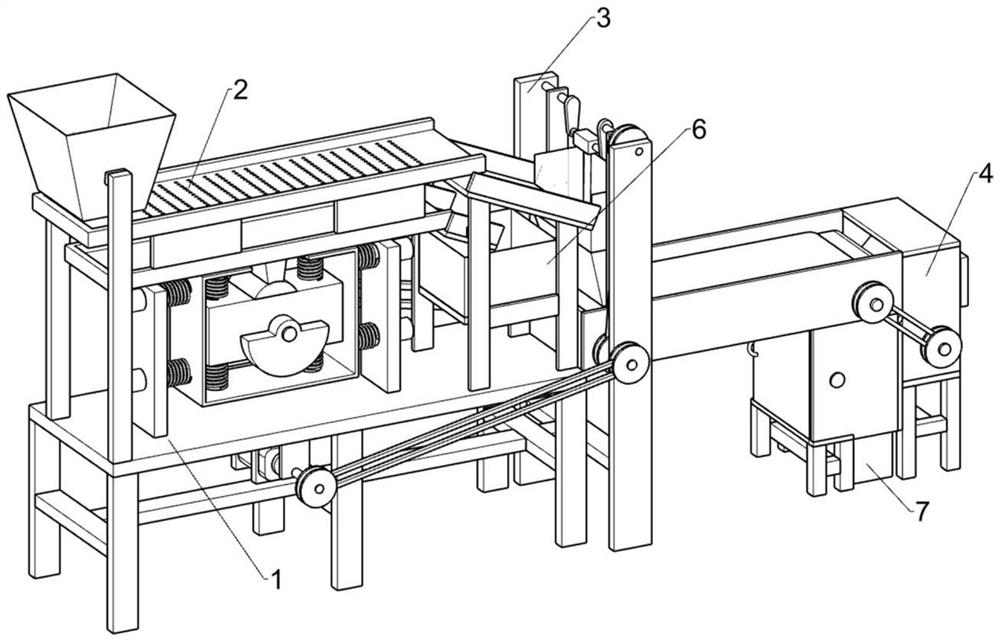

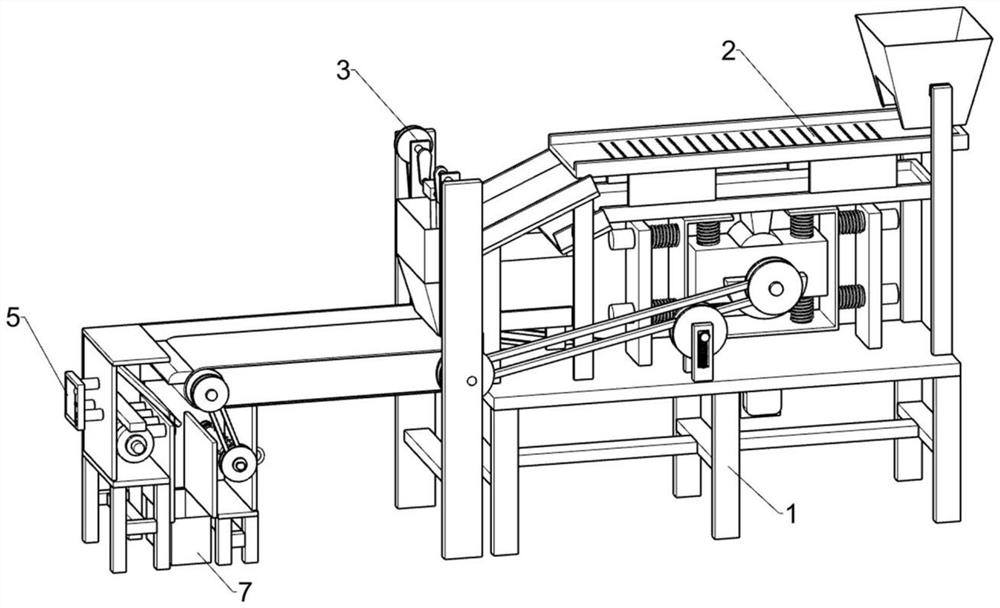

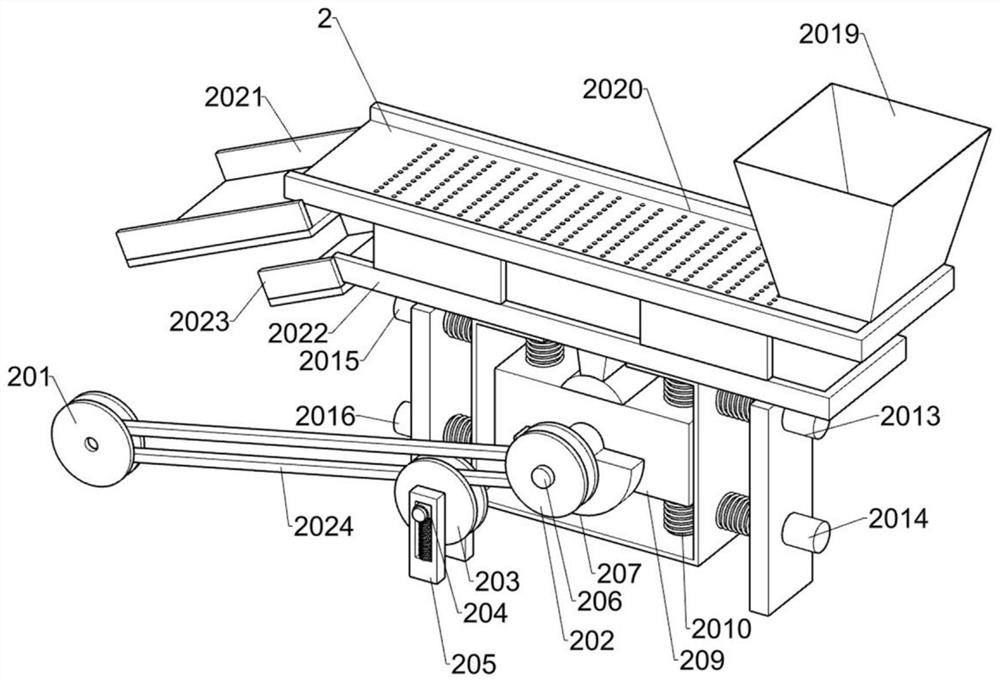

[0027] A feed raw material removal and collection device, such as Figure 1-7As shown, it includes an underframe 1, a sand removal mechanism 2, a flattening mechanism 3, a collection mechanism 4, a control panel 5, a first collection box 6 and a second collection box 7; the underframe 1 is connected to the sand removal mechanism 2; The chassis 1 is connected with the leveling mechanism 3; the chassis 1 is connected with the collection mechanism 4; the chassis 1 is connected with the control panel 5; the chassis 1 is connected with the first collection box 6; the chassis 1 is connected with the second collection box The box 7 is connected; the sand removal mechanism 2 is connected with the flattening mechanism 3; the first collection box 6 is arranged under the sand removal mechanism 2; the flattening mechanism 3 is connected with the collection mechanism 4; the second collection box 6 is arranged under the collection mechanism 4 Box 7.

[0028] When in use, first place the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com