Method for preparing cannabidiol by decarboxylation of cannabidiolic acid in industrial hemp

A technology of cannabidiolic acid and cannabidiol, which is applied in the field of extraction and purification of plant components and achieves the effects of low operating temperature, high efficiency and less peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing cannabidiol from cannabidiolic acid decarboxylation in industrial hemp, the method being specifically:

[0027] Step 1: Processing of industrial hemp flowers and leaves: Harvest industrial hemp flowers and leaves at maturity, wash and remove impurities, then dry at natural temperature, crush, pack, and store at low temperature for later use; the function of this pretreatment step is to clean Clean is conducive to the uniform transmission of microwave radiation cracking energy;

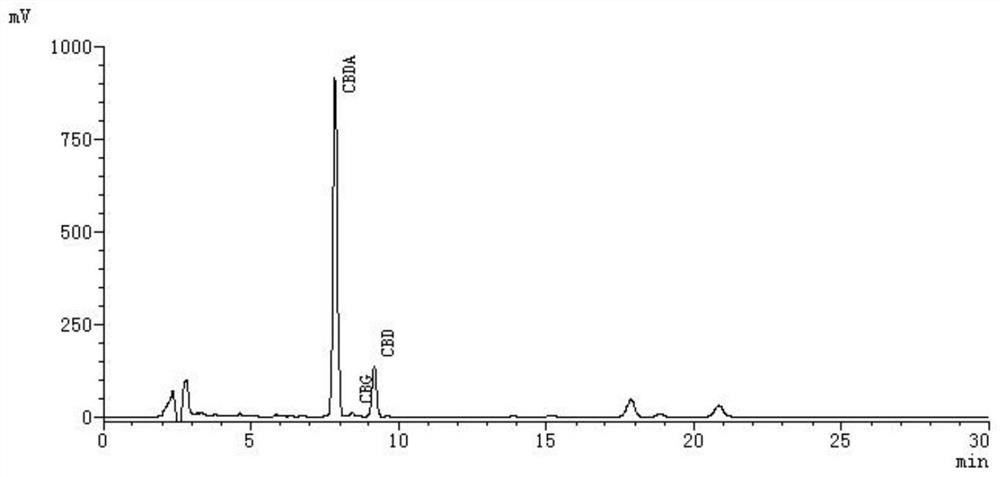

[0028] Step 2: Microwave radiation cannabidiolic acid decarboxylation method: Weigh 100g of the processed industrial hemp mosaic leaf sample and put it into a 1L raw material kettle. The experimental parameters are set to microwave radiation temperature of 40°C, microwave power of 300W, and time of 30 minutes.

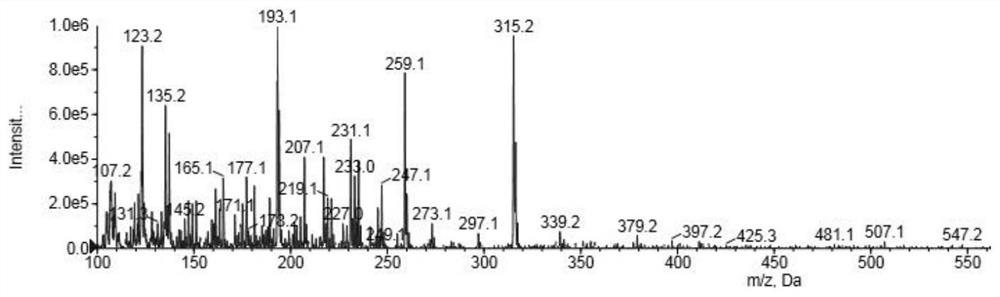

[0029] Detect the content of cannabidiol: the specific chromatographic conditions are: chromatographic column: C18 (150mm×4.6mm, 5μm); mobile phase: nitrile-water ...

Embodiment 2

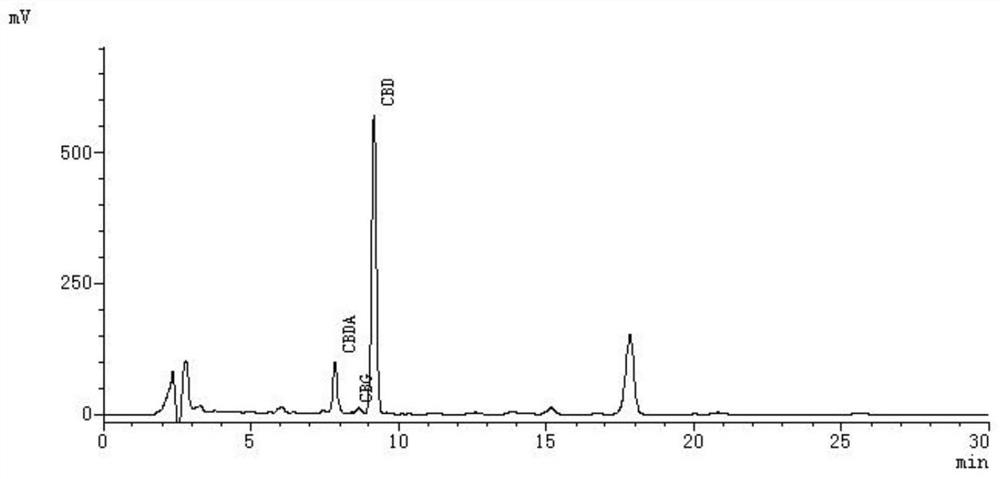

[0031] The difference between this embodiment and the embodiment 1 is that in the second step, the experimental parameters are set as the microwave radiation temperature of 40° C., the microwave power of 450 W, and the time of 30 minutes.

Embodiment 3

[0033] The difference between this embodiment and the embodiment 1 is that in the second step, the experimental parameters are set as the microwave radiation temperature of 40° C., the microwave power of 600 W, and the time of 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com