Universal ethylene cracking furnace coil hanging test equipment and test method

A general-purpose technology for ethylene cracking furnaces, which is applied to load-hanging components, transportation and packaging, etc., and can solve problems affecting the service life of ethylene cracking furnace coils, large center distance deviations of pipe fittings, and twist-shaped coils, etc., to achieve Effects of cost reduction, life extension, and labor reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below.

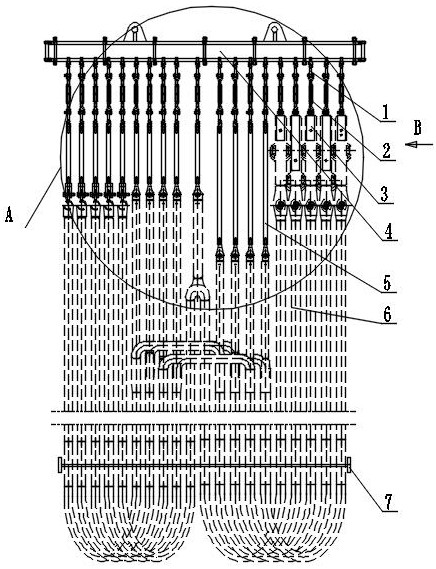

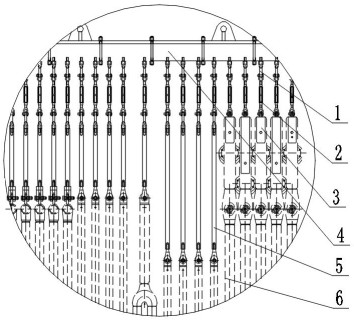

[0031] Referring to the accompanying drawings, the general-purpose ethylene cracking furnace coil hanging test tooling includes a main suspension beam 4 and a universal suspension ring 1, and is characterized in that: the lower part of the main suspension beam 4 is connected with several universal suspension rings 1, and the universal suspension ring 1. The lower part is connected with a UU-shaped turnbuckle screw 2; the top of one end of the coil 6 is connected to the UU-shaped turnbuckle 2 through a bu-shaped tube lifting rod tooling 3, and the top of the other end of the coil 6 is connected to the UU-shaped turnbuckle 2 through an intermediate connector 5; The lower part of the coil 6 is provided with auxiliary tooling 7 .

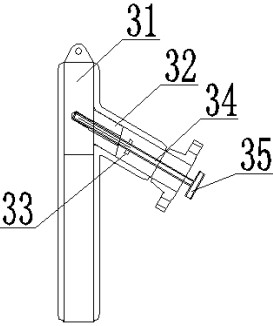

[0032] In this preferred embodiment, the 1-shaped tube lifting boom tooling 3 includes a main boom 31, a support boom 32 is arranged obliquely on the side of the main boom 31, and a handle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com