Electric coolant pump

A coolant pump, electric technology, applied in the direction of pumps, pump components, pump devices, etc., can solve the problems of electric coolant pump failure, failure, motor overheating, etc., to reduce heat dissipation, high mechanical pump performance, and reduce waste heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

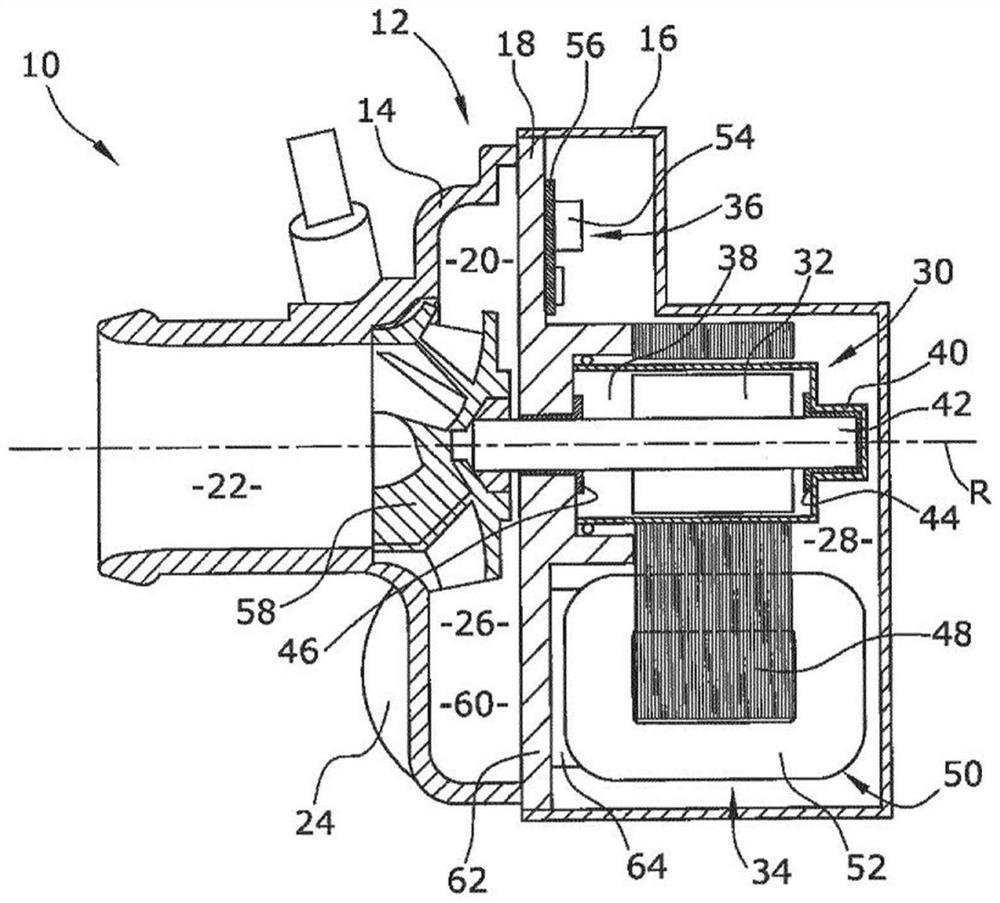

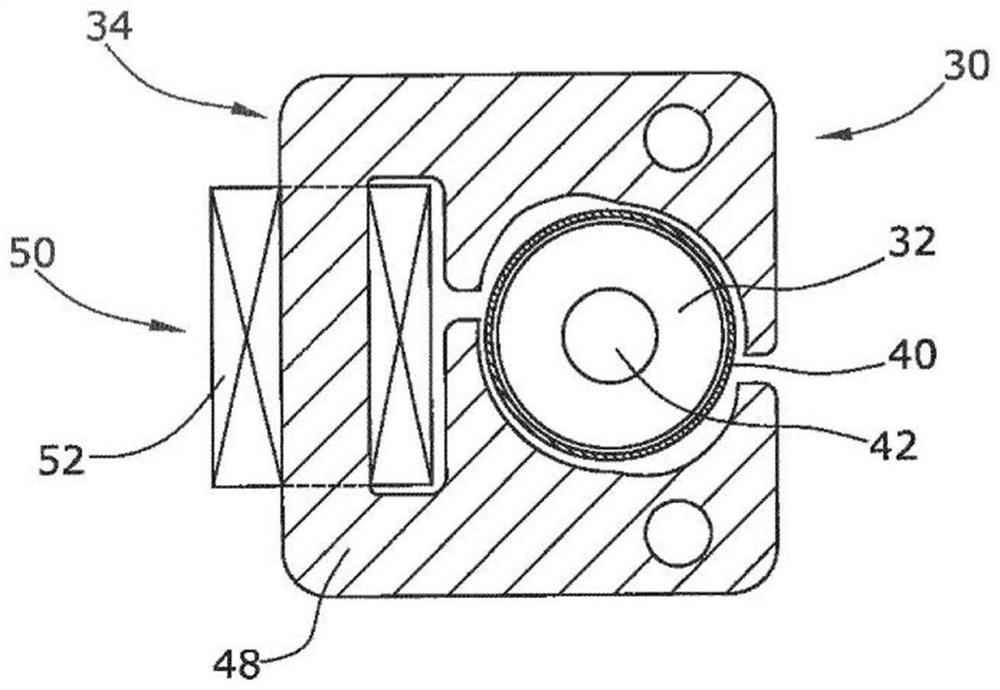

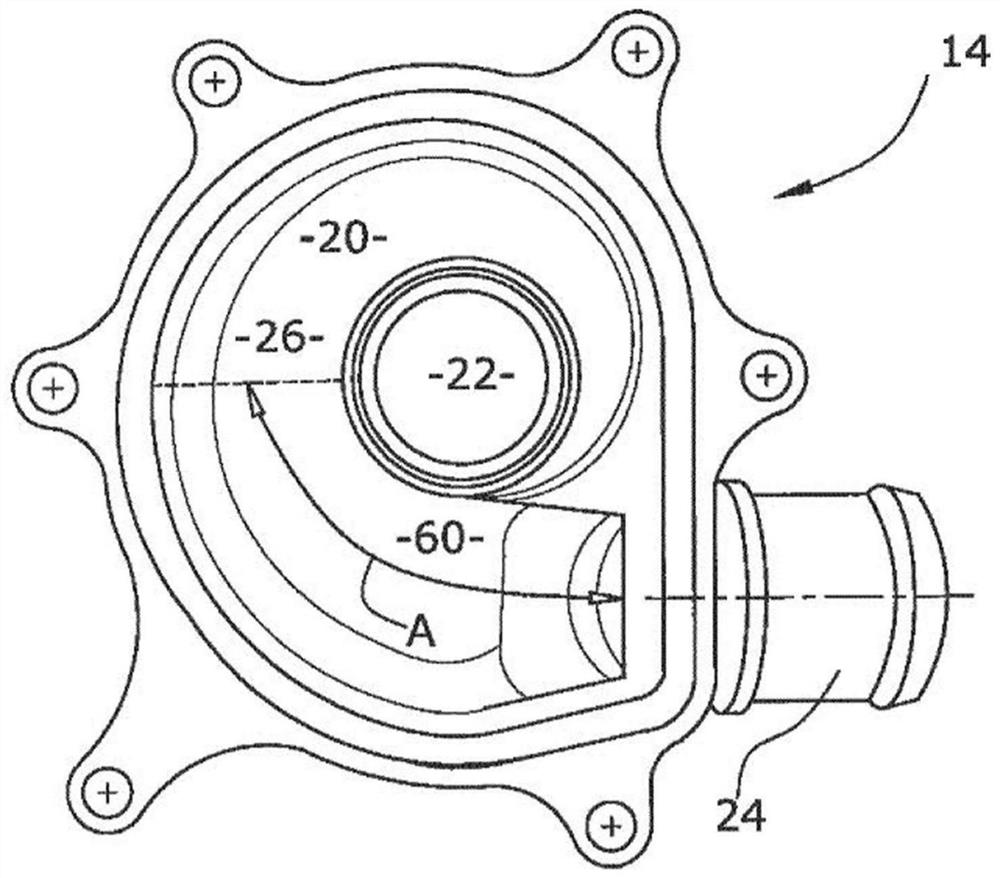

[0024] The electric coolant pump 10 comprises a multipart pump housing 12 with a pumping chamber cover element 14 , a motor chamber cover element 16 and a partition side wall 18 extending essentially in a radial plane. In the present embodiment of the invention, the partition side wall 18 is made of a material with high thermal conductivity, for example aluminum. The pumping chamber cover element 14 and the dividing side wall 18 define a pumping chamber 20 which is filled with coolant during pump operation. The pumping chamber 20 comprises a radially inner pump inlet 22 , a radially outer pump outlet 24 and a pump volute 26 extending in a radial plane from downstream of the pump inlet 22 to the pump outlet 24 . The pump inlet 22 extends substantially in the axial motor direction, and the pump outlet 24 extends substantially in a radial plane, so that the pump inlet 22 is arranged substantially perpendicularly with respect to the pump outlet 24 . The flow cross section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com