Lightweight design method of hybrid power bus framework

A lightweight design, hybrid technology, applied in the automotive field, can solve problems such as single optimization target, and achieve the effect of improving collision safety and reducing acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and tables, but the embodiment should not be construed as limiting the present invention.

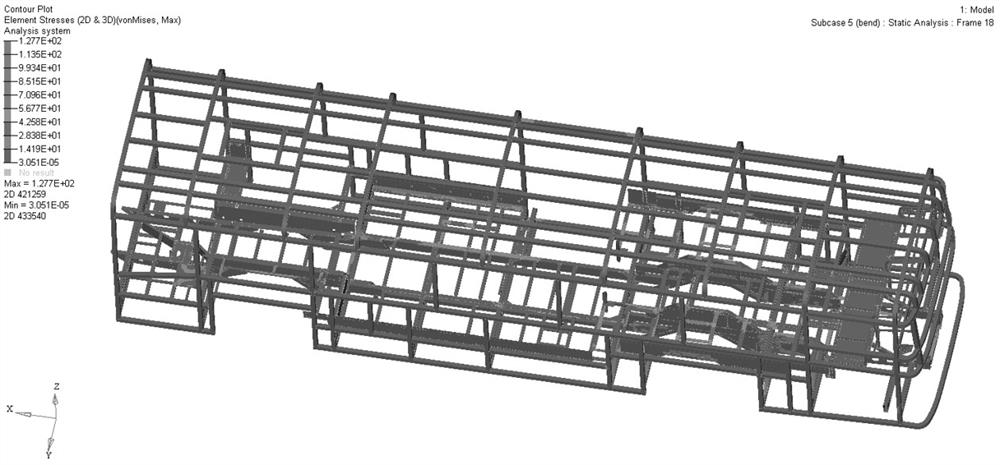

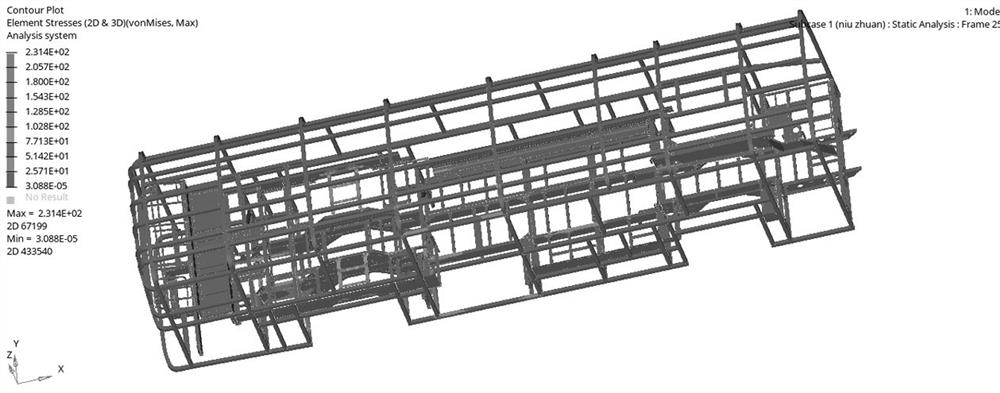

[0048]The invention is likeFigure 1 to Figure 16 , Table 1 to Table 7 show:

[0049]The following describes a lightweight design method for a hybrid bus frame. The frame structure of the bus is a semi-bearing type, including a body frame, a frame, and a floor frame. The material used for the body frame is Q235. The material used for structural steel, frame and floor frame is Q345 structural steel (see Table 1 for material properties); the specific implementation steps are:

[0050]

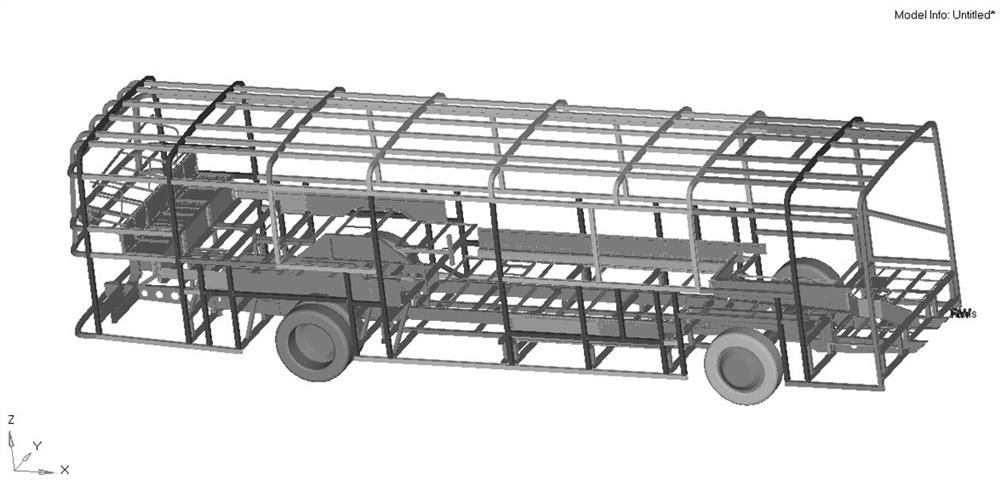

[0051]S1. Establish a finite element model of the passenger car frame for optimization analysis based on CAE technology and finite element method (such asfigure 1 Shown); Among them: the unit size is set to 10mm, the vehicle is equipped with a total of 639298 units and 496238 node...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com