Steel for 40CrNiMo high-strength bolt and preparation method of steel

A technology of high-strength bolts and steel ingots, applied in the field of medium-carbon high-strength alloys, can solve the problems of unfavorable scale and economy in the field of high-strength bolts, the inability to apply in the field of ordinary fasteners, and the impact of no mention, so as to improve the comprehensive yield of products , Avoid white spot precipitation, improve the effect of cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The above-mentioned 40CrNiMo high-strength bolt steel can adopt the following preparation method, comprising the following steps:

[0047] S1: According to the above-mentioned metering ratio of steel elements, the molten steel is obtained by electric furnace smelting and out-of-furnace refining;

[0048] S2: performing vacuum degassing on the molten steel, and then performing die casting to obtain a die cast steel ingot;

[0049] S3: The die-cast steel ingot is rolled into a billet with a 750 rolling mill, and the first billet is rolled and then cooled slowly;

[0050] S4: hot rolling the bloom to obtain the 40CrNiMo high-strength bolt steel.

[0051] The specific operation of step S1 is:

[0052] Electric furnace smelting is used to remove P in the slag during the oxidation period, and the slag is clean. After the slag is discharged, deoxidizer and lime are added to make the slag uniform; the end point [C]≤0.05%, [Si]≤0.05%, and the tapping temperature is 1640~1690℃ ;...

specific Embodiment

[0061] Table 1 is a process parameter table

[0062]

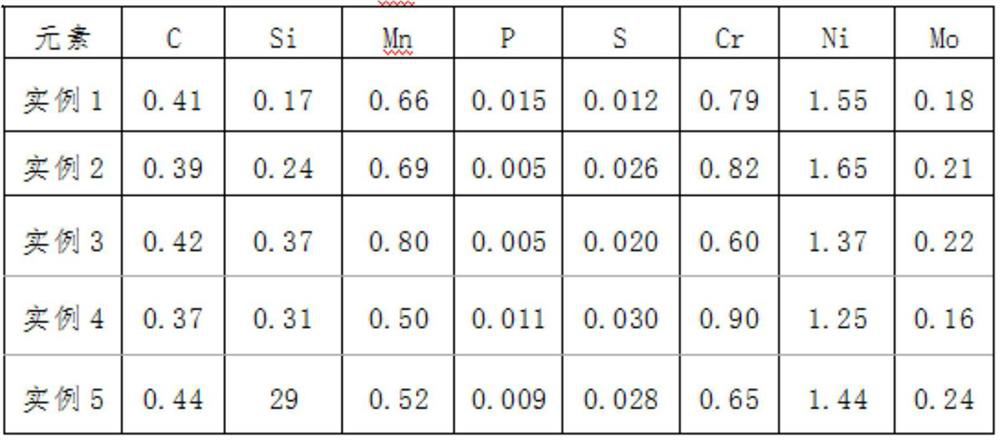

[0063] Table 2 is the chemical composition of each embodiment

[0064]

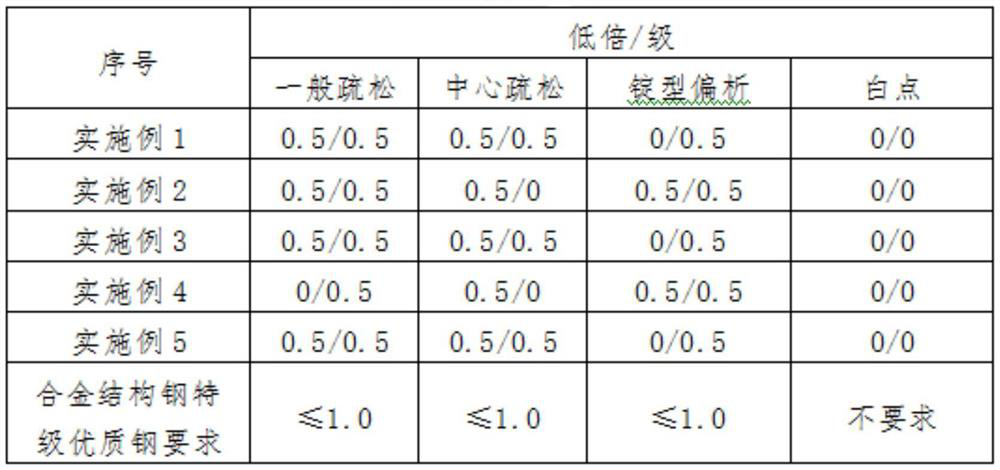

[0065] Table 3 is the low power tissue

[0066]

[0067] Table 4 is the performance of high-magnification tissue

[0068]

[0069] Table 5 is the mechanical properties

[0070]

[0071] The tensile strength and yield strength of the steel grade of the invention are far greater than the standard lower limit, and can fully meet the use requirements in the field of high-strength bolts. In addition, compared with the prior art (publication number CN103627969, publication number CN106435332), in the case of similar performance parameters, the preparation process is simpler and the production cost is greatly reduced. In addition, the addition of sulfur in the material greatly improves its cutting performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com