Special sand blasting equipment for inner tube of electromobile

A technology of sandblasting equipment and electric vehicles, which is applied in the direction of metal processing equipment, used abrasive processing devices, spray guns, etc., can solve the problems of heavy workload of the staff, adhesion and spraying on the outer surface of the inner tube, etc., and achieve sandblasting Good quality, avoid sand splashing, avoid adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

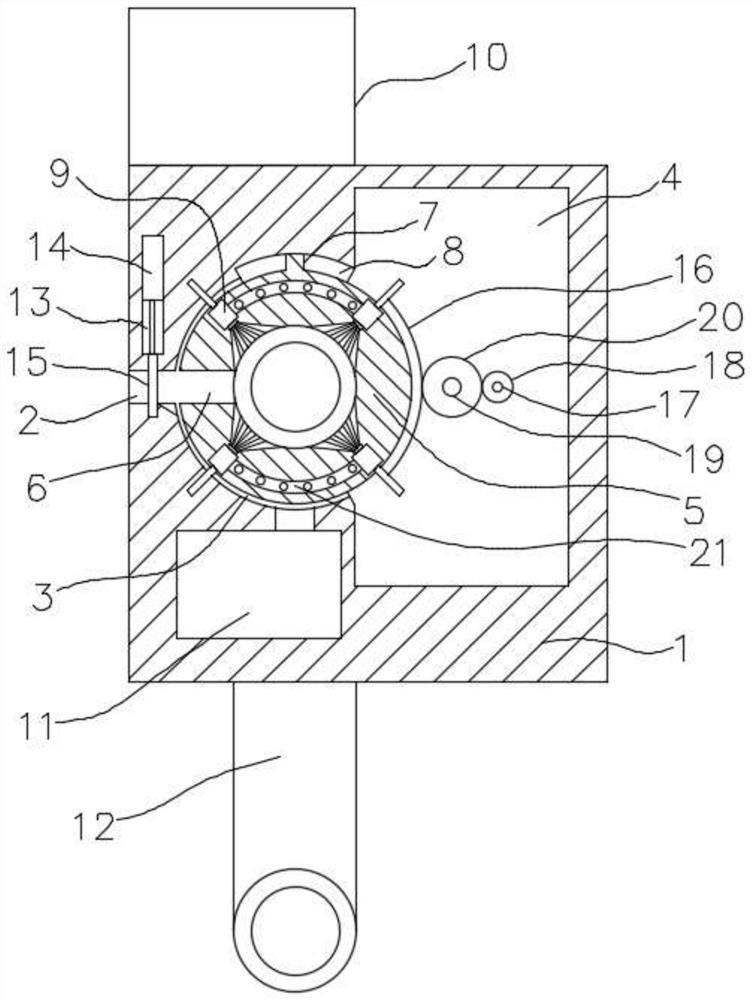

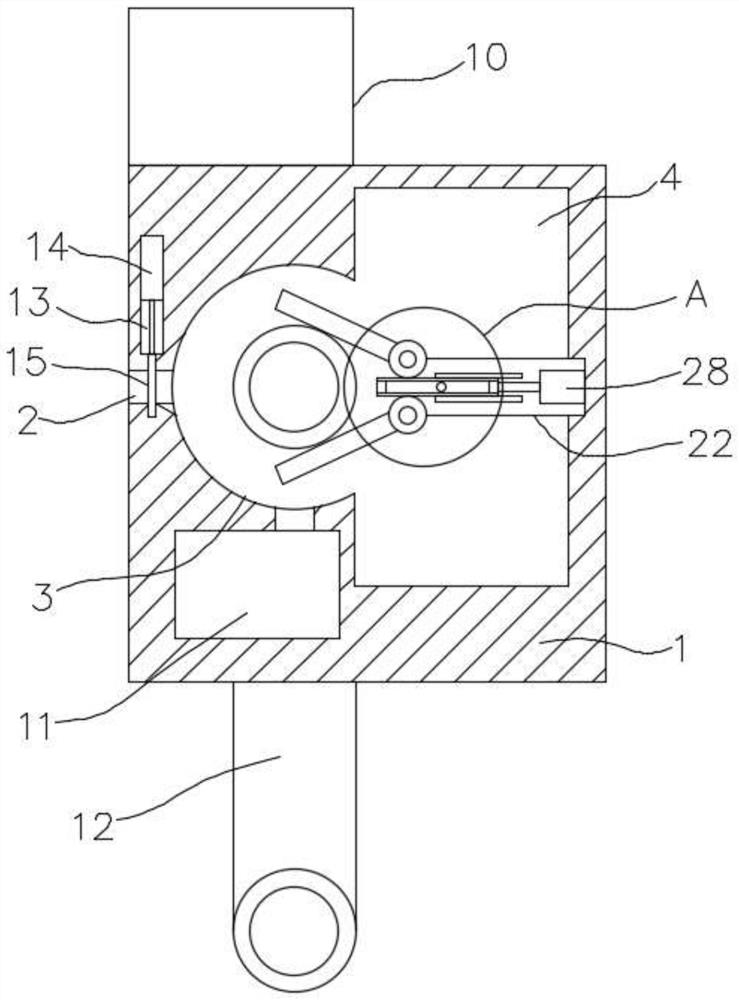

[0026] refer to Figure 1-4 , a kind of sandblasting equipment dedicated to the production of electric vehicle inner tubes, including a body 1, which is provided with a first inlet and outlet 2 connected in sequence from left to right, a sandblasting chamber 3 and an installation chamber 4, and the front and rear sides of the body 1 A transfer port connected to the sandblasting chamber 3 is provided coaxially. The main body 1 is provided with a blocking mechanism above the first inlet and outlet 2. A rotating ring 5 is coaxially provided in the sandblasting chamber 3. The front circumferential direction of the rotating ring 5 is A sandblasting gun 9 is fixedly installed in the prior art. The front of the rotating ring 5 is fixedly connected with an arc-shaped second bump 21 symmetrically up and down. The front inner wall of the sandblasting chamber 3 is provided with a sliding connection with the second bump 21 The upper end of the second rotating ring 5 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com