Electro-hydraulic control system for tractor

A control system and tractor technology, applied in the field of tractors, can solve the problems of electronic control, low degree of intelligence, low operation efficiency, heavy and laborious operation, etc., and achieve the effect of improving the degree of automation, improving comfort and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

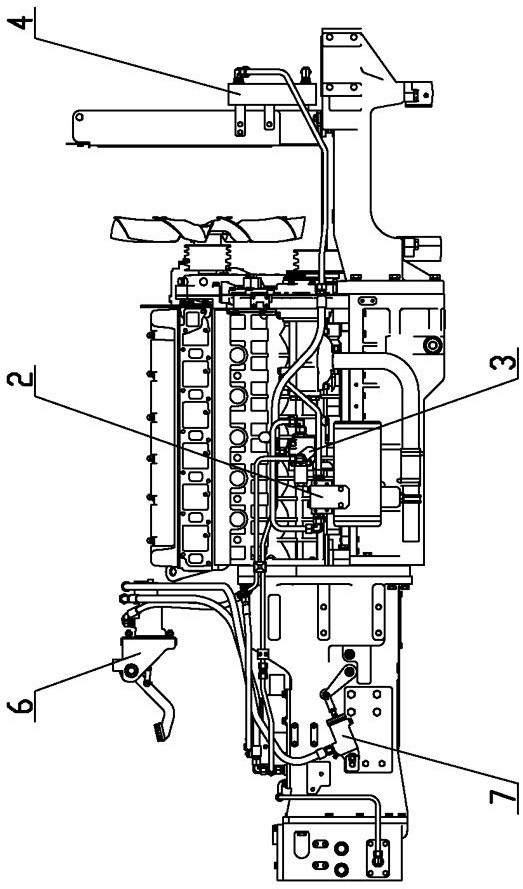

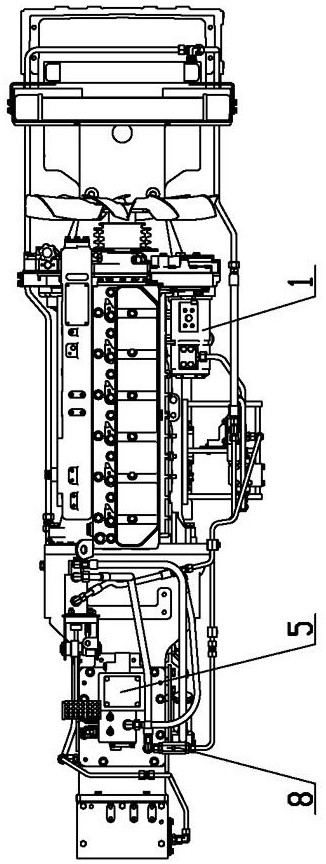

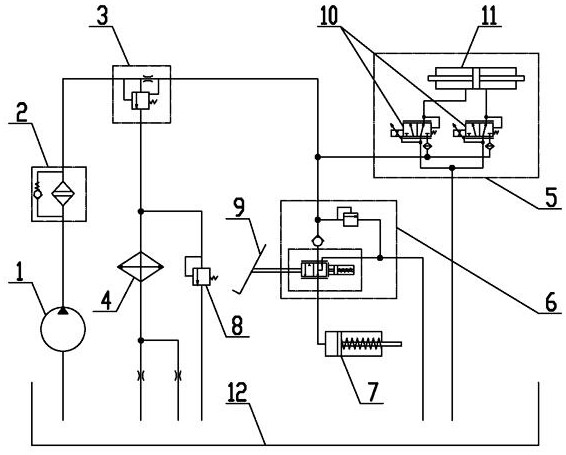

[0021] Referring to the accompanying drawings, the specific implementation is as follows:

[0022] An electro-hydraulic control system for tractors, including a fuel tank 12, a gear pump 1, an oil filter 2, a single-way stable diverter valve 3, an electro-hydraulic control reversing mechanism 5, a clutch booster pump 6, a clutch booster cylinder 7, and a gear pump 1 Installed in the gear room of the engine, the oil filter 2 and the single-way stable diverter valve 3 are installed on the SCR bracket on the side of the engine, the oil inlet of the gear pump 1 is connected with the oil tank 12, and the oil outlet of the gear pump 1 is connected with the oil filter The oil inlet of oil filter 2 is connected, and the oil outlet of oil filter 2 is connected with the oil inlet of single-way stable diverter valve 3.

[0023] The electro-hydraulic control reversing mechanism 5 is installed on the top of the front box of the gearbox, including two electric proportional pressure reducing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com