Compound feed for laying hens in egg producing period and application of compound feed

A technology for compound feed and egg production period, applied in the field of poultry breeding, can solve the problem of high feed cost, achieve stable egg production rate, meet the peak egg production rate in egg production period, and solve the effect of high feed cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A compound feed for laying hens used in the laying period, by weight, comprising the following components:

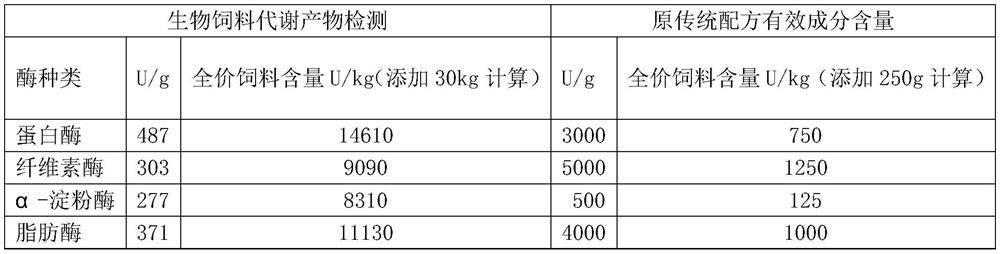

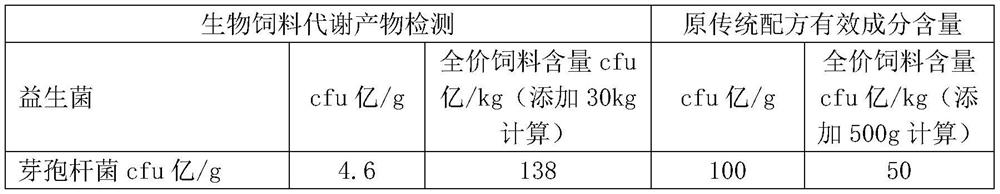

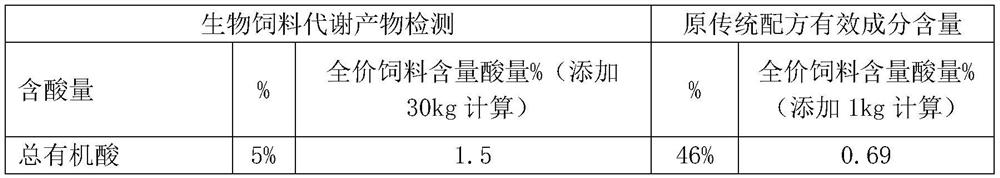

[0032] 600 parts of corn, 200 parts of soybean meal, 40 parts of the first biological fermentation raw material, 20 parts of the second biological fermentation raw material, 15 parts of chili powder, 30 parts of rice bran, 10 parts of soybean oil, 80 parts of stone powder and 19 parts of premix; The first biological fermentation raw material is made from the first fermentation substrate (sorghum, rice, glutinous rice, wheat or corn) through the fermentation and brewing process. The specific process of the fermentation and brewing process is as follows: the first fermentation substrate is fermented to obtain distiller's grains, The distiller's grains are inoculated with yeast, solid-state fermentation, intermediate supplementation of enzyme preparations, deep fermentation for 48-72 hours, and low-temperature drying; enzyme preparations are added during fermentation...

Embodiment 2

[0036] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0037] Described laying hen compound feed comprises the following components by weight:

[0038] 560 parts of corn, 170 parts of soybean meal, 30 parts of the first biological fermentation raw material, 15 parts of the second biological fermentation raw material, 10 parts of chili powder, 20 parts of rice bran, 8 parts of soybean oil, 65 parts of stone powder and 15 parts of premix.

Embodiment 3

[0040] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0041] Described laying hen compound feed comprises the following components by weight:

[0042] 620 parts of corn, 220 parts of soybean meal, 50 parts of the first biological fermentation raw material, 25 parts of the second biological fermentation raw material, 20 parts of chili powder, 50 parts of rice bran, 15 parts of soybean oil, 90 parts of stone powder and 20 parts of premix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com