Accurate control production method of alloyed hot-galvanized IF steel clad layer for automotive outer plate

A production method and alloying technology, applied in hot-dip galvanizing process, metal material coating process, coating, etc., can solve problems such as dezincification quality objections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

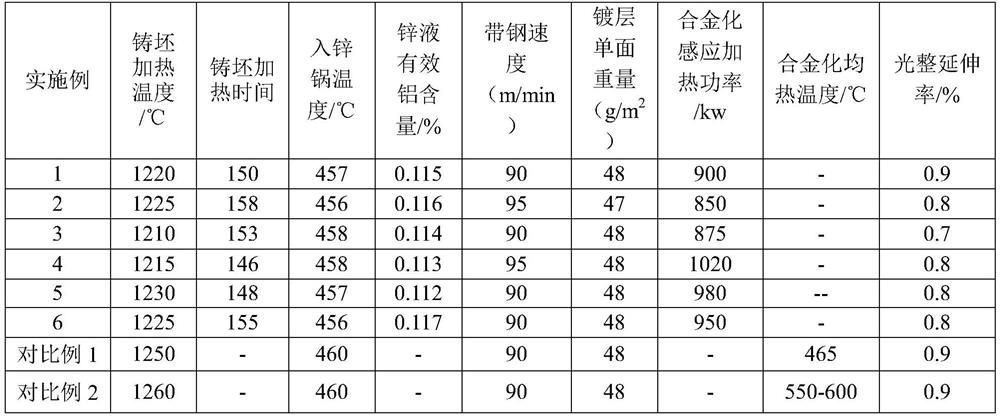

[0086] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

[0087] Each embodiment of the present invention is produced according to the following steps:

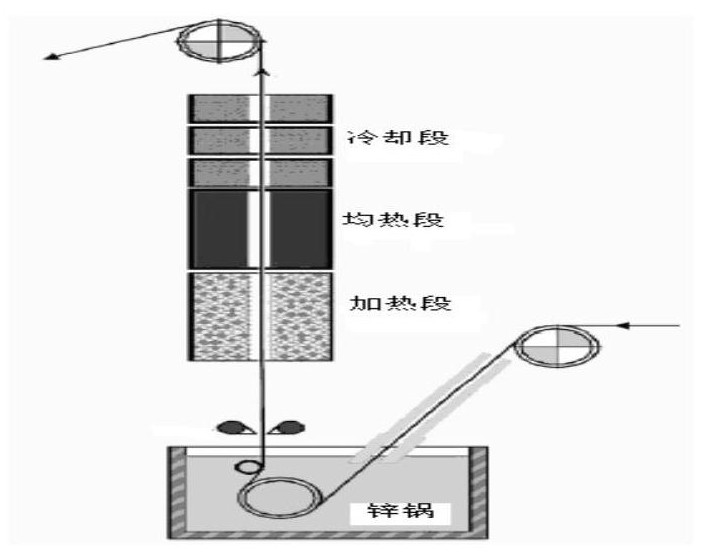

[0088] The method includes a smelting process, a hot rolling process, an acid rolling process, a galvanizing process, an alloying process, and a skin pass process, wherein,

[0089]1) Smelting process: Select different IF steel components for smelting according to user needs, and strictly control the content of P and S elements, of which P≤0.015%, S≤0.012%;

[0090] 2) Hot rolling: during the hot rolling process, the heating temperature is 1200-1230°C, and the soaking time is 120-160 minutes; at the same time, the phosphorus removal water is fully opened during the rough rolling and finishing rolling processes;

[0091] 3) Pickling: the pickling speed is less than or equal to 160m / min, and the flatness of the plate is ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com