A production process of bulk tamping coke

A production process and coke technology, applied in the production process field of tamping coke, can solve the problems of high proportion of coking and fertilizer coal, complicated operation, poor matrix strength, etc., to meet the needs of coke quality, overcome process defects, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

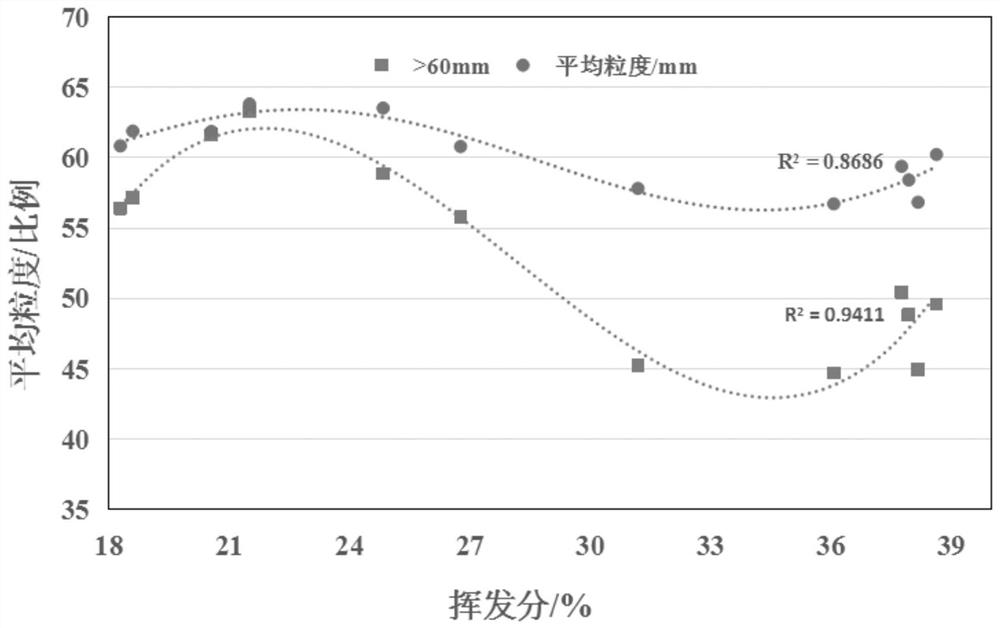

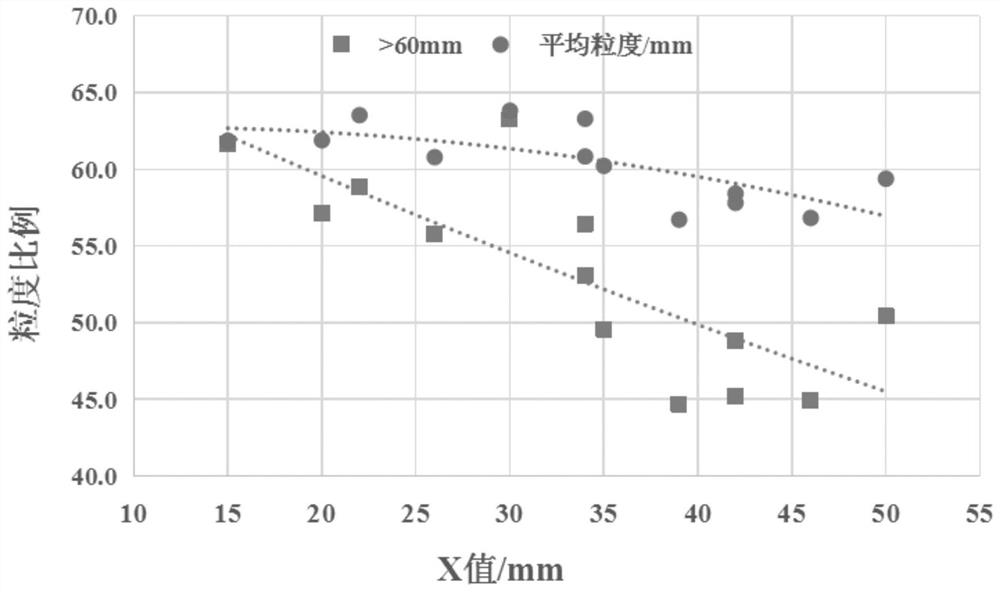

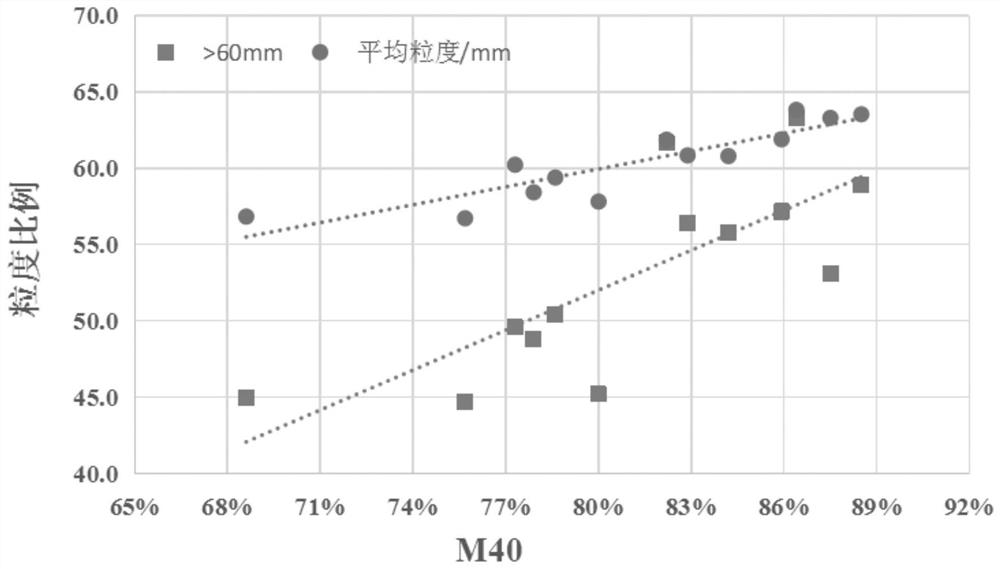

[0058] According to the V of a single coking coal listed in Table 1 daf and X value, to determine the high volatile high shrinkage coal H 煤 Including B coal, C coal, D coal, E coal; medium volatile and medium shrinkage coal M 煤 Including G coal, H coal, J coal, K coal, L coal, low volatile non-shrinkage coal L 煤 Including M coal, O coal, and P coal; among them, A coal has high X, I coal ≥ 60mm has a small proportion, and N coal is a mixed coal, which is not applicable.

[0059] The ratio of each component in embodiment 1 to embodiment 7 is as shown in table 2, carry out coal blending according to table 2, control H 煤 Mass percentage 20%~30%, M 煤 Mass percentage 48%~60%, L 煤 The mass percentage is 17%~22%, and the sum is 100%.

[0060] Table 2

[0061]

[0062] Various performance indicators of the blended coal in Examples 1 to 7 were detected, as shown in Table 3.

[0063] table 3

[0064]

[0065] As can be seen from Table 3, the indicators of the blended coal o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com