A kind of butt joint construction method of FRP sand pipe

A technology of glass fiber reinforced plastic sand inclusion and construction method, which is applied in the directions of pipes/pipe joints/pipes, pipes, rigid pipes, etc., can solve the problems of difficulty in ensuring the construction quality of joints, ovality of leaking sockets, small compression ratio of sealing rings, etc. To achieve the effect of simplifying the sealing processing operation, improving the sealing effect, and reducing the processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

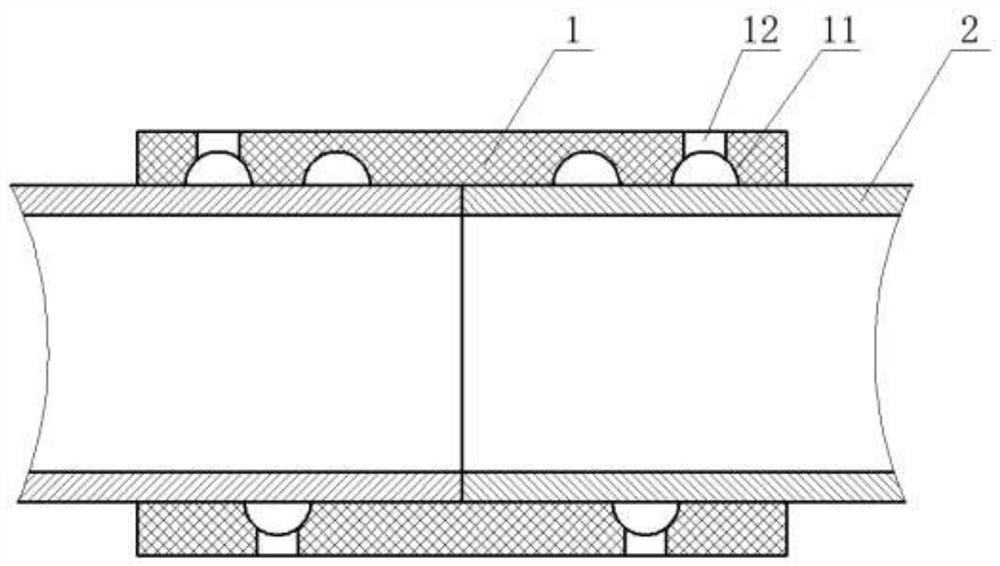

[0032] Such as figure 1 As shown, the present invention provides a butt joint construction method of FRP sand pipes, comprising the following steps:

[0033] Prepare the sleeve pipe 1, the left and right ends of the inner peripheral surface of the sleeve pipe 1 are respectively provided with filling ring grooves 11, and each filling ring groove 11 is provided with at least one grouting hole 12, and the grouting hole 12 extends to the bearing On the outer peripheral surface of the casing 1, insert two FRP sand-filled pipes 2 with the same outer diameter into the casing 1 from the left and right ends of the casing 1 to make them dock in the casing 1, and then pass through the grouting hole 12 Fill in an appropriate amount of sealing mortar, and the construction will be completed after the sealing mortar is condensed.

[0034] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com