750kV converter transformer outgoing line cylinder structure and assembling method

A technology for converter transformers and outlet barrels, which is applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, inductor/transformer/magnet manufacturing, etc., which can solve the safety hazards of converter transformers, compression coils to The space of the bushing terminal, the inability to fully guarantee the electrical and mechanical strength of the outlet structure, etc., to achieve the effect of ensuring safe operation, easy disassembly and transportation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

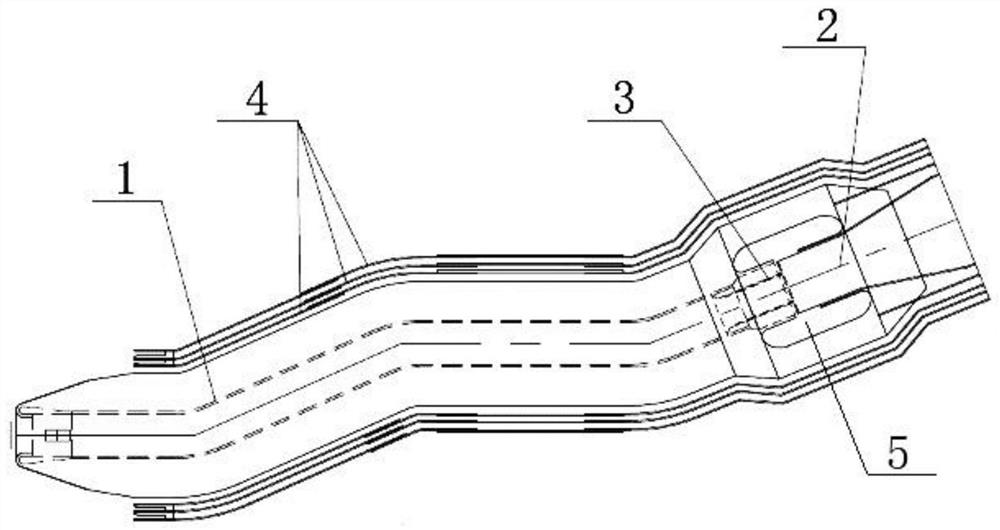

[0028] like figure 1 Shown is a cross-sectional view of the structure of the outlet barrel of the embodiment of the present invention. A 750kV converter transformer outlet barrel structure, including: first aluminum tube insulation 1, second aluminum tube insulation 2, cylindrical insulating plug structure (composed of insulating barrel 3, voltage equalizing ring 5), insulating assembly structure 4 .

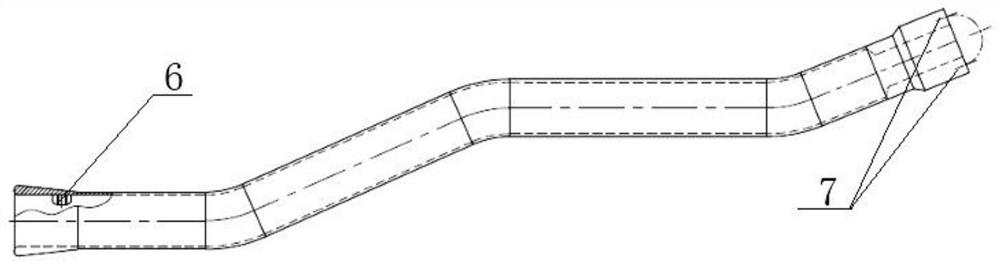

[0029] like figure 2 Shown is a cross-sectional view of the first aluminum tube insulation of the embodiment of the present invention. The first aluminum tube insulation 1 is an S-shaped aluminum tube welded structure with crepe paper insulation on the outer surface, and the length and shape are suitable for the inner space of the transformer; one end of the first aluminum tube insulation 1 is connected to the coil, and the other end is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com