A kind of composite flocculant for printing and dyeing wastewater treatment

A composite flocculant, printing and dyeing wastewater technology, applied in textile industry wastewater treatment, water/sewage treatment, adsorption water/sewage treatment, etc. Operating and post-treatment costs, flocculation excitation effect and effect of good gel nucleation and high crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

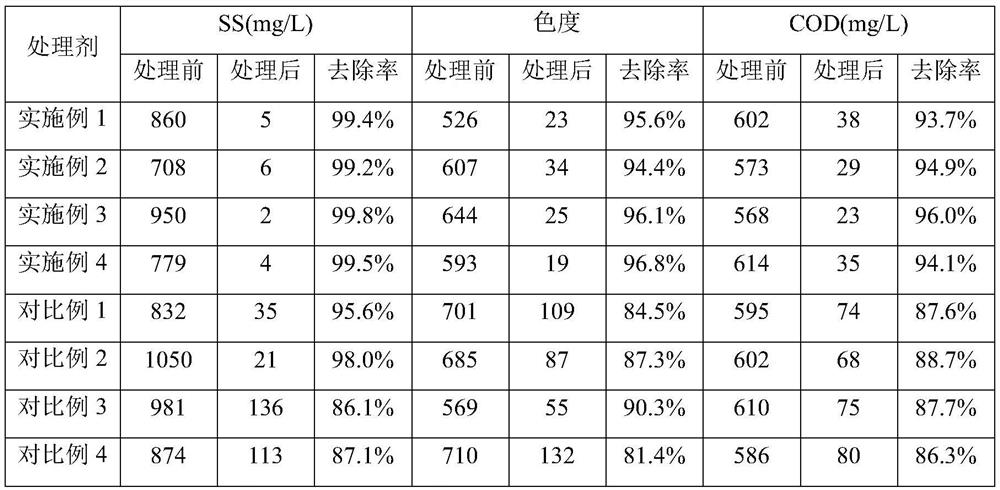

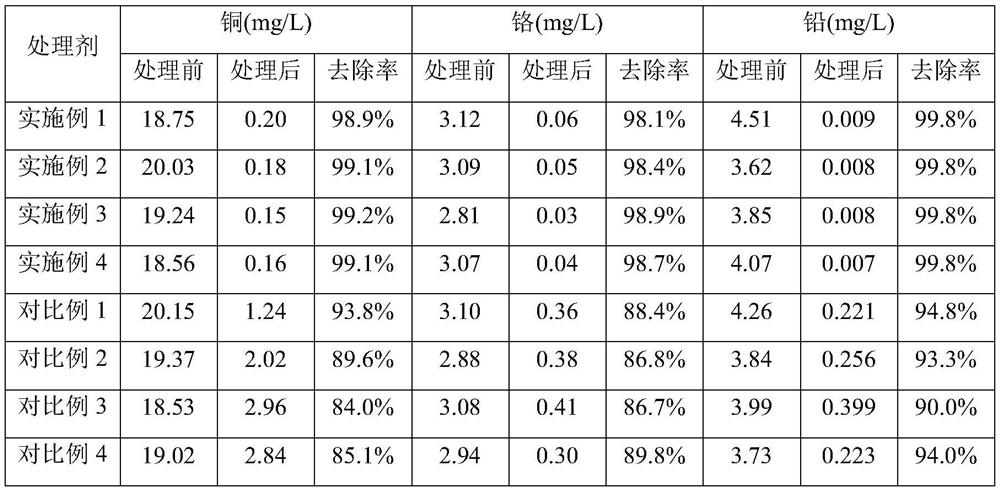

Examples

Embodiment 1

[0034] A composite flocculant for printing and dyeing wastewater treatment, prepared from the following raw materials in parts by weight: 15 parts of activated carbon fiber, 4 parts of acrylamide, 0.003 parts of initiator, 2 parts of sodium carboxymethyl cellulose, and 5 parts of polyvinyl alcohol , 3 parts of crosslinking agent, 3 parts of polyethyleneimine-cellulose composite material, 10 parts of starch xanthate, 25 parts of modified bentonite.

[0035] Further, the activated carbon fiber is obtained from biomass material through hydrothermal carbonization and sulfuric acid activation; its preparation method is as follows:

[0036] (1) removing impurities, washing and drying the biomass material for subsequent use;

[0037](2) Put the dried biomass material into the hydrothermal reaction kettle, add deionized water, immerse the biomass material, program the temperature to 220 ° C, react for 24 hours, and then cool to room temperature;

[0038] (3) The reacted substance is ...

Embodiment 2

[0051] A composite flocculant for printing and dyeing wastewater treatment, prepared from the following raw materials in parts by weight: 17 parts of activated carbon fiber, 6 parts of acrylamide, 0.004 part of initiator, 5 parts of sodium carboxymethyl cellulose, and 9 parts of polyvinyl alcohol , 4 parts of crosslinking agent, 4 parts of polyethyleneimine-cellulose composite material, 12 parts of starch xanthate, and 30 parts of modified bentonite.

[0052] Further, the activated carbon fiber is obtained from biomass material through hydrothermal carbonization and sulfuric acid activation; its preparation method is as follows:

[0053] (1) removing impurities, washing and drying the biomass material for subsequent use;

[0054] (2) Put the dried biomass material into the hydrothermal reaction kettle, add deionized water, immerse the biomass material, program the temperature to 220 ° C, react for 24 hours, and then cool to room temperature;

[0055] (3) The reacted substance...

Embodiment 3

[0068] A composite flocculant for printing and dyeing wastewater treatment, prepared from the following raw materials in parts by weight: 23 parts of activated carbon fiber, 9 parts of acrylamide, 0.005 part of initiator, 7 parts of sodium carboxymethylcellulose, and 13 parts of polyvinyl alcohol , 5 parts of crosslinking agent, 4.5 parts of polyethyleneimine-cellulose composite material, 14 parts of starch xanthate, and 32 parts of modified bentonite.

[0069] Further, the activated carbon fiber is obtained from biomass material through hydrothermal carbonization and sulfuric acid activation; its preparation method is as follows:

[0070] (1) removing impurities, washing and drying the biomass material for subsequent use;

[0071] (2) Put the dried biomass material into the hydrothermal reaction kettle, add deionized water, immerse the biomass material, program the temperature to 220 ° C, react for 24 hours, and then cool to room temperature;

[0072] (3) The reacted substan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com