Railway vehicle chassis boundary beam connecting structure suitable for drum-shaped vehicle body

A rail vehicle and connection structure technology, which is applied in the field of rail vehicles, can solve the problems of large fatigue stress at the joint between the side wall column and the floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

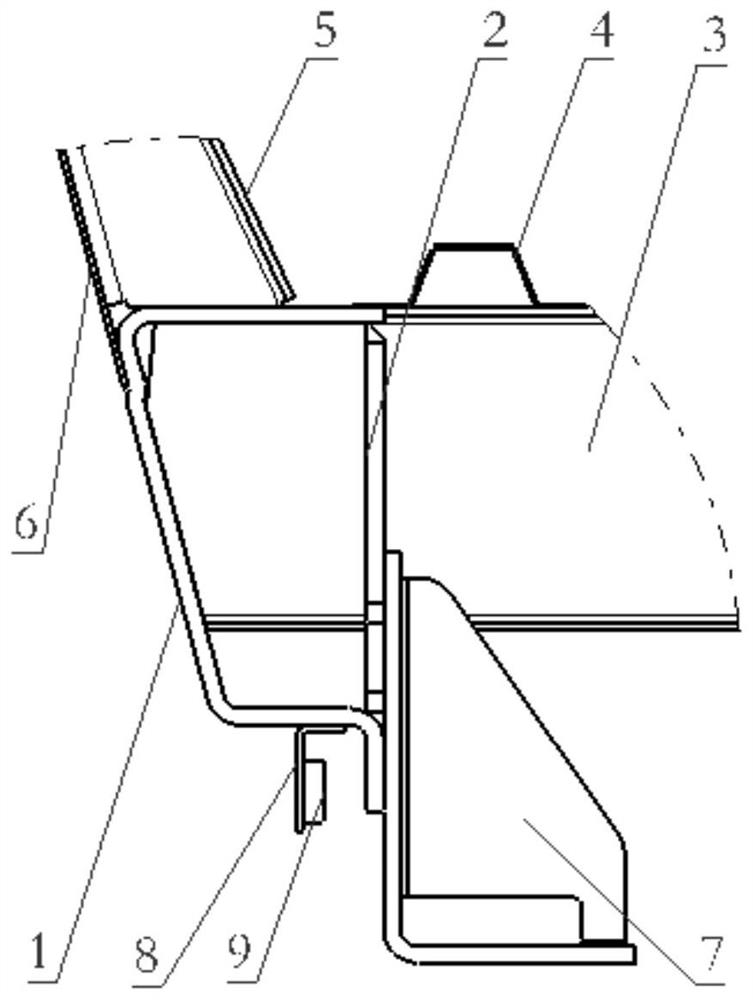

[0016] Embodiments of the present invention will be explained below in conjunction with the accompanying drawings.

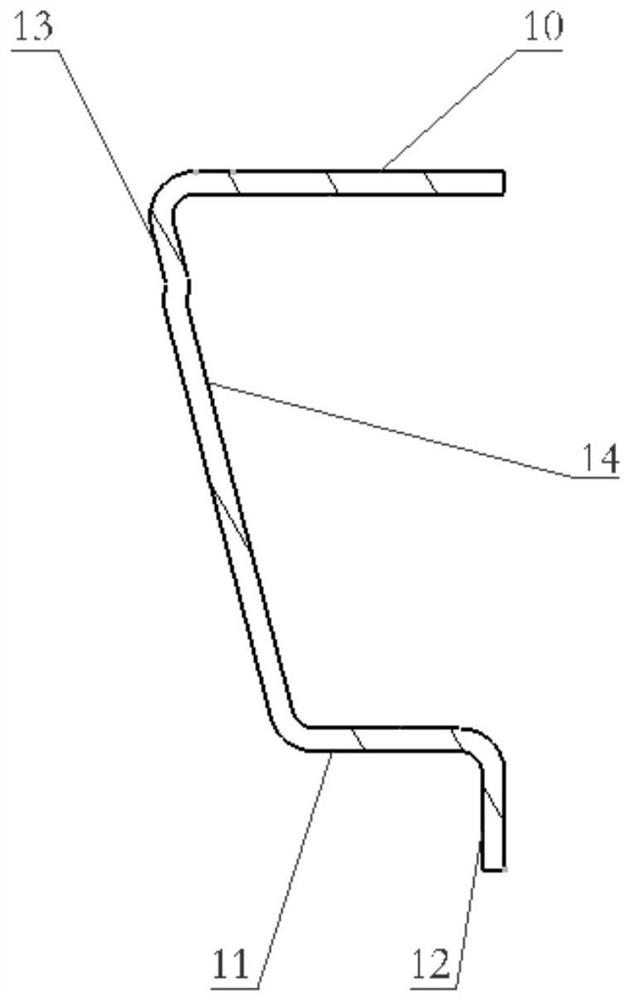

[0017] Such as figure 1 , figure 2 As shown, this embodiment is suitable for the connection structure of the side beams of the rail vehicle chassis of the drum-shaped car body, mainly including the side beams of the chassis 1, the cross beams of the chassis 3, the side wall columns 5, the side wall panels 6, and the equipment hangers under the vehicle 7 and chassis floor 4. Among them, the section of the underframe side beam 1 has a groove structure, and the height dimension is relatively large. The lower wing surface 11 is provided with a vertical flange 12 downwards to improve the connection strength between the equipment hanger 7 under the vehicle and the underframe side beam 1. At the same time, the vertical stiffness and bending resistance of the underframe side beam 1 are improved; the side 14 of the underframe side beam 1 is provided with an outwardly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com