Blackboard board cutting device with auxiliary locating function

An auxiliary positioning and functional technology, applied in the direction of feeding devices, clamping devices, sawing components, etc., can solve problems such as difficult operation, low efficiency, and potential safety hazards, so as to prevent wood chips from floating and reduce workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

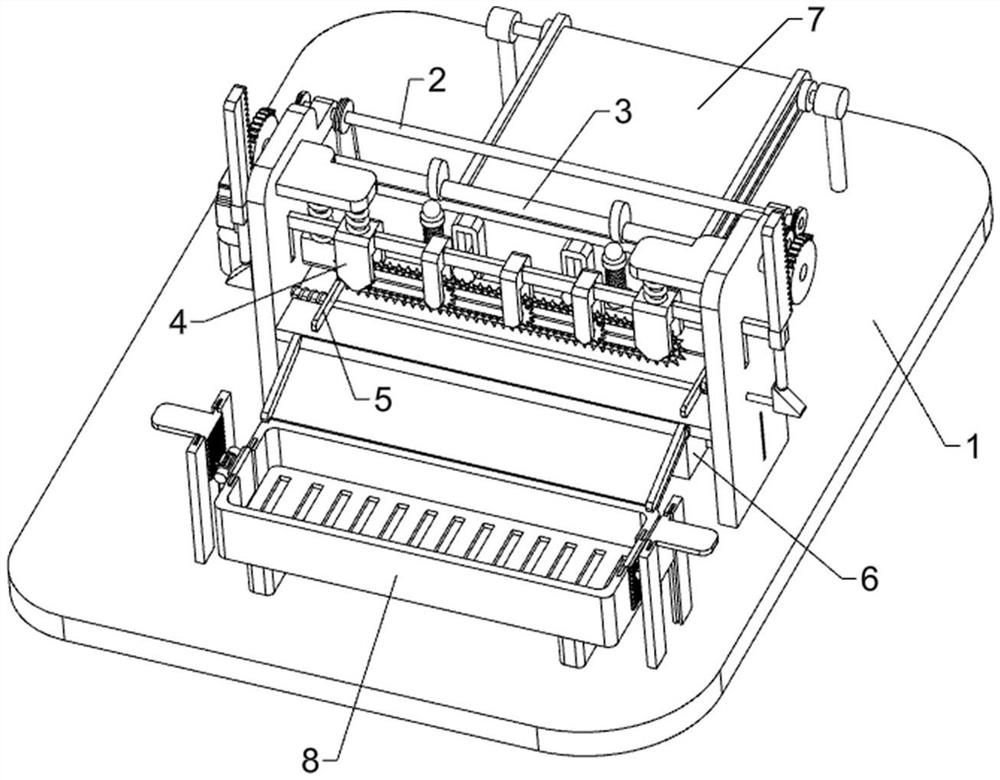

[0058] A blackboard plank cutting device with auxiliary positioning function, such as Figure 1 to Figure 3 As shown, it includes a base 1 , a driving mechanism 2 and a positioning mechanism 3 , the middle side of the top of the base 1 is connected with the driving mechanism 2 , and the driving mechanism 2 is connected with the positioning mechanism 3 .

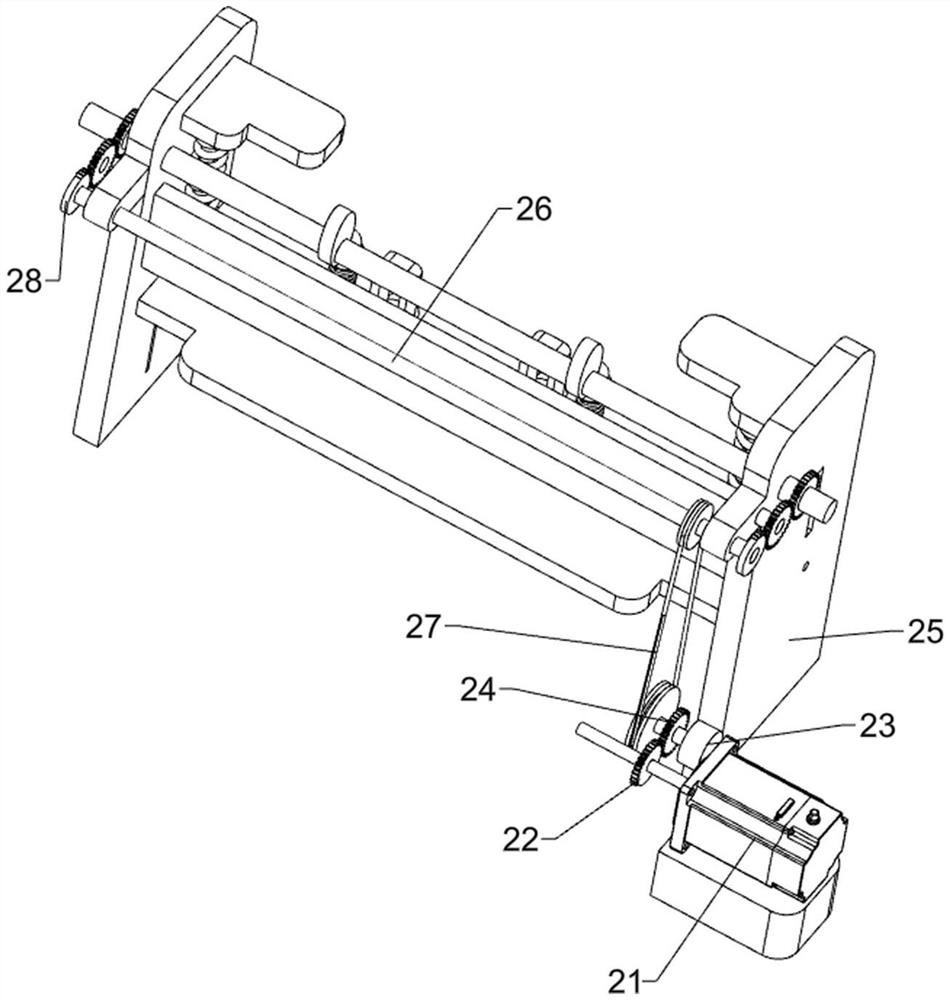

[0059] The driving mechanism 2 includes a servo motor 21, a first missing gear 22, a first fixed rod 23, a first gear 24, a fixed frame 25, a first rotating shaft 26, a first transmission assembly 27 and a second missing gear 28, and the top of the base 1 The left side is provided with a servo motor 21, the output shaft of the servo motor 21 is connected with a first missing gear 22, the top of the base 1 is provided with a first fixed rod 23, and the right side of the first fixed rod 23 is connected with a first gear 24 in a rotational manner , the first gear 24 meshes with the first missing gear 22, and the middle side of t...

Embodiment 2

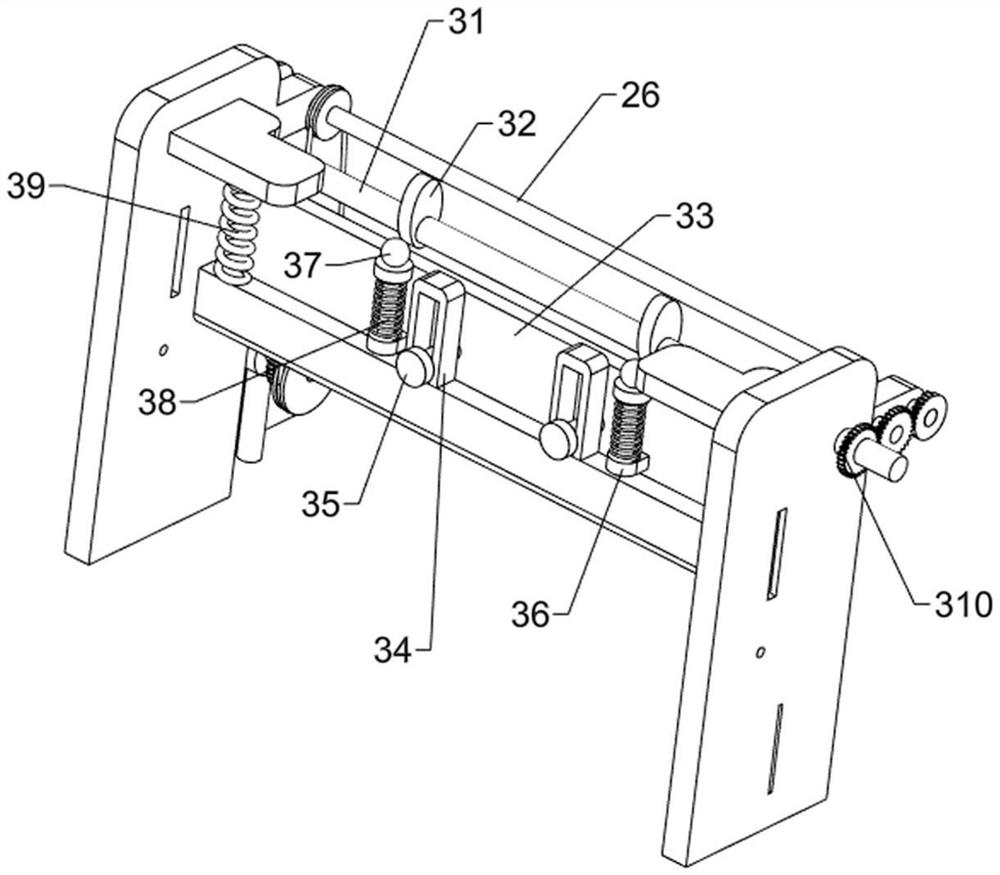

[0063] On the basis of Example 1, such as Figure 4 to Figure 7 As shown, a cutting mechanism 4 is also included, and the cutting mechanism 4 includes a third missing gear 41, a slide bar 42, a rack bar 43, a second fixed block 44 and a cutting assembly 45, and the two ends of the second rotating shaft 31 are connected with The third gear 41 is missing, a slide bar 42 is slidably connected between the left and right sides of the fixed frame 25, the left and right sides of the top of the slide bar 42 are connected with a rack bar 43, and the slide bar 42 is connected with five second fixed blocks 44 A cutting assembly 45 is rotatably connected between the lower parts of the second fixing block 44 , and the tops of the second fixing blocks 44 on the left and right sides are elastically connected to the inner wall of the fixing frame 25 .

[0064] Also includes a clamping mechanism 5, the clamping mechanism 5 includes a push block 51, an inclined block 52 and a third spring 53, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com